Instruction Manual

Table Of Contents

- S-3056-1 Distributed Power System SA3100 Drive Configuration and Programming Instruction Manual

- Important User Information

- Contents

- List of Figures

- List of Tables

- Chapter 1 Introduction

- Chapter 2 Configuring the UDC Module, Regulator Type, and Parameters

- 2.1 Adding a Universal Drive Controller (UDC) Module

- 2.2 Entering the Drive Parameters

- 2.3 Configuring the Vector with Constant Power Regulator

- 2.4 Configuring the Volts per Hertz (V/Hz) Regulator

- 2.5 Configuring Flex I/O

- 2.6 Generating Drive Parameter Files and Printing Drive Parameters

- Chapter 3 Configuring the UDC Module’s Registers

- 3.1 Register and Bit Reference Conventions Used in this Manual

- 3.2 Flex I/O Port Registers (Registers 0-23)

- 3.3 UDC/PMI Communication Status Registers (Registers 80-89/1080-1089)

- 3.4 Command Registers (Registers 100-199/1100-1199)

- 3.5 Feedback Registers (Registers 200-299/1200-1299)

- 3.6 Application Registers (Registers 300-599, Every Scan) (Registers 1300-1599, Every Nth Scan)

- 3.7 UDC Module Test I/O Registers (Registers 1000-1017)

- 3.8 Interrupt Status and Control Registers (Registers 2000-2047)

- Chapter 4 Application Programming for DPS Drive Control

- Chapter 5 On-Line Operation

- Appendix A SA3100 Vector Regulator Register Reference

- Appendix B SA3100 Volts / Hertz Regulator Register Reference

- Appendix C SA3100 Local Tunable Variables

- Appendix D Vector with Constant Power Regulator

- Appendix E Volts per Hertz (V/Hz) Regulator

- Appendix F Status of Data in the AutoMax Rack After a STOP_ALL Command or STOP_ALL Fault

- Appendix G Torque Overload Ratio Parameter Precautions

- Appendix H Default Carrier Frequency and Carrier Frequency Limit for Drive Horsepower Ranges

- Appendix I Vector with Constant Power Parameter Entry Example

- Index

3-48

SA3100 Drive Configuration and Programming

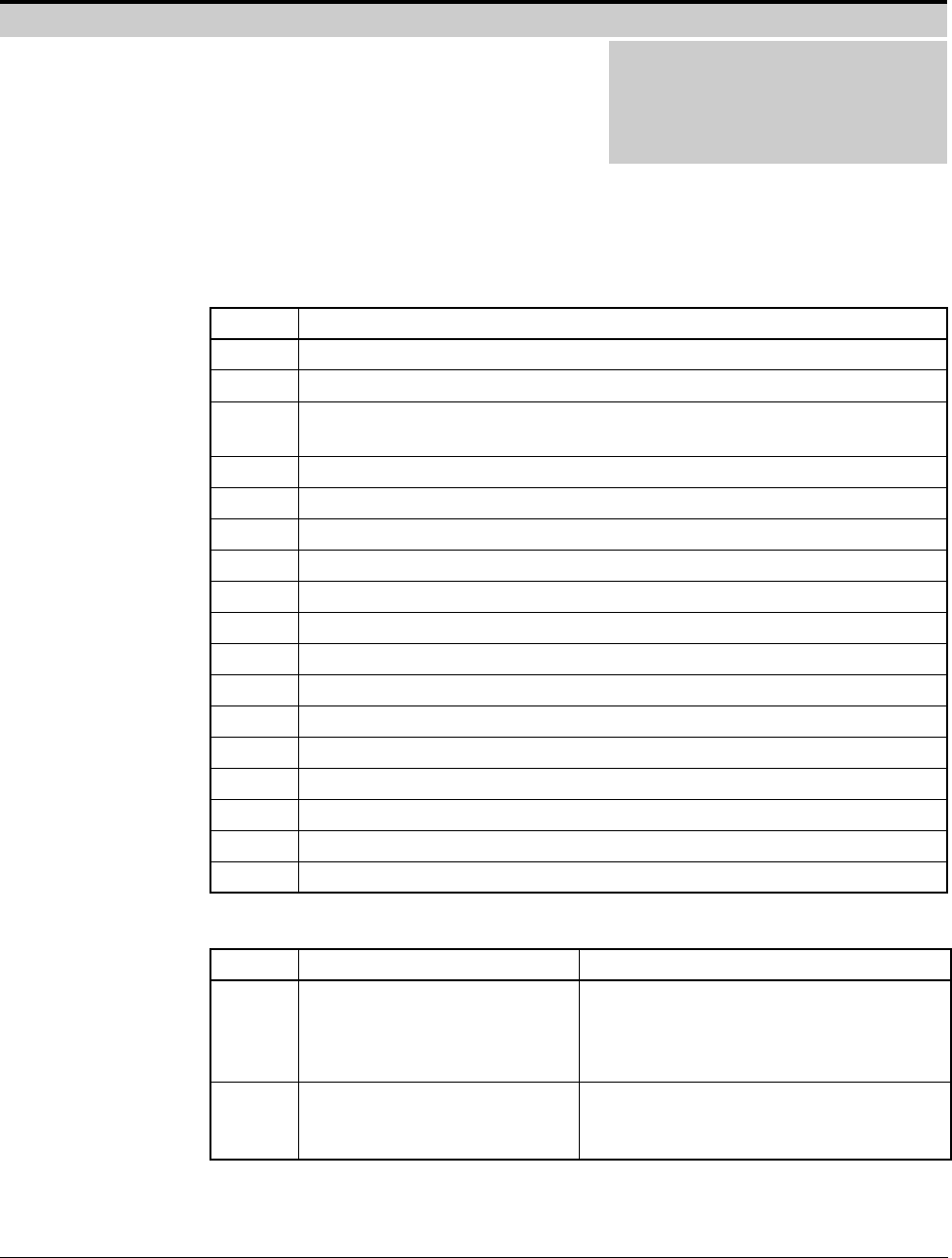

AC Power Technology Calibration and Power-Up Faults:

If any of the following calibration and power-up diagnostic faults occurs, replace the

PMI Regulator motherboard. These faults indicate a hardware failure of the AC power

technology circuit on the motherboard. Register 202, bit 11 (FLT_PTM@) will be set.

Run Time AC Power Technology Hardware Faults:

Diagnostic Fault Code Register 222/1222

The Diagnostic Fault Code register displays an error code to help

diagnose the cause of a problem reported in other registers.

Note that this register is available for monitoring only. It cannot be

referenced in an application task.

Sug. Var. Name: DIAG_FLT%

Units: N/A

Range: N/A

Access: Read only

Code Fault

1 D/A high voltage error (+3.3V 10% out of tolerance)

2 D/A low voltage error (-3.3V 10% out of tolerance)

3 Torque current loop proportional gain not within calibration limits

(14<g<30)

4 Flux current loop proportional gain not within calibration limits (14<g<30)

5 Flux current loop integrator time constant not within calibrated limits

6 Torque current loop integrator time constant not within calibrated limits

7 Modulation index error

8 Harmonic DAC limit error

9 Modulation range error

10 Harmonic DAC range error

11 Programmable current limit or the ground fault limit fault

12 Voltage feedback integrator error

13 A/D converter interrupt error

14 Pulse Width Modulator frequency error

15 DC bus current not zero at power-up.

16 Phase U current not zero at power-up.

17 Phase W current not zero at power-up.

Code Fault Description/Action

20 Power supply monitor trip AC power technology power supply level

out of tolerance. Replace the PMI

Regulator motherboard and/or power

supply.

21 AC power technology

watchdog time-out

AC power technology circuit watchdog

timer expired. Replace the PMI

Regulator motherboard.