TrustedTM PD-T8013 TrustedTM SOE and Process Historian Package Introduction The Sequence of Events (SOE) Collection program generates a time-stamped log of all faults, field trips, output actions etc. recorded by the 8000 Series System. The Process Historian (PH) program provides the user with the facility to log and record analogue variables. Both programs are supplied on a single disk, part No. T8013.

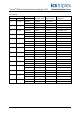

TrustedTM SOE and Process Historian Package T8013 Issue Record Issue Number Date Revised by Technical Check Authorised by 10 Dec 04 N Owens G Creech R Cockman 11 Sep 05 J W Clark 12 Aug 06 N Owens I Vince P Stock Compilation, use 13 Dec 06 N Owens I Vince P Stock Corrections 14 Sep 07 N Owens I Vince P Stock Comms setup 15 Nov 07 N Owens A Holgate P Stock SOE initial states 16 April 10 S.

TrustedTM SOE and Process Historian Package T8013 This page is intentionally blank Issue 16 April 2010 PD-T8013 3

TrustedTM SOE and Process Historian Package T8013 Table of Contents 1. Installation ................................................................................................................................. 8 2. Startup ....................................................................................................................................... 9 3. Collecting SOE Data ............................................................................................................... 10 3.

TrustedTM SOE and Process Historian Package T8013 Figures Figure 1 Fresh Installation Screen............................................................................................................8 Figure 2 Initial Display...............................................................................................................................9 Figure 3 Launcher Window.......................................................................................................................

TrustedTM SOE and Process Historian Package T8013 Notice The content of this document is confidential to ICS Triplex Technology Ltd. companies and their partners. It may not be given away, lent, resold, hired out or made available to a third party for any purpose without the written consent of ICS Triplex Technology Ltd. This document contains proprietary information that is protected by copyright. All rights are reserved.

TrustedTM SOE and Process Historian Package T8013 Revision and Updating Policy All new and revised information pertinent to this document shall be issued by ICS Triplex Technology Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The change is to be recorded on the Amendment Record of this document.

TrustedTM SOE and Process Historian Package T8013 1. Installation Insert the 8013 CD into the computer CD drive. If Autorun is enabled, the InstallShield wizard runs and prepares files for installation. Click Next on the introductory screen and read and accept the license agreement. The next screen allows entry of a user and company name, and chooses to install the icons in ‘All Users’ or your local profile. Three choices are available, as shown in Figure 1.

TrustedTM SOE and Process Historian Package T8013 2. Startup Connect the Engineering Workstation to the TMR Communications Interface using the Communication Cable TC-304-01-Xm0. Double clicking the ‘SOE and Process Historian’ application icon at the Engineering Workstation will initiate the screen display shown in Figure 2. Figure 2 Initial Display After a few seconds, the screen display shown above will be replaced with the SOE/PH ‘launcher’ window shown in Figure 3.

TrustedTM SOE and Process Historian Package T8013 3. Collecting SOE Data As previously stated, pressing the ‘SOE Collector’ button will initiate the SOE display shown in Figure 4. Figure 4 SOE Collector To start collecting SOE data, the user must first implement a number of actions as detailed below: 1. Configure the SOE communications port. 2. Select the appropriate SOE symbol file 3. Select the SOE target ID 4. Select the sort mode (time or tag) 5. Select the SOE log file 6.

TrustedTM SOE and Process Historian Package T8013 3.1. SOE Communications Port Configuration TM The ports on the Trusted TMR Communications Interface module may be configured to allow SOE data collection using serial comms or via the Ethernet. The required method is chosen by first selecting the ‘Configure Port’ option from the ‘File’ menu. Selecting serial ports COM 1 and 2 enable the selection of Baud rate and parity.

TrustedTM SOE and Process Historian Package T8013 3.2. SOE Symbol File Selection Tag, true/false state information and description text is retrieved from database files produced by the TM IEC1131 TOOLSET as part of the program creation/compilation process. The Trusted system only contains memory run-time addresses and state information. The file that contains the bulk of the information is called ‘Appli.tst’ and is found in the same directory as the user’s application.

TrustedTM SOE and Process Historian Package T8013 3.6. SOE Collection Mode The Communications Interface has a large buffer of events. It is possible to gather this buffer first until the collector has caught up with current events, but this can take a long time. Therefore there is an option under the Mode menu for choosing how much of this buffer is collected.

TrustedTM SOE and Process Historian Package T8013 3.8. Additional SOE Features Additional features of SOE include the following: 1. Copy to Clipboard 2. Print 3. Save To File 3.8.1. Copy To Clipboard It is possible to copy the contents of the current display to the Windows clipboard for pasting into other applications. This is achieved by using the ‘Copy To Clipboard’ option from the ‘File’ menu. The text copied may then be pasted into other Windows applications, e.g. Excel. 3.8.2.

TrustedTM SOE and Process Historian Package T8013 Different colours may be used for the display point status. This is achieved by appending a colour specifier to the True/False strings declared for the point in the IEC1131 TOOLSET dictionary. For example, to make ‘TRUE’ appear in green, the true text would be set to ‘TRUE_g’ where ‘_g’ is the specifier for green. Colour specifiers available to the user are detailed in Table 1 below.

TrustedTM SOE and Process Historian Package T8013 3.10. Assigning variables for SOE The SOE collector provides the user with two options. The user may tag changes for a Boolean variable which only has two states. However, the collector will also allow the user to add “Channel state” changes. These channel state changes are described in the ANALOGUE SOE VARIABLES paragraph. Note: All SOE variables must either be defined as INPUT or OUTPUT.

TrustedTM SOE and Process Historian Package T8013 Figure 8 Boolean Extended Attributes The user should enable the Boolean I/O Enable SOE logging option to provide the variable with SOE attributes. The user must select the OK button, then select OK to exit the next window. This variable must be attached to an I/O board within the application program for the System. To select the appropriate board to which the variable is to be attached, the user must determine the module and channel driving the output.

TrustedTM SOE and Process Historian Package T8013 3.10.2. Intermediate SOE Variables To select intermediate variables for collection by the SOE, the user must first declare an soe board from the board library within the IEC1131 TOOLSET I/O connection. Double click on a free number in the I/O Connection. Select boards, find soe and select OK. This will enter an soe board in the I/O Connection table as shown in Figure 10 below.

TrustedTM SOE and Process Historian Package T8013 3.10.3. Analogue SOE Variables TM The Trusted SOE collector also allows the user to enter analogue variables to the SOE log. This will allow the user to attach a channel state to an SOE tag. To do this the user must create the variable within the IEC1131 TOOLSET Data Dictionary. Creating or selecting this variable will initiate the dialogue box shown in Figure 12 below.

TrustedTM SOE and Process Historian Package T8013 Unlike a Boolean SOE variable which may be attached to any I/O board within the application program, an analogue SOE variable must be attached to the STATE rack of a High Integrity I/O board as defined in the application program and shown in Figure 14 below. Figure 14 STATE I/O Connection board Double clicking the mouse on the selected channel will provide the user with a list of unattached variables as shown in Figure 15 below.

TrustedTM SOE and Process Historian Package T8013 4. Collecting Process Historian (PH) Data Pressing the ‘Process Historian’ button in Figure 3 will initiate the PH display shown in Figure 16 below. Figure 16 Process Historian Collector To start collecting PH data, the user must first implement a number of actions as detailed below: 1. Configure the PH communications port. 2. Select the appropriate PH symbol file 3. Select the PH target ID 4. Select the PH log file 5.

TrustedTM SOE and Process Historian Package T8013 4.2. PH Communications Port Configuration TM The ports on the Trusted TMR Communications Interface module may be configured to allow SOE data collection using serial comms or via the Ethernet. The required method is chosen by first selecting the ‘Configure Port’ option from the ‘File’ menu. Selecting serial ports COM 1 and 2 enable the selection of Baud rate and parity.

TrustedTM SOE and Process Historian Package T8013 In the PH Collector, the Target ID is selected using the ‘Set ID’ option, which may be found in the ‘Target’ menu. 4.5. PH Log File Selection All PH entries may optionally be logged to a log file held on the user’s Engineering Workstation. To enable a log file, the user must select the ‘Log File’ option which may be found in the ‘Logging Menu’. Entries are appended to the end of the file as they are collected. 4.6.

TrustedTM SOE and Process Historian Package T8013 4.8. PH Example Display An example of a PH display is shown in Figure 18 below. Figure 18 PH Data Display The example shown displays a single channel from the set of all analogue channels available. Note: The list box at the right of the display provides the names of the available tags.

TrustedTM SOE and Process Historian Package T8013 4.9. Assigning variables for PH Process Historian deals with analogue tags only and is intended to compliment SOE. Tags must have the suffix ‘_PH’ at the end of the tagname and must be connected to a prochist board. A Modbus address is not necessary. 4.9.1. PH Connection To configure a tag for connection to Process Historian it should be configured as an output. Figure 19 shows a tag created to connect to a prochist board. The tag may be a real or integer.

TrustedTM SOE and Process Historian Package T8013 Once defined, the user enables process historian logging by attaching the variable created above to a channel on this board. Double click on the appropriate channel of the prochist board. This will display all the unconnected output variables available for PH collection as shown in Figure 21 below. Figure 21 SOE Board Connection The variable may now be attached to this channel by selecting the Connect button or by double clicking on the tagname.

TrustedTM SOE and Process Historian Package T8013 5. SOE and Initial States The following should be noted when using SOE data collection by any method. • ‘Native’ output modules (P8451,61,71 etc.) never record the initial state of an output as an SOE event. • Non-native output modules (e.g. Regent modules) record an initial state of TRUE as an SOE event. • All inputs supporting SOE will always record an event if the initial input state is TRUE.