Manual

Error and System Messages

Appendix B

B-30

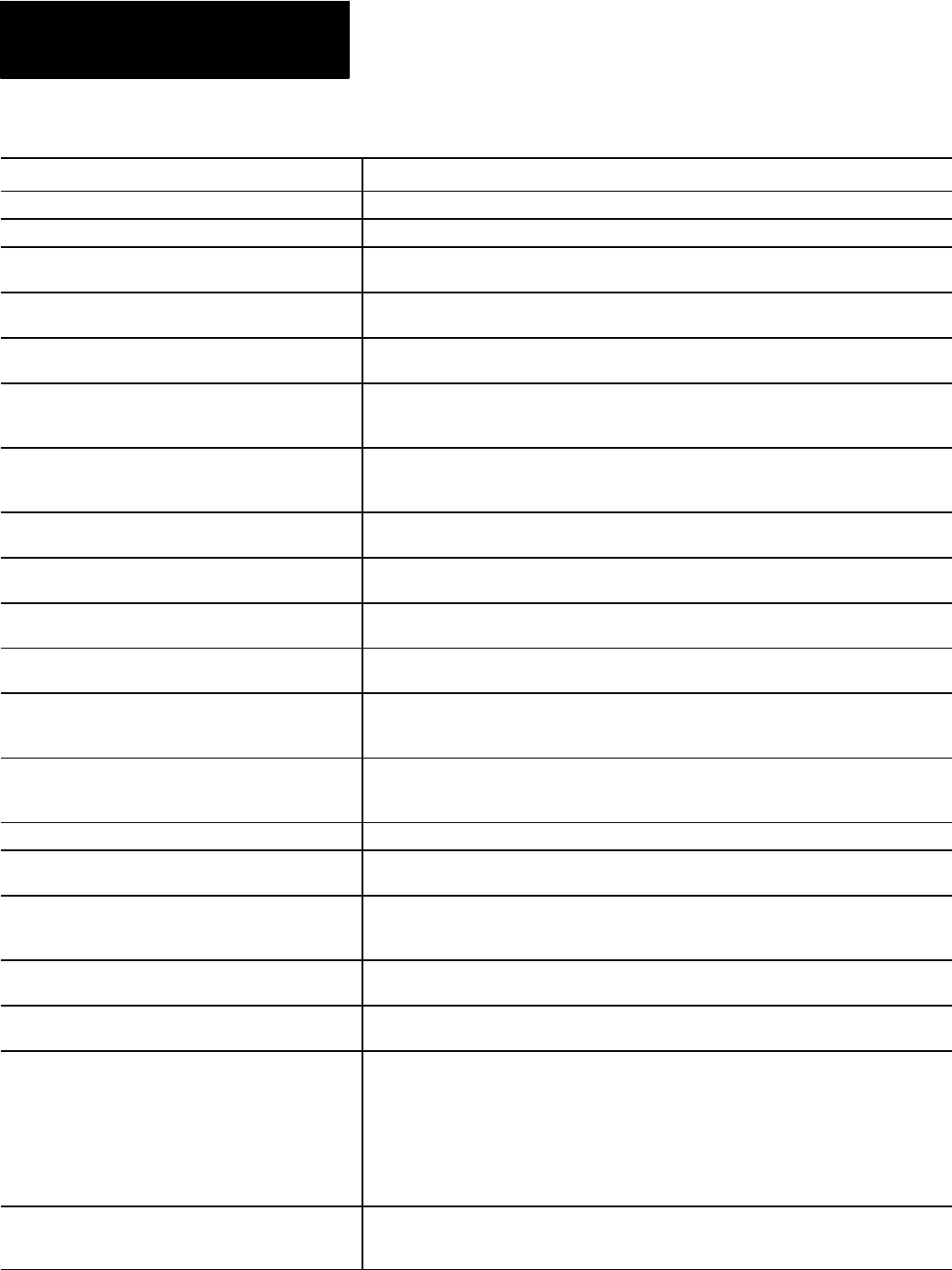

Message Description

NO PROGRAM TORESTART Thereis noprogram to restart. The previousprogram was eithercompleted orcancelled.

NO RECIPROCATIONDISTANCE A reciprocation interval of zero (0)was programmedfor a grinder reciprocation fixedcycle.

NO RECIPROCATIONFEEDRATE Thereciprocation feedrate, E-word, required during a grinder reciprocationfixed cyclewas not

programmed.

NO SPINDLE ASSIGNED TO THISPROCESS A process attemptedto activatevirtual or cylindricalmode andthat process hasno spindle

assigned to it via AMP.

NO STRING INPUT A program searchoperation wasrequested andno string to search for hasbeen entered. Key

in the required search string, andpress the [TRANSMIT] key to entera search string.

NO TOOL GROUP PROGRAMMED A blockthat loads datainto thetool management tabledoes not containthe parameter that

determines thetool groupnumber corresponding tothe other data inthe block. The group

number isprogrammed usingthe P-word.

NO TOOL NUMBER PROGRAMMED Ablock that loadsdata intothe toolmanagement table doesnot contain theparameter that

determines thetool number correspondingto theother datain theblock. The toolnumber is

programmed using the T-word.

NO UNEXPIRED TOOLAVAILABLE A request fora tool group wasmade, and allof the toolsin that tool management group have

expired their tool lives. Either reset the toollife for thetools, or install newtooling.

NON_CONSECUTIVE/TOOMANY FITTEDAXES More thanthe allowablenumber of axes mayhave beenassigned inAMP or anunfitted axis

was assignedbetween twofitted axes. You can assign onlyfitted axesconsecutively in AMP.

NON-LINEAR AXISIN PLANEDEFINITION Thecurrent axis plane is illegal becausea non-linearaxis (rotary) hasbeen assignedto the

plane in AMP.

NOT ALIGNED During the power--up alignment procedure, either the1326 motor(connected toa 9/440HR) is

misaligned or the SINCOS device’ s memoryis corrupt.

NOT ALLOWED IN ANGLEDWHEEL MODE The axes can not bemoving when you change toangled wheel mode. Also the axes involved in

angled wheel motion must behomed beforeyou canenter angledwheel mode. Other features,

such as block retraceor jog retract also must not be active when changing mode.

NOT ALLOWED - G41/G42 ACTIVE An attempt wasmade toperform some operation or program somefeature that cannot be

performed when cutter compensationor TTRC isactive (G41or G42). Cancel compensationby

programming a G40 block before performingthe operation.

NOT ALLOWED FROM MDI Certainprogramming commandsare not allowedfrom MDI (GOTO, WHILE, etc.).

NOT ALLOWED ON DUAL/SLAVE AXIS A G26 wasprogrammed ona dueledaxis. The G26feature isincompatible withthe dualaxis

feature.

NOT ALLOWED - THREADING ACTIVE An attempt wasmade toperform someoperation (typicallya spindlespeed adjustment) that is

not allowed when cutting a thread. This includes allforms of threading, includingsingle passor

multiple pass threads.

NOT IN G10L3 MODE A G11 blockwas programmedthat cancels G10L3data settingwhen thecontrol isnot in the

G10L3 data setting mode. G10L3 isused toset the toolmanagement table data.

NUMBER ISOUT OFRANGE Anattempt was made to perform acalculation usingthe paramacrofeatures or thecalculator

features that containsa numberlonger than11 characters.

NUMBER OFMOTORS/SPINDLECONFIG ERROR This iserror indicates AMPis incorrectlyconfigured for the9/Series hardware. Typical AMP

configuration errors that generate thiserror include:

You have AMPed more motorsthan thecurrent hardware supports.

You have indicated there areservo motorsattached toservo boardsthat don’t exist (the

9/230 and 9/440 are configuredas if they haveonly oneservo card).

You have configured too manyspindles (1 on 9/230, 2 on 9/260and 9/440, 3on 9/290).

Too few axes wereconfigured for theindicated number of motors on the boardsor

too few servos wereconfigured for indicatednumber of motorson theboards.

NUMERIC VALUE MISSING Thenumeric valueassociated withthe programmedword ismissing. There is anAMP

parameter that determineswhether a missingnumeric isassumed tobe zeroor if it will generate

this error.