Instruction Manual

Table Of Contents

- S-3056-1 Distributed Power System SA3100 Drive Configuration and Programming Instruction Manual

- Important User Information

- Contents

- List of Figures

- List of Tables

- Chapter 1 Introduction

- Chapter 2 Configuring the UDC Module, Regulator Type, and Parameters

- 2.1 Adding a Universal Drive Controller (UDC) Module

- 2.2 Entering the Drive Parameters

- 2.3 Configuring the Vector with Constant Power Regulator

- 2.4 Configuring the Volts per Hertz (V/Hz) Regulator

- 2.5 Configuring Flex I/O

- 2.6 Generating Drive Parameter Files and Printing Drive Parameters

- Chapter 3 Configuring the UDC Module’s Registers

- 3.1 Register and Bit Reference Conventions Used in this Manual

- 3.2 Flex I/O Port Registers (Registers 0-23)

- 3.3 UDC/PMI Communication Status Registers (Registers 80-89/1080-1089)

- 3.4 Command Registers (Registers 100-199/1100-1199)

- 3.5 Feedback Registers (Registers 200-299/1200-1299)

- 3.6 Application Registers (Registers 300-599, Every Scan) (Registers 1300-1599, Every Nth Scan)

- 3.7 UDC Module Test I/O Registers (Registers 1000-1017)

- 3.8 Interrupt Status and Control Registers (Registers 2000-2047)

- Chapter 4 Application Programming for DPS Drive Control

- Chapter 5 On-Line Operation

- Appendix A SA3100 Vector Regulator Register Reference

- Appendix B SA3100 Volts / Hertz Regulator Register Reference

- Appendix C SA3100 Local Tunable Variables

- Appendix D Vector with Constant Power Regulator

- Appendix E Volts per Hertz (V/Hz) Regulator

- Appendix F Status of Data in the AutoMax Rack After a STOP_ALL Command or STOP_ALL Fault

- Appendix G Torque Overload Ratio Parameter Precautions

- Appendix H Default Carrier Frequency and Carrier Frequency Limit for Drive Horsepower Ranges

- Appendix I Vector with Constant Power Parameter Entry Example

- Index

J-6 Drive Configuration and Programming

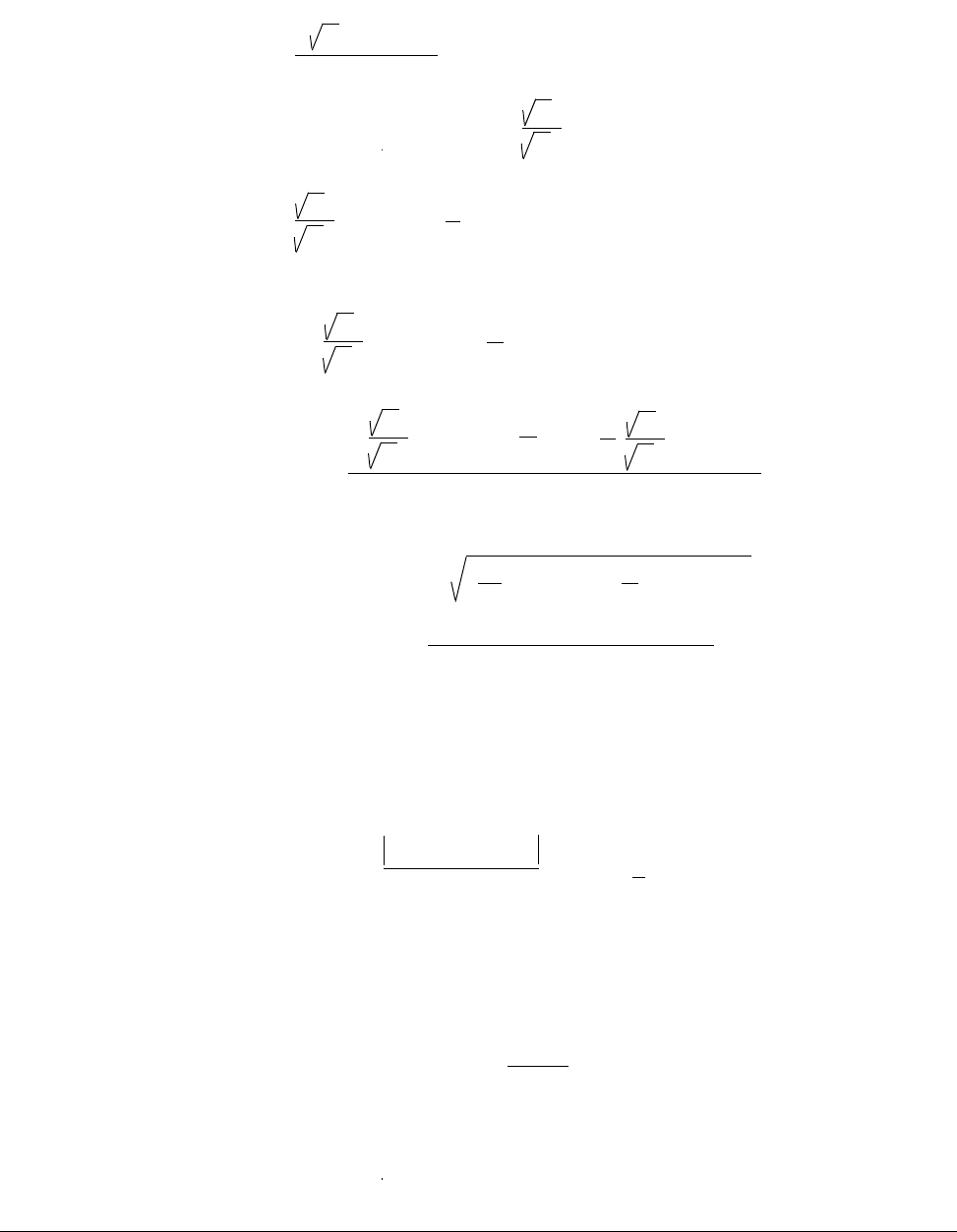

4. Calculate the remainder of the necessary motor parameters using the following

measurements:

5. Run the full algorithm with the parameters calculated above with flux loop and

access the table starting with the first point. The first point is the rated d-

component current I

d_rtd

. The value of this current must satisfy the following

inequality:

6. If the inequality in #17 is true, then continue to access the table. If the inequality

(17) is not true then recalculate all the motor parameters with new I

d_rtd

and

rerun.

System architecture allows only three parameters to be saved.

L

s0

=

2 V

NL_rtd

V

2

mot _ rtd

(stator inductance)

( 10 )

I

d_rtd_1

(q - component voltage) ( 11 )

V

q_rtd

= OLR

.

I

q _ rtd _ 1

R

st _1

+

2

.

π

.

f

0

( 12 )

R

st_1

OLR

.

I

q _ rtd

_

1

V

d_rtd

_ 1

( 16 )

=

=

( 14 )

.

.

.

2

3

.

V

NL _ rtd

q - component voltage has to satisfy the following inequality:

2

3

.

V

mot _ rtd

V

q _ rtd

> 2

If the above inequality (12) is true then V

q_rtd

can be used for further calculations.

If the expression (12) is not true then the following assumption has to be set:

( 15 )

2

3

V

mot _ rtd

V

mot _ rtd

V

q_rtd

=

V

NL _ rtd

.

( 13 )2.5

and stator resistance has to be recalculated using the follow equation:

2

3

(

)

2

3

2.5

.

Then d-component voltage and modified leakage inductance can be calculated:

2

3

.

V

2

q _ rtd _ 1

L*

σs 0

=

V

d _ rtd _ 1

+ I

d _ rtd _ 1

.

R

st _ 1

2

.

π

.

f

0

OLR

.

I

q _ rtd

_

1

.

( 17 )

I

d_rtd -

I

d _ rtd _ 1

I

d _ rtd

.

100% < 2%

( 18 )

● stator time constant:

T

st

=

L*

σs 0

R

st _ rtd

● stator resistor:

R

st _ rtd

● magnetizing current:

I

z _ rtd