Manual

Chapter 30

Using a 9/Series Dual--Processing System

3

0

-

6

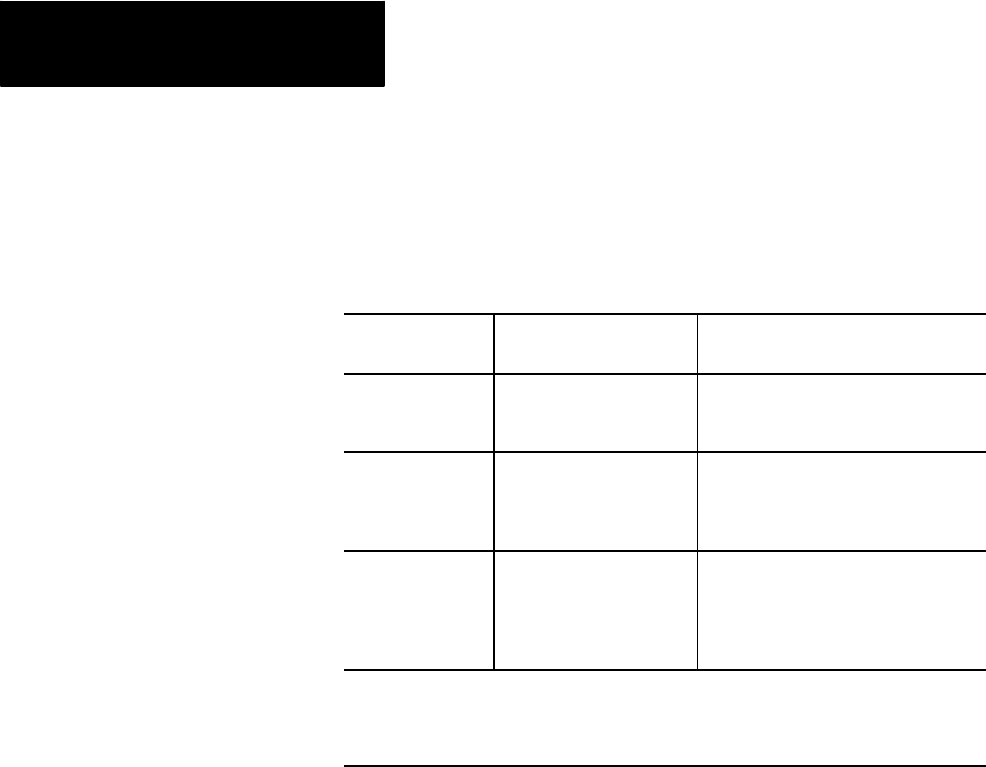

Reset Operations

Dual-process systems have a process reset operation, in addition to the

normal block reset and control reset functions. These reset operations

work as follows:

If you want to

perform a:

Press: The control will:

Block Reset [RESET] Skip thecurrently activeblock inthe

currently selectedprocess

(see chapter 2).

Control Reset [SHIFT] +[RESET] Return the control tothe default settings,

clear anyprogram errors, and cancel

MDI commands inall processes

(see chapter 2).

¶

Process Reset [SHIFT] +

[PROC SELECT]

Return the program of thecurrently

selected process to thefirst block. Does

not affect theadditional processes(only

works onprograms executedfrom

control memory).

¶ If onlyone (or both)processes arestill executingtheir part program when a control

reset is performed, onlyprocesses not currentlyexecuting apart program will havea control

reset performed. A message willoccur in the processes executingthe programstating that a

control reset isnot allowed onthat process.

Communication Between Processes (Shared Paramacro Parameters)

A link between the different processes of the machine is provided with the

dual-process shared paramacro parameters. These parameters are available

only on dual-process lathe systems. They provide a link through which

common data can be passed between the different part programs executing

in the different processes of the machine. The shared dual-process

parameters are paramacro parameter numbers:

#7100 to #7199

Refer to page 28-33 for details on these paramacro parameters.