Manual

Error and System Messages

Appendix B

B-42

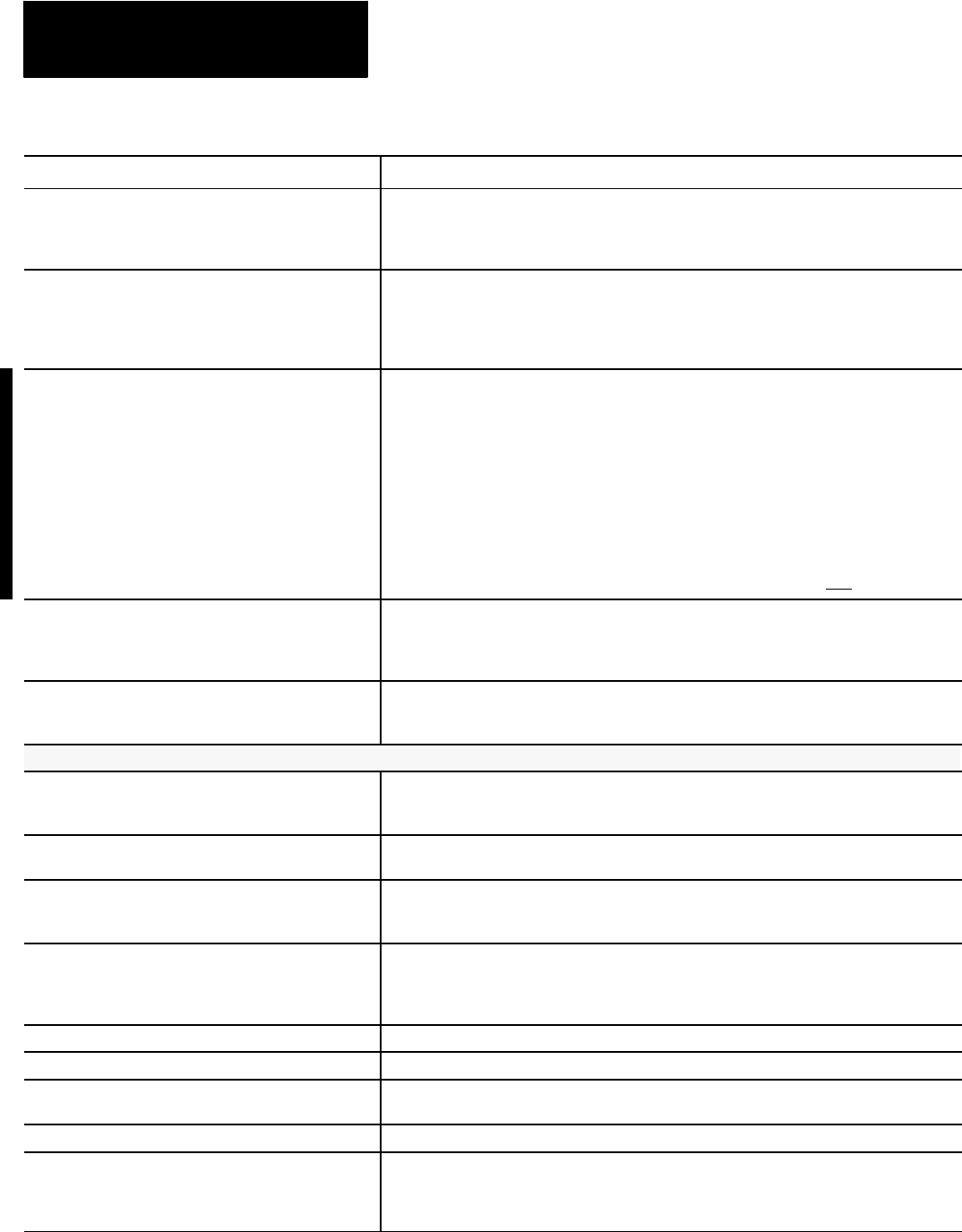

Message Description

SYSTEM MODULE GROUNDFAULT The1394 system module hasdetected aground fault. The system generatesa groundfault

when there is animbalance inthe DC bus of greater than5A. This drive errorcan becaused by

incorrect wiring (verify motor and ground wiring), motor malfunction, or anaxis moduleIGBT

malfunction.

SYSTEM MODULE OVERTEMP The1394 containsa thermalsensor which sensesthe internalambient temperature. Causes

could be: that the cabinet ambient temperature is above rating. The machine duty cycle

requires anRMS current exceedingthe continuousrating of thecontroller. The airflowaccess to

the 1394 is limitedor blocked. This does not necessarilyindicate a motor over temperature.

Motor over temperturesensors shouldbe wireddirectly intothe E-Stopstring.

SYSTEM MODULE OVERVOLTAGE The 1394 system modulebuss voltageexceeds the maximum operating voltage. The dcpower

bus iscontinuously monitored. If it exceeds apreset level (810V dc), afault is sensedand the

power supplyis disabled. There areseveral possible causes for this error.

·an undersizedshunt requirement

·a blown shunt regulator fuse

·a malfunctioning shunt regulator transistor

·the power driver board is malfunctioning and incorrectly sensing the bus voltage

·an incorrectly set CNC acc/dec rate

·an excessive input line voltage

·the system inertia is too high causing excessive energy to be returned to the power supply bus

·a vertical axis with insufficient counterbalancing is overdriving the servomotor and causing excessive

energy to be returned to the power supply bus

·an incorrect power supply is installed in your system. Make sure you are using a CNC power supply

SYSTEM MODULE PHASELOSS The 1394 system modulehas detecteda lossof one of theinput power phases. The

three--phase input lineis monitoredand afault will beissued whena phaseloss isdetected.

Typical causes include, oneor more input linefuses haveopened, contactor malfunction, or

incorrect wiring.

SYSTEM MODULE UNDERVOLTAGE The 1394 system modulevoltage doesnot meet the minimum operatingvoltage. The DC power

buss shallactivate theunder voltagelimit when thebus drops to275 VDC or less. It will clear at

300 Vdc. Typical causes includelow voltageon thethree phaseinput.

T

(T) WORDIN CIRCULAR MODE Anattempt was madeto activatea toollength offset in a block that generatesa circularmove.

Tool lengthoffsetscan beactivated onlyin linear blocks (or innon-motion blocksif AMP is so

configured).

T--WORD NOTALLOWED WITH M06 NEXT TOOL INT WORDwas selectedas thetool--change type in AMP whilea T--word is

programmed in an M06 block.

TAN CIRCLE NOTIN 1STBLOCK When editinga program, anattempt was madeto digitizean arcusing {CIRCLETANGNT} as

the first block in theprogram. To use this digitizing format, the control must first havea toolpath

programmed to make the arc tangent.

TEMPLATE PROGRAM NOT FOUND A transfer line quickview itemwas selectedwithout the correct part program templatepresent in

the protected directory. There are19 transfer linecycles andthere must bepart program

templates QV01thru QV19present in theprotected directory. Refer to your T-LINE-9 Quick

Start guide for details on replacing/restoring thesepart program templates.

THIRD SPINDLENOT AVAILABLE AMP configurationerror; spindle 3can beconfigured onlyon a9/290.

THIRD SPINDLENOT CONFIGURED For spindle 3 to be programmable, it must beconfigured inAMP; a decodeerror.

THRDS/IN WORDFORMAT FINERTHAN Theword format programmedis requestinga finerresolution thanthe axis word format forthe

corresponding axis allows. These word formats areset in AMP.

THREAD FEEDRATE TOO LARGE Thelead istoo largein threadingmode. Program slower spindlespeed.

THREAD LEADERROR Thethread leadwas toolarge ortoo small. This commonlyoccurs whencutting avariable

thread lead and before theend of thethreading passis reached. Either the leadgoes tozero

for adecreasing leadthread, or an axisspeed wouldexceed itsmaximum allowable cutting

feedrate when cutting an increasinglead thread.