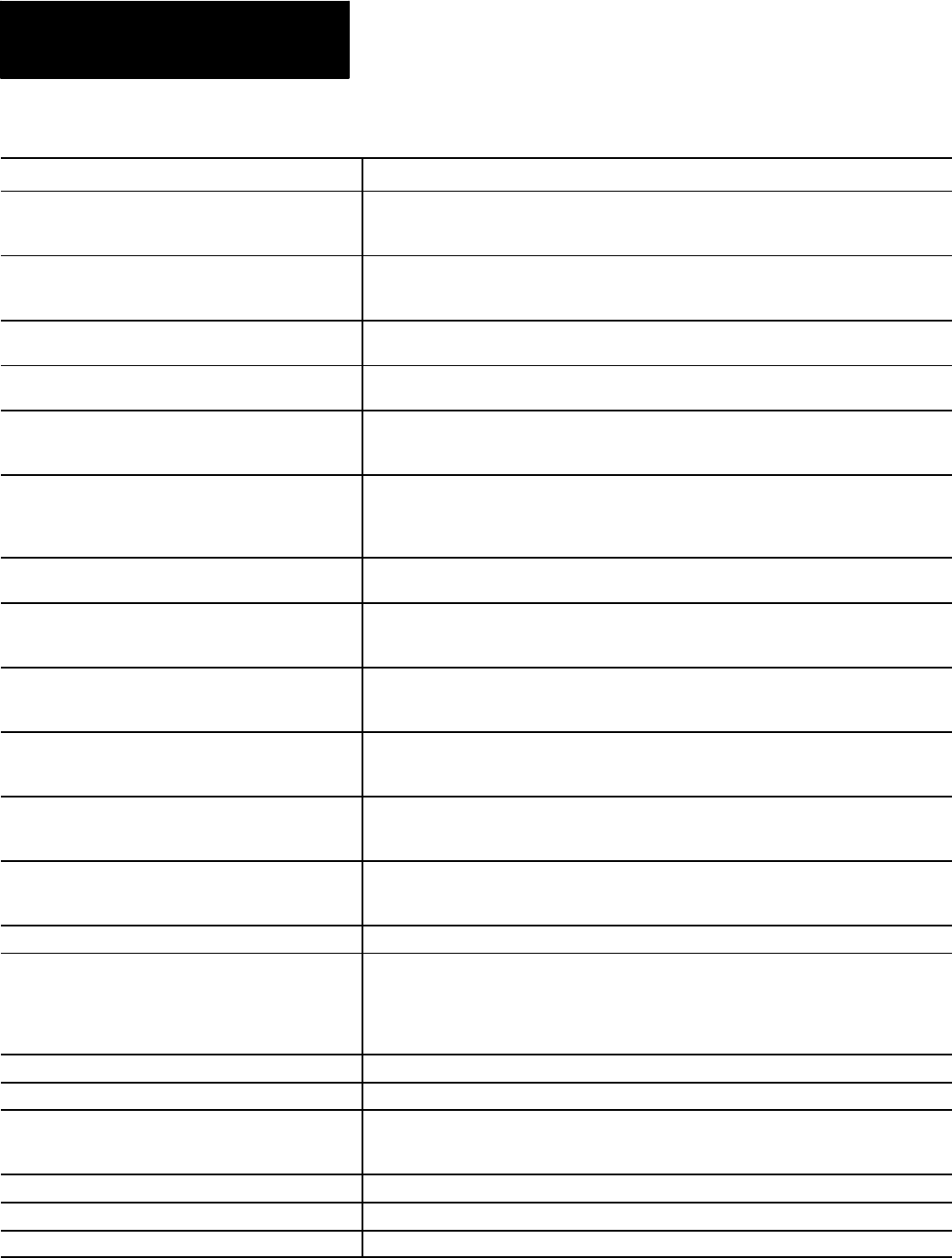

Manual

Error and System Messages

Appendix B

B-40

Message Description

SERVOPROCESSOR OVERLAP The analogversion of theservo sub-systemprovides fineiteration overlapdetection. This

message is displayed if thefine iterationsoftware on the DSP does not executeto completionin

one fine iteration.

SERVOPROM CHECKSUM ERROR Thechecksum test on theservo processorsoftware stored in PROM memory hasfailed. This

test is performedon power-upand periodicallywhile the system isrunning. Contact

Allen-Bradley customersupport services.

SERVOPTODIAGNOSTICS FAIL The servocard hasfailed itspower-up diagnostics. Consult Allen-Bradley customersupport

services.

SERVOPTOSEQUENCE ERROR The servo card has failedits power-updiagnostics. Consult Allen-Bradley customer support

services.

SERVOTIME-OUT READING ABSOLUTE ENCODER During power-upinitialization of theposition registersor duringa homingoperation, the servo

processor hasfailed toreturn aread withinthe requiredtime after theabsolute positionhas

been requested by themain processor. Consult Allen-Bradley customer support services.

SERVOTIME-OUT READING FEEDBACK During a homing operation, if there is anerror readingfeedback from theservo module, this

message appears. This usually occurswhen thesystem scantime isclose tothe thresholdat

which PALexecution can just complete and whenhoming morethan 3axes at atime. This

error canbe avoidedby homingaxes individually orincreasing thesystem scantime inAMP.

SET ZERO NOT ALLOWED ON: A set zerooperation onthe specifiedaxis isnot permitted. Typically thisis becauseeither the

control isnot in manualmode, or the selected axisis in the process of beingjogged.

SHAFT VALUE> NUMBER OF POCKETS Anattempt was madeto assigna shaft pocket that isgreater than the number of pockets

assigned for that custom tool. The shaft pocket numbermust be avalue between1 andthe

number of pocketsassigned tothat tool.

SHARED AXISCONFIGURATION ERROR Either thereare toomany sharedaxes configured, ashared axishas thesame nameas some

other axisin thesystem, the diameter axeson alathe areshared axes, orsome other

miscellaneous configurationerror occurred.

SHARED AXISNOT INPROCESS You haveattempted toposition ashared axis(or recouplea shareddual axis) not currently

available to the requesting process. A shared axiscan onlybe positioned by theprocess

currently controllingthe sharedaxis.

SHARED SPINDLECONTENTION Thisis a run-time decodeerror. A process attemptedto activatean exclusive-usespindle mode

or changethe spindlespeed whenanother process wasusing it. The processgoes intocycle

stop.

SHIFT AWAY FROM ENDPOINT When a cylindrical grinder cycle (G84 or G85) isprogrammed witha shift andplunge, and the

shift increment does not movetowards thecycle endpoint, thismessage isgenerated. The shift

increment must move towards the cycleendpoint.

SHIFT VALUEHAS TOO MANYDIGITS Youhave usedincorrect search stringsyntax inthe PAL searchmonitor utility.

SKIPPING SOURCE NOT INCLUDEDMODULE(S) When youdownloaded your PAL programthe source code for some moduleswas not included.

The ODS software candecide tonot include thesource onselected moduleswhen it determines

their isnot sufficient memoryon thecontrol to hold boththe PAL imageand thesource code.

The PALsearch monitor utility will not monitorany PAL modulesthat do not havetheir source

code downloaded.

SLASH NOTALLOWED An erroroccurred inG05 DH+communications block.

SLAVE AXIS LETTER CANNOTBE PROGRAMMED An attempt wasmade, when usingdual axes, toprogram the slave’ s axisletter.

SPINDLE CONFIGURATION ERROR An attempt wasmade toconfigure aspindle that didnot have aservo boardidentified inAMP to

indicate to which board thespindle isconnected. The spindlemust be includedin the

number--of--motors AMPparameter for theboard thespindle ison.

SPINDLE ERROR, AMPFIRST SPINDLE1ST AMP order of spindles must bespindle 1, spindle2, spindle 3.

SPINDLE ERROR, AMPSECOND SPINDLE 2ND AMP order of spindles must bespindle 1, spindle2, spindle 3.

SPINDLE ERROR, AMPTHIRD SPINDLE 3RD AMP order of spindlesmust be spindle1, spindle 2, spindle3.