Manual

Chapter 30

Using a 9/Series Dual--Processing System

3

0

-

3

7

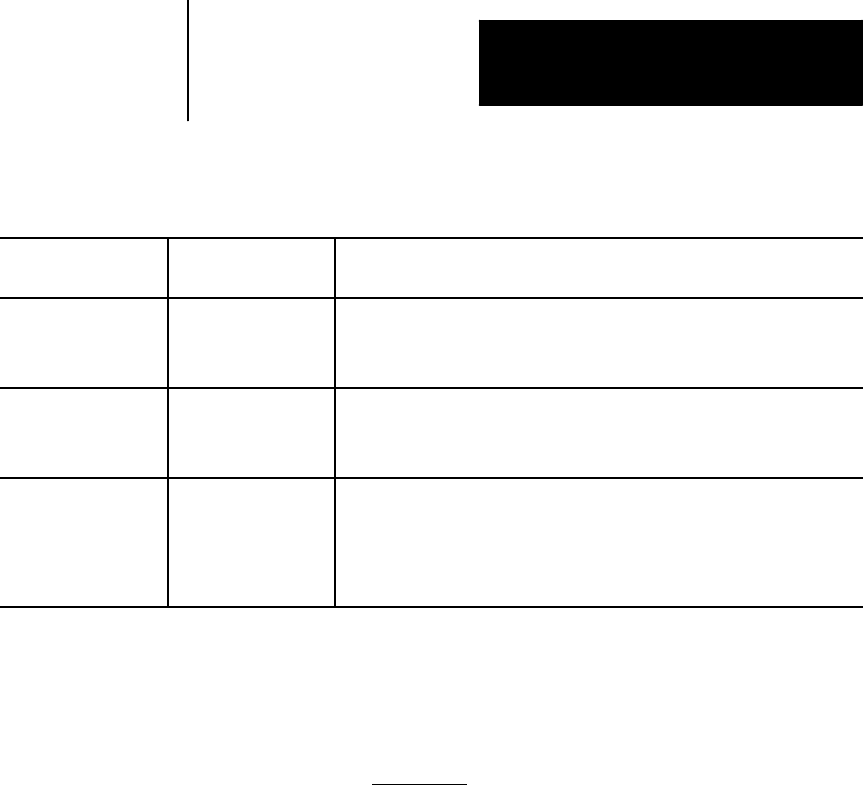

Example 30.10

Changing Processes with Tool Offsets

Process One

Activates this Tool

Process Two

Activates this Tool

Shared Axis

T1010;

(controls sharedaxis)

T000; Process oneactivates tooloffset onshared axisas definedin AMP

(delayed/immediate shift/move). When processtwo takescontrol of the

shared axis, the shared axis tool offset is canceledon theshared axisuntil it

is returnedto theprocess.

T1111;

(controls sharedaxis)

T1111; Hassame offset for both processes. When youshift the sharedaxis between

processes, the offset remains active on theaxis. When theshared axis

changes processesthe tooloffsetsare re-initializedand the AMP selected

activation method (delayed/immediate shift/move) still occurs.

T1111; T2222;

(controls sharedaxis)

Process twoactivates tooloffset onshared axisas definedin AMP

(delayed/immediate shift/move). When you switch theshared axisto

processes one, theoffset changesto thetool offset value requestedin

process one. Since theoffsetsare re-initialized when shared axeschange

processes, the AMP selected activationmethod (delayed/immediate

shift/move) still occurs.

The Dual--Axis feature allows the part programmer to simultaneously

control multiple axes while programming commands for only one. It

differs from the split axis feature of the control in that the split axis feature

is used to control a single axis positioned by two servo motors.

The dual--axis feature is especially useful for twin turret lathes and other

machines running with parallel cutting tools. Figure 30.15 shows a typical

configuration for dual axes.

30.7

Dual-Axes on a

Dual-Processing System