Manual

G-codeTables

Appendix C

C-3

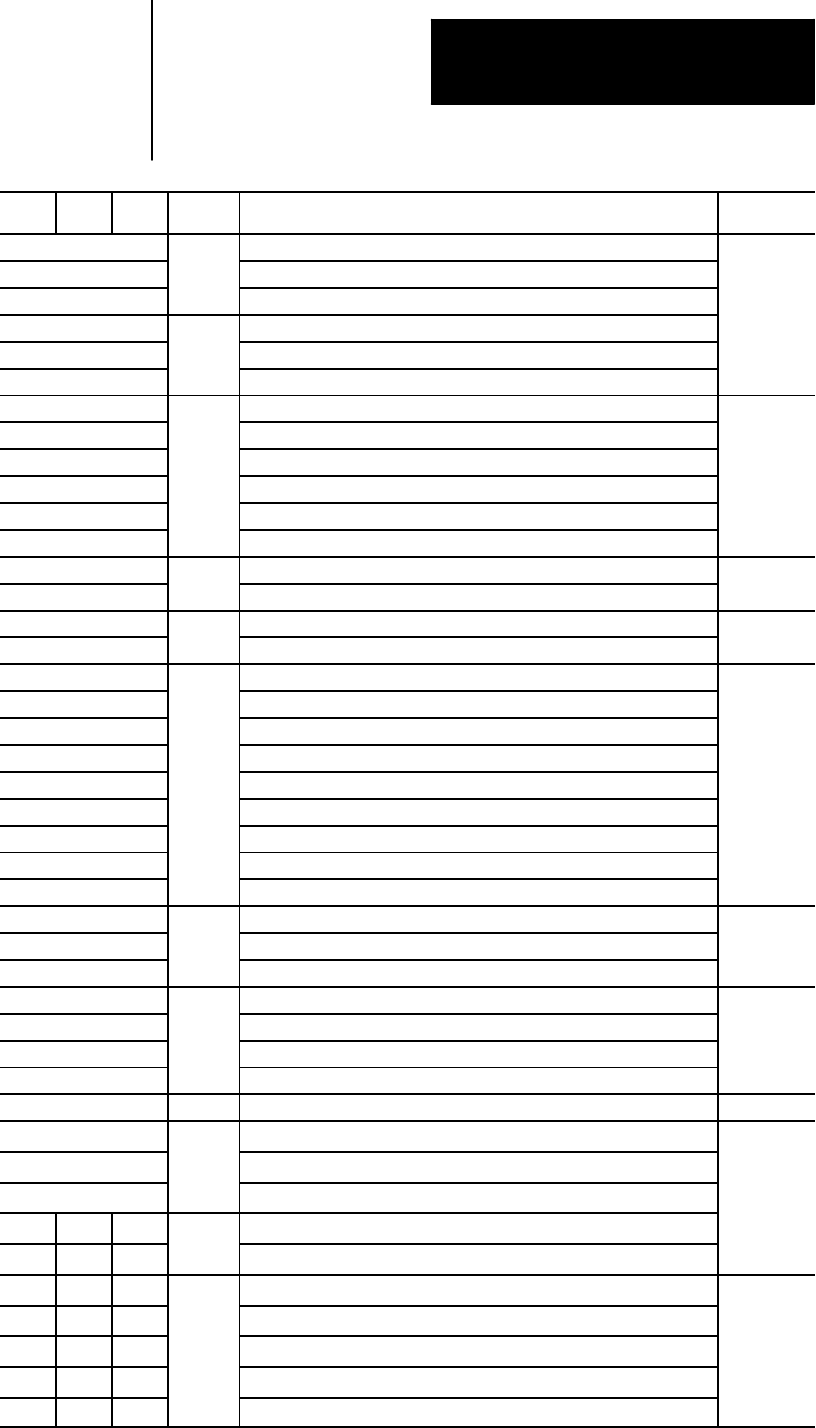

A TypeFunctionModalCB

G45 23 Disable Spindle Synchronization Modal

G46

2

3

Set Spindle Positional Synchronization

M

o

d

a

l

G46.1 Set Active Spindle Speed Synchronization

G47 24 Linear Acc/Dec in All Modes

G47.1

2

4

S--Curve Acc/Decfor Positioning andExact Stop Mode

G47.9 Infinite Acc/Dec (No Acc/Dec)(AMP--selectable only)

G48 00 Reset Acc/Dec to Default AMPedValues Non--Modal

G48.1

0

0

Acceleration Ramp for Linear Acc/DecMode

N

o

n

-

-

M

o

d

a

l

G48.2 Deceleration Ramp for Linear Acc/DecMode

G48.3 Acceceleration Ramp for S--Curve Acc/DecMode

G48.4 Dececeleration Ramp for S--Curve Acc/DecMode

G48.4 Programmable Jerk Value

G50.1 11 ProgrammableMirror Image (Cancel) Modal

G51.1 Programmable Mirror Image

M

o

d

a

l

G52 00 Offset Coordinate Zero Points Nonmodal

G53 Motionin Machine Coordinate System

G54 12 Preset Work CoordinateSystem 1 Modal

G55 Preset Work Coordinate System2

M

o

d

a

l

G56 Preset Work Coordinate System3

G57 Preset Work Coordinate System4

G58 Preset Work Coordinate System5

G59 Preset Work Coordinate System6

G59.1 Preset WorkCoordinate System 7

G59.2 Preset WorkCoordinate System 8

G59.3 Preset WorkCoordinate System 9

G60 25 Synchronous Logic/Block SynchronizationMode Modal

G60.1

2

5

Asynchronous Logic/BlockSynchronization Mode

M

o

d

a

l

G60.2 Autosynchronous Logic/BlockSynchronization Mode

G61 13 Exact Stop Mode Modal

G62 AutomaticCorner Override

G63 Tapping Mode

G64 CuttingMode

G65 00 Paramacro Call Nonmodal

G66 14 Paramacro call Modal

G66.1 Paramacro call

G67 Paramacrocall cancel

G20 G20 G70 06 Inch system selection

G21 G21 G71 Metricsystem selection

G70 G70 G72 00 O.D. and I.D. FinishingCycle Nonmodal

G71 G71 G73 O.D. andI.D. Roughing Cycle

G72 G72 G74 Roughfacing cycle

G73 G73 G75 Casting/forgingroughing cycle

G74 G74 G76 FaceGrooving Cycle