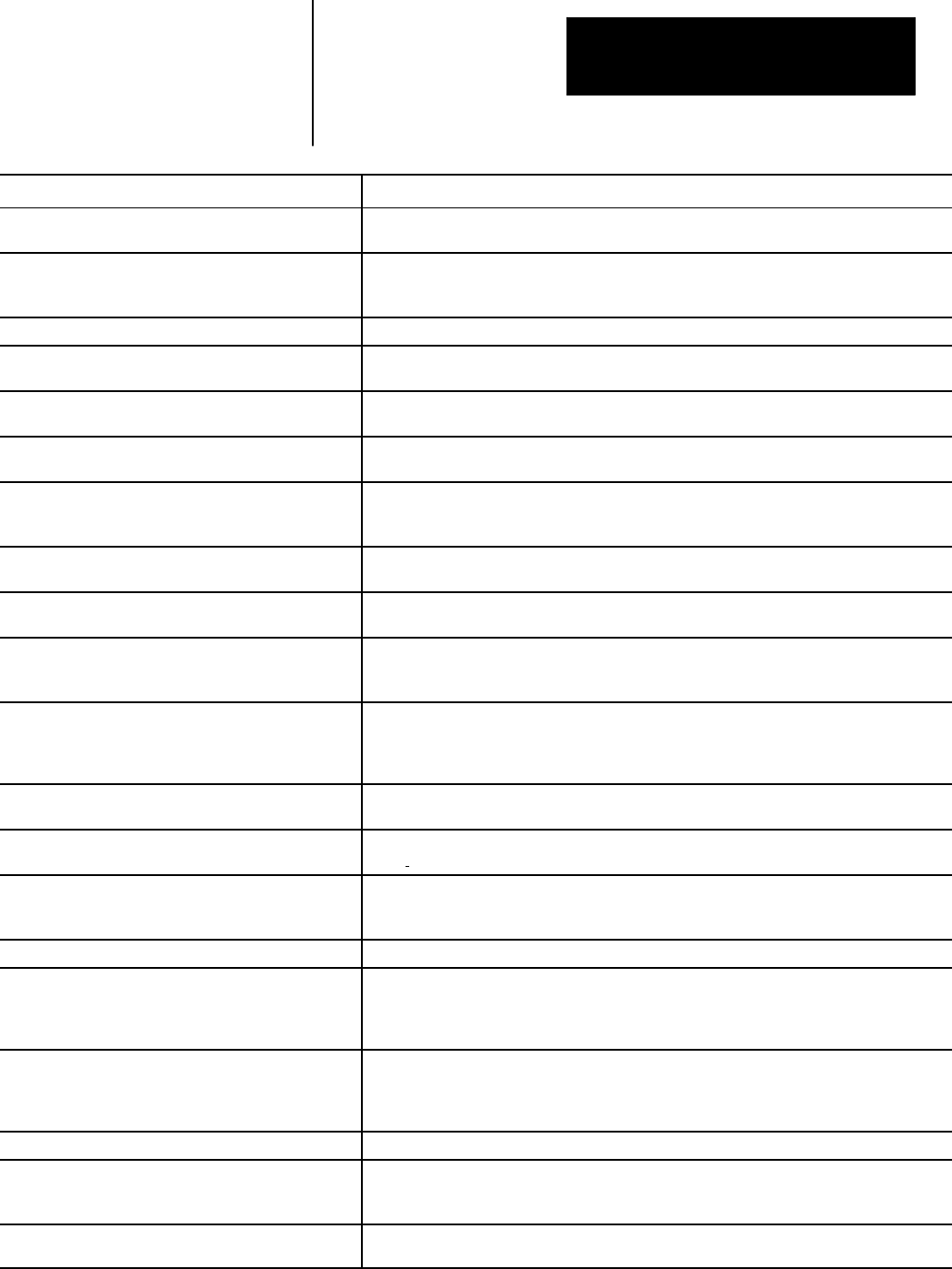

Manual

Error and System Messages

Appendix B

B-33

Message Description

PAL SOURCE REV. MISMATCH -- CAN’T MONITOR PAL sourcecode inthe controldoes not matchthe revisionof the CNCexecutive. The PAL

code may execute if allof the PAL system flags exist but themonitor cannot be used.

PAL USING MEMORY - REFORMAT The AMP parameter allowingPAL to be stored in RAM memory hasbeen enabled. This

changes theamount of RAM memory availablefor part program storage, requiringthe RAM disk

to be reformatted. Part programs should have been backed upprior to this.

PARAMETER ASSIGNMENT SYNTAX ERROR A blockthat assigns Paramacro parameters has beenentered incorrectly.

PARAMETER NUMBER NOTFOUND The AMPparameter number beingsearched for throughthe control’ s patchAMP utilitydoes not

exist in the system.

PARAMETER VALUE OUTOF RANGE The valueentered forthe selected AMP parameter orparamacro parameteris lessthan or

greater thanthe allowedlegal value.

PARENTHESIS INPUT ERROR Parentheses havebeen enteredincorrectly ina program blockor calculationoperation. Correct

the use of the parenthesis; verify they arein matchedpairs.

PARITY ERROR INPROGRAM A serialcommunications error hasoccurred. A dataparity error occurredwhile sendingor

receiving data. This can result in a corrupted file, or theentire datetransfer operation maybe

aborted by the control.

PARK AXIS MOTION NOTALLOWED Axis motion wasprogrammed fora parked axis ina dualaxis group. When bothmaster and

slave axes are parked, noaxis motionis allowedon aparked axisin adual group.

PART PROGRAM NOT SELECTED An attempt wasmade toexecute aprogram or checka program beforea programwas selected

for execution.

PART ROTATION FORMAT ERROR In part rotationblocks (G68, G69), onlyplane changesand modechanges includinginch/metric

and absolute/incremental are permitted. Any commandsother than normal motion commands

and the motion G-codes (G00, G01, G02, and G03)are not permitted.

PASSWORD PROTECTED Whenassigning password protectable features to an access level, anattempt was madeto

assign a feature to adifferent access levelwhen the currently activepassword doesnot have

access tothe feature. You can assign features to other access levels onlywhen you have

access tothat feature yourself.

PEAK CURRENTNOT 300% The axis for a 1394 or 9/440is not AMPedto havethe PEAKCURRENT set to300%. This

misconfiguration forces the controlinto E--Stop.

PERIPHERAL DEVICE ERROR An illegalcommunication attempt wasmade witha peripheraldevice, for example, attempting to

output to a tape reader or input from atape punch.

PLANE SELECTERROR An attempt wasmade tochange planesduring cuttercompensation (TTRC), betweenQPP

blocks, or betweenchamfer and corner roundingblocks. This erroralso willoccur if G17or G19

planes areselected ona lathe.

PLEASE WAIT FORCLEARING OFPAL MEMORY PAL isbeing erasedin preparationfor a PAL download.

PLUNGE MOTIONNOT ALLOWED The finalplunge positionmust be different from the start point of thecycle. This message can

occur if theplunge axisis not programmedin theentry block toG89 mode, or if the plungeaxis

increment is zero, orif the finalplunge axisposition is the sameas thestart point of the cycle

block duringG89 mode.

PLUNGE MOTIONNOT PROGRAMMED In yourpocket cycle youhave either not programmed afinal depth, or thefinal depthyou have

programmed is equal tothe depthof the cuttingtool at thestarting point of thecycle. The

location of the cutting tool when thepocket cycle isprogrammed must be at a different depth

than the final programmeddepth of thecycle.

PLUNGE NOTALLOWED A plunge that will cut into thepocket wall wasrequested ina G89irregular pocket cycle.

PLUNGE STEPSMIS--PROGRAMMED Therough, medium, and fine-feed depths inthe cycleblock arenot programmed correctly. This

is possibleif the datain theblock isincorrect or if the data inthe modalvalues of theparameter

not programmed in the block are incorrect.

POCKET END NOT SAMEAS START A pocket end-point that is not thesame asthe pocket start-point wasprogrammed in a G89

irregular pocket cycle.