Installation Guide

507052-04 Page 9 of 53Issue 1727

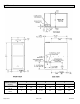

Figure 7. Equipment in Conned Space - All Air from

Outside

(All Air Through Ventilated Attic)

Figure 8. Equipment in Conned Space - All Air from

Outside

If this unit is being installed in an application with

combustion air coming in from a space serviced by an

exhaust fan, power exhaust fan, or other device which

may create a negative pressure in the space, take care

when sizing the inlet air opening. The inlet air opening

must be sized to accommodate the maximum volume

of exhaust air as well as the maximum volume of

combustion air required for all gas appliances serviced

by this space.

WARNING

Ventilation Louvers

Inlet Air

(Minimum 12 in.

(305mm) above

Attic Floor)

Roof Terminated

Exhaust Pipe

Furnace

*Intake Debris

Screen

(Provided)

* See Maximum Vent Lengths table

NOTE: The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour of the total input of all equipment in the

enclosure.

Figure 9. Equipment in Conned Space

(Inlet Air from Ventilated Attic and Outlet Air to

Outside)

Roof Terminated

Exhaust Pipe

Furnace

Ventilation

Louvers

(Crawl Space)

*Intake Debris Screen Provided

Inlet Air

Minimum

12 in. (305mm)

above Crawl

Space Floor

Coupling or

3 in. to 2 in.

Transition

(Field Provided)

* See Maximum Vent Lengths table

NOTE: The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per hour of the total input of all equipment in the

enclosure.

Figure 10. Equipment in Conned Space

(Inlet Air from Ventilated Crawl Space and Outlet Air

to Outside)