Manual

Drilling Cycles

Chapter 26

26-20

Use this cycle to cut right-handed threads.

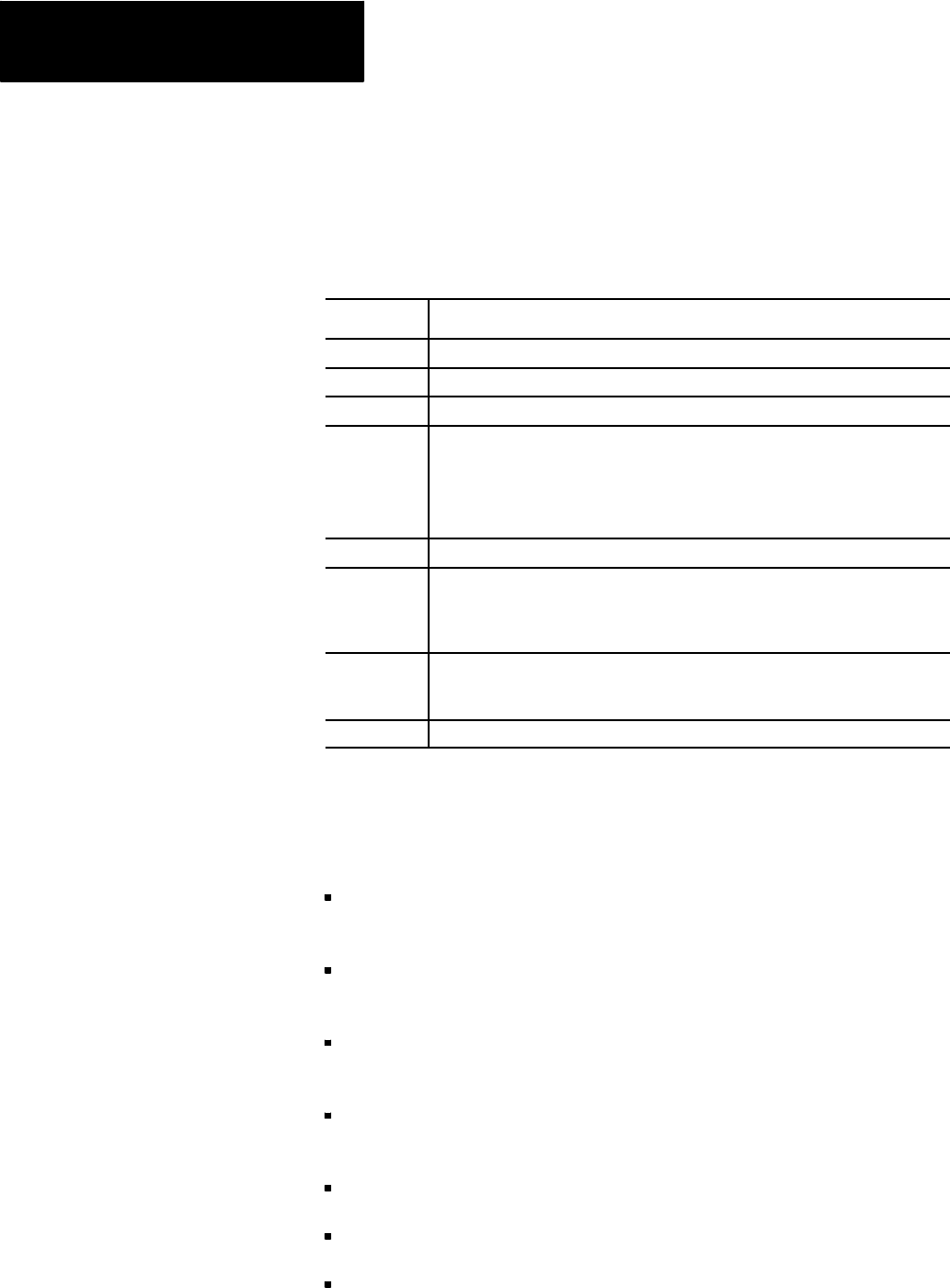

The format for the G84.2 cycle is:

G84.2X__Z__R__F__L__Q__D__S__;

Where : Is :

X specifies location of thehole.

Z defines the holebottom.

R defines the Rpoint level.

F defines the threadlead alongthe drilling axis (Zin thismanual). It is mandatory

and modal in anysubsequent solid tappingcycle blocksuntil anew F-wordis

programmed.

The control interprets theF-word asthe threadlead ininches per revolutionor

millimeters perrevolution, depending onthe inch/metricmode active.

L defines the numberof times thedrilling cycleis repeated.

Q

defines theangle at whichto orient thespindle before starting the tap. It ismodal

in any subsequent solid tappingblocks untila newQ-word isprogrammed orthe

tapping cycle is cancelledby aG80. To retapa hole, aQ-word must have been

programmed when the hole was originallytapped.

D

defines thereturn spindlespeed, but cannot exceed themaximum tapping

spindle speed set in AMP. This will adjust yourZ-axis feedrateaccording tothe

thread lead defined in F.

S

defines spindlespeed inrpm.

See section 27.3 for a detailed description of these parameters.

Important: When programming and executing a G84.2 solid-tapping

cycle, remember:

the feedrate of the tapping phases is derived as

(spindle {RPM}

*

F-lead {IPR}) = IPM

the spindle speed that is active at the start of the cycle determines the

effective Z feedrate

the direction of spindle rotation for tap-in and tap-out phases will be

automatically generated by the control

spindle speed override has no effect on the solid-tapping cycle; you can

use feedrate override to adjust the tapping operation

D cannot exceed the maximum tapping spindle speed set in AMP

you cannot select tools via D-word while in solid-tapping mode

gear changes are locked out

(G84.2): Right-Hand

Solid-Tapping Cycle