Manual

Allen-Bradley 7300 Series CNC

Tape Compatibility

Appendix D

D-4

The format for the G28 block is:

G28__D__X__Z__F

Where: Specifies:

D finalthreading depthor roughing depth. For AbsoluteProgramming mode(G90), this

parameter isprogrammed asan X axisposition. For Incremental Programming mode

(G91), this parameteris programmedas adistance measuredparallel tothe Xaxis from

the initial work surface.

X depthof first thread cuttingpass or first roughingpass. For Absolute Programming

mode, the initial depth isprogrammed asan Xaxis position. For Incremental

Programming mode, this initial depthis programmedas adistance measuredparallel to

the X axis from theinitial worksurface.

Z thedistance betweenthe startingpoint and theinfeed endpoint onthe Zaxis. Not

programming a Z or programming aZ that doesnot create anyaxis motionresults ina

plunge infeed. A plunge infeedmoves thetool directlyinto thepart with noZ component

in the move.

Programming a Z that is different thanthe startingpoint Z location generates atapered

infeed. For threads that arecut with taperedinfeed, the toolis fedinto thepart at an

angle comprised of both X and Zmotions. The angleis determinedby thelinear

intersection of the start point and the endpoint. The endpoint isdetermined bythis

parameter onZ axisand finaldepth isdetermined byD.

F feedrateof the plungeor compound infeed. The infeed rate is programmed inthe

units/inches perminute (IPM)in theinch mode, or millimeters/minute (MMPM) inthe

Metric mode.

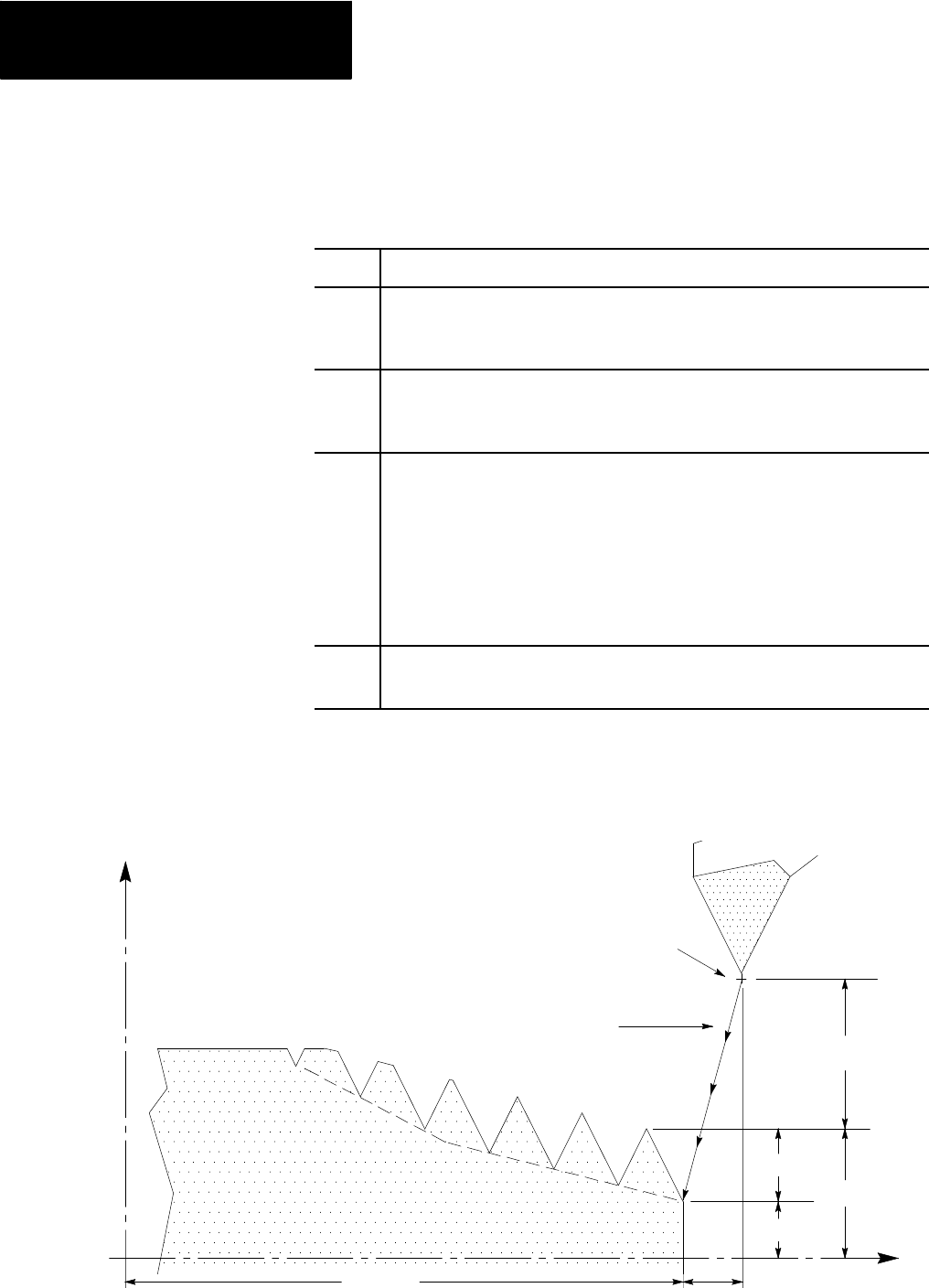

Figure D.1 illustrates these parameters.

Figure D.1

G28 Multi-pass Thread Cutting Parameters

(Absolute/Incremental Programming Mode)

X

Z

X abs.

D abs.

X inc.

Z

a

b

s

.

Z inc.

D inc.

Starting point

1st pass

2nd pass

3rd pass

Tapered infeed