Specifications

September 2012 Page

22

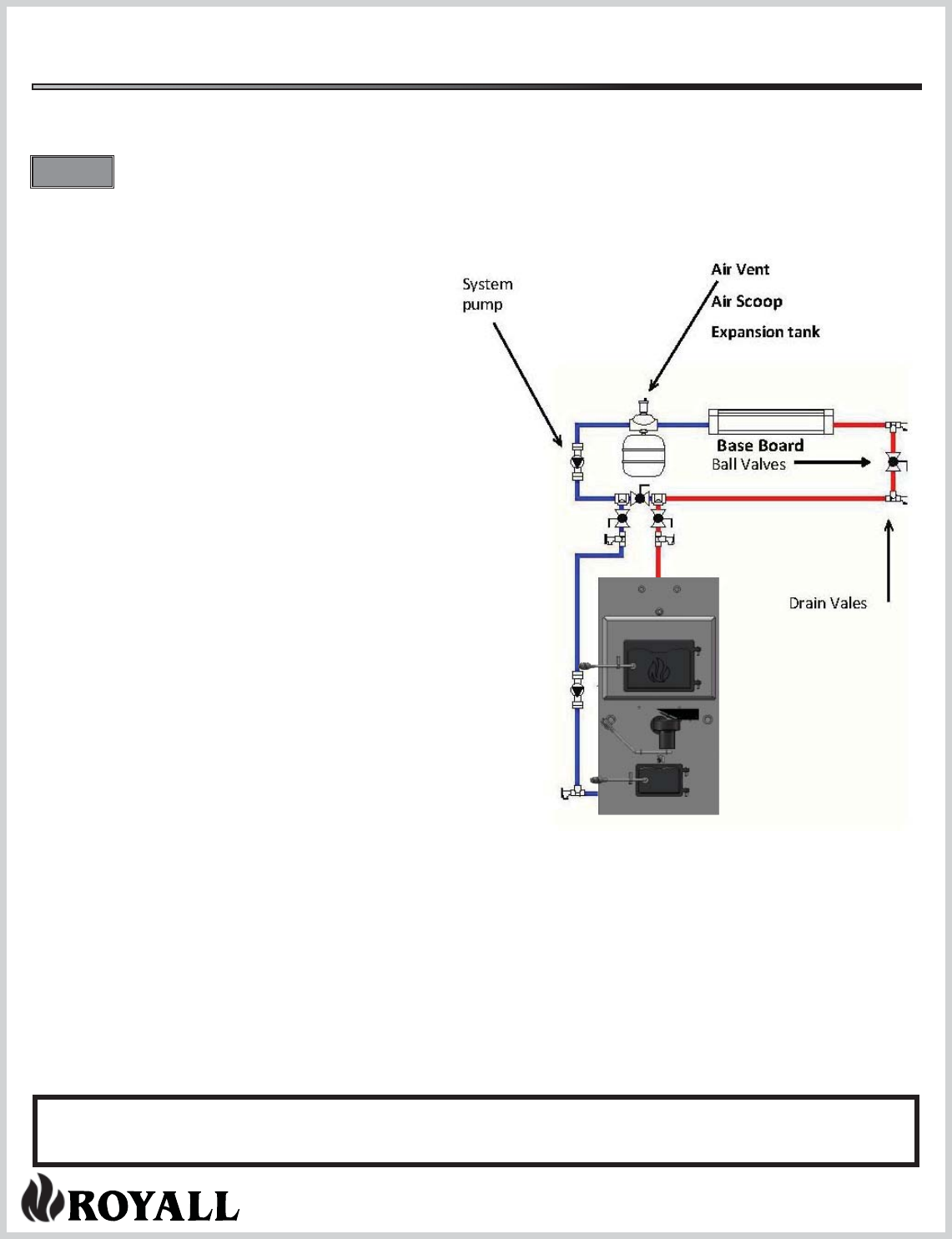

INSTALLATION: GENERIC SYSTEMS

The system Diagrams provided are only suggested schematics for generic systems and do not

purport to show all required components necessary to meet all required codes. Complex

systems should be designed by a professional heating system.

SYSTEM PLUMBING

CAUTION

GENERAL COMMENTS

PIPING AT THE APPLIANCE

Base Board

The piping at the appliance does not change with most

applications In the applications drawings on following

pages it is not shown but is assumed to be as shown on

this page.

PUMPS

Is recommended that a system pump be installed to en-

sure ow through the boiler at all times. If the system is

designed for continuous ow, then a system pump is not

necessary. All pumps must be sized properly based on

ow requiems.

EXPANSION TANK

Hydronic heating systems require an expansion tank to

allow water to expand/contract as it heats or cools

without adversely a ecting system pressure. A diaphragm

type expansion tank is recommended. The tank must be

installed vertically. Typically it is attached to the bottom of

an air scoop. An existing hydronic system should already

have an expansion tank. Though it is not necessary to add

another expansion tank, ensure that the existing tank is

large enough to handle both the volume of the solid fuel

boiler and the volume of the existing system.

AIR ELIMINATION

Air will collect at the high points in the system, potentially

interrupting ow. An air vent should be located at points to

allow the system to be purged of air.

COMPLEX SYSTEMS SHOULD BE DESIGNED BY A HEATING PROFESSIONAL