Manual

Drilling Cycles

Chapter 26

26-15

6. After the drilling tool retracts an amount d, it then resumes drilling at

the cutting feedrate to a depth d + Q.

This retraction and extension continues until the drilling tool reaches

the depth of the hole as programmed with the Z-word in the drilling

cycle block.

7. The drilling tool then retracts at a rapid feedrate to the initial point

level as determined by G98.

When the single block function is active, the control stops axis motion and

awaits “cycle start” after steps 1, 2 and 7.

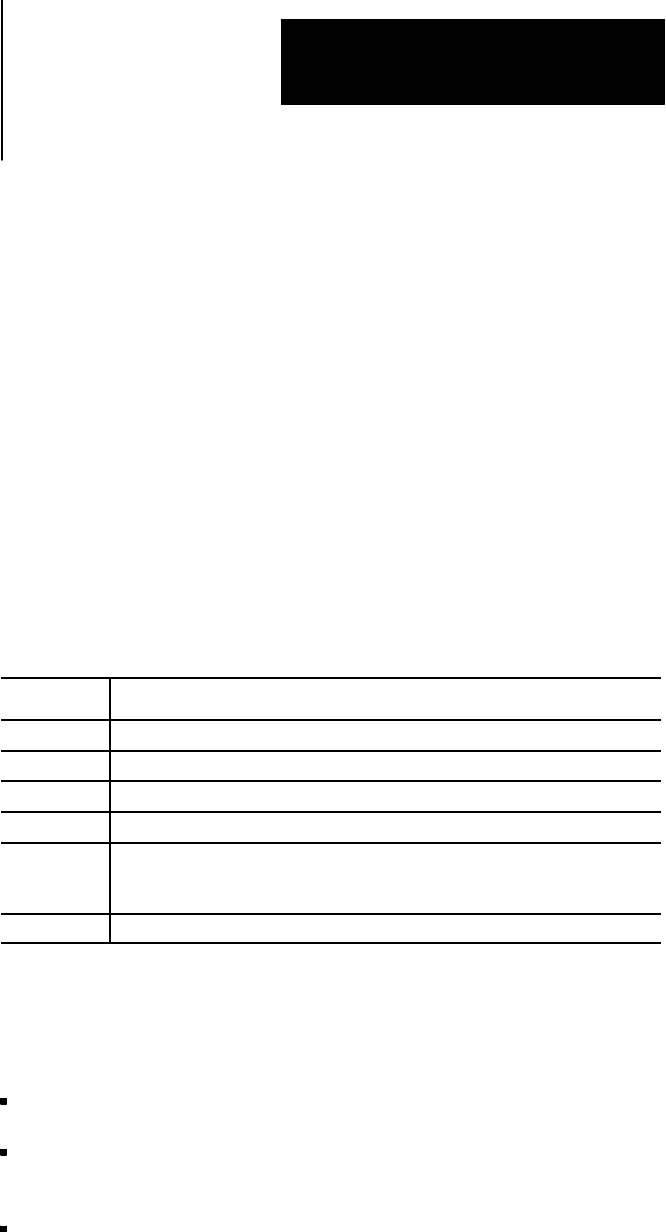

Use this cycle to cut right-handed threads. The format for the G84 cycle

is:

G84X__Z__R__P__F__L__;

Where : Is :

X specifies location of thehole.

Z defines the holebottom.

R defines the Rpoint level.

P defines the dwellperiod at holebottom.

F defines the cuttingfeedrate andrepresents thethread leadalong thedrilling axis

(Z in this manual). It is mandatorywhen cuttingany threads. The control

interprets theF-word asthe numberof threads perinch ormillimeter.

L defines the numberof times thedrilling cycleis repeated.

See section 27.3 for a detailed description of these parameters.

Important: When programming and executing a G84 tapping cycle,

remember:

the programmer or operator must start spindle or live tool rotation

override usage - the control ignores the feedrate override switch and

clamps override at 100 percent

during tapping, the feedrate override switch and the feedhold feature are

both disabled; cycle stop is not acknowledged until the end of the return

operation

(G84): Right-Hand Tapping

Cycle