Manual

Error and System Messages

Appendix B

B-20

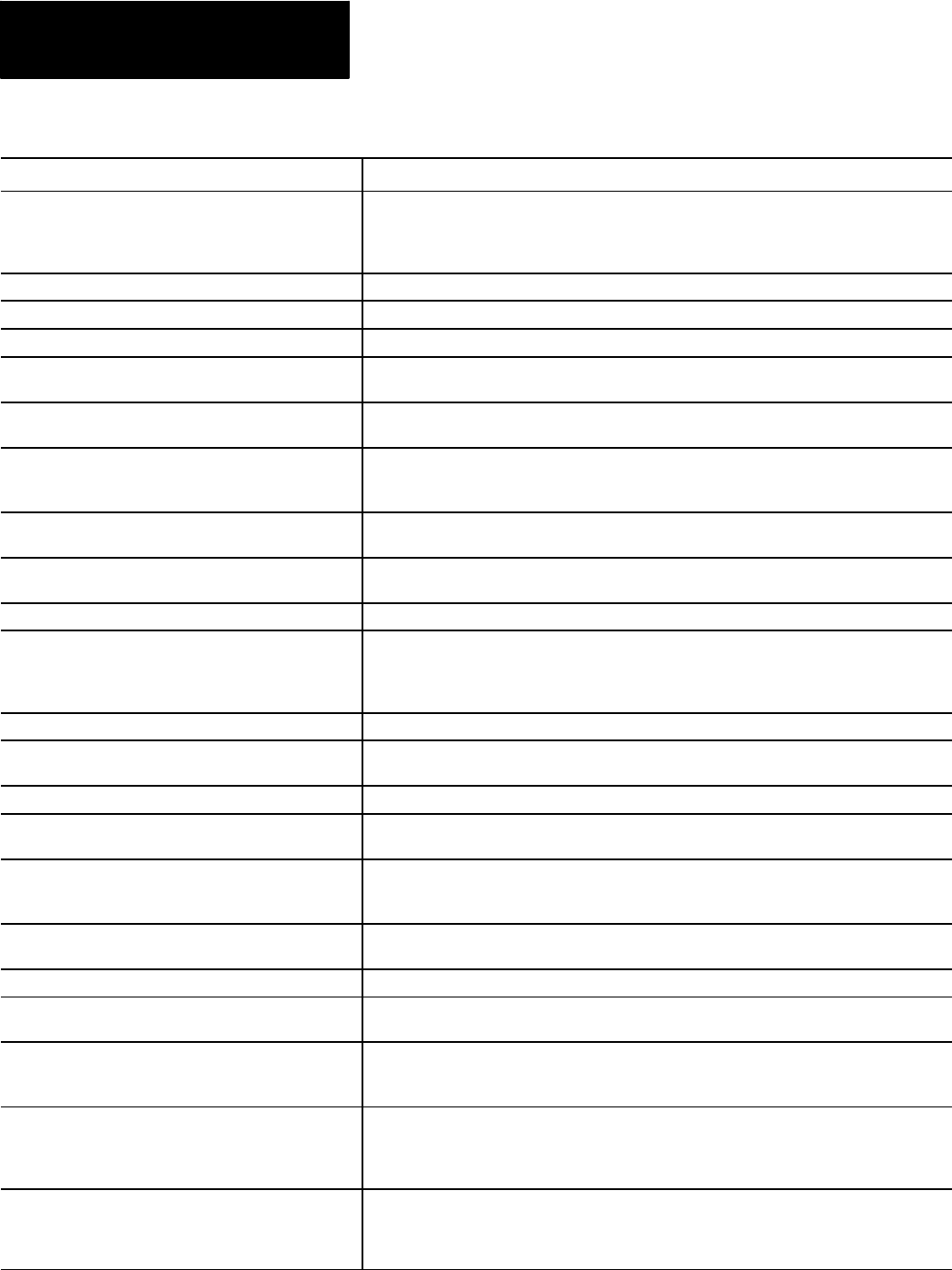

Message Description

INVALID CHECKSUM DETECTED This erroris commonfor several different situations. Most typically it results whenwriting or

restoring invalid data to flashmemory. For example if axiscalibration datais beingrestored to

flash and there was an erroror invalidmemory reference in theaxis calibration data file.

Typically this indicatesa corrupt orinvalid file.

INVALID CNC FILENAME An erroroccurred in G05DH+ communicationsblock.

INVALID CODE PROGRAMMEDFOR 7300 An invalidG or M codewas programmedduring 7300tape compatibilitymode.

INVALID COMMUNICATIONS PARAMETER Parametersin G05and/or G10.2 communicationblocks areincorrect.

INVALID CONTROL FORDUAL PROCESSSYS Thesystem executive downloadedto thecontrol doesnot match thehardware configuration

established by your option chip.

INVALID CUTTER COMPENSATION NUMBER A compensationnumber (or TTRCnumber) out of the rangeof allowable compensation

numbers (eithertoo largeor toosmall) was programmed.

INVALID CYCLE PROFILE Thepath definingthe cycleprofile isnot valid. This istypically causedby thecutter radius being

set to the wrong sign, being set toolarge, or the valuesfor U, W, I, K, and thecutter radius

combined are not valid for the profileto becut.

INVALID DATA AFTER A MACROCOMMAND Typically caused by a non-paramacrocommand followinga paramacro command. Macro and

non-macro commands cannot exist in thesame block.

INVALID DATA BEFORE A MACROCOMMAND Typically causedby anon-paramacro commandpreceding aparamacro command. Macro and

non-macro commands cannot exist in thesame block.

INVALID DATA FORMAT MUSTBE MM/DD/YY An invaliddate format wasentered. The format must beMonth / Day / Year (MM/DD/YY).

INVALID DEPTH PROBECONTROLLING AXIS Theaxis name which is AMPedas thecontrolling axisfor thedepth axisis not anaxis that has

been configured on the system or theadaptive depthcontrolling axisis configuredas thesame

axis definedto havedepth probefeedback. Refer to your AMPreference manualfor details on

axis configuration.

INVALID DESKEW MASTER TheAMPed namespecifying themaster deskew servois not oneof the AMPedaxes.

INVALID DESKEW SLAVE The AMPed name specifyingthe master deskewservo isnot one of theAMPed axes, or it has

already selectedas amaster axis.

INVALID DH COMMANDTYPE An error occurredin G05DH+ communicationsblock.

INVALID (DO) COMMAND NUMBER Thespecified loopnumber ina paramacroDO commandis out of thelegal range, or not found.

DO commands must be followedby a1, 2, or 3.

INVALID (END) COMMAND NUMBER A paramacroEND commandhas beenencountered without amatching DOor WHILE, or

outside the valid range. END commands must befollowed bya 1, 2, or 3, as programmed with

the corresponding DO command.

INVALID ENDPOINT ING27 BLOCK The positionprogrammed in the G27 block isnot the home position. The end-point of aG27

block must bethe machinehome position.

INVALID EXPECTED LIFE The datajust entered for theexpected life of the cutting tool fortool management isinvalid.

INVALID EXPECTED TOOL LIFE The current program isattempting toenter an invalidvalue forthe toolmanagement expected

life of a tool. Tool life is programmed ina G10block withan L-word.

INVALID FB COUNTS At power up thecontrol checksthe AMP configuredposition andvelocity feedbackcounts per

revolution. If either of these parametersare invalid(for this hardwaretype) this error appears

and the control isheld inE--Stop.

INVALID FDBK/MTR TYPECOMBO When changingbetween anexecutive from system 9.xxto 10.xx some majorchanges occurred

to how a servois configuratedin AMP. When copying this AMPproject from 9.xxto 10.xxyou

must open and reconfigure some of theAMP servo groupparameters beforesaving and

downloading to the control.

INVALID FILE TYPE Anerror has occurredin afile that hasbeen sent from theODS workstationto thecontrol.

Typically it is theresult of ODS sendingthe wrongfile typeto thecontrol (for example, anAMP

file is sent when aPAL download is taking place, etc.). Attempt to download the file again,

making sure that the correct file typeis selected when downloaded.