Product Manual A

WARNING! u NEVER USE NAILS OR UNSPECIFIED FASTENERS

u FASTENER SPECIFICATIONS u

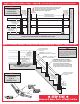

To Anchor the Safety Boot - Different Types of Subfloor Material Require Different

Types of Fasteners In Order to Exceed the 200 lb. OSHA Guardrail Requirement

FASTENER SPECIFICATIONS FOR VARIOUS TYPES OF SUBFLOOR MATERIAL APPLICATIONS

Use the Supplied Drill Adapter with a Power Drill and Socket for Fast and Easy Installation

SOLID 2X WOOD APPLICATIONS

for solid wood applications use:

u 4 - Hex-Head Lag Screws, ⅜ X 2 inch

and;

u 4 - ⅜ X 1-½ Inch Fender Washers

(Fender Washers supplied with all orders)

u Anchor directly into solid 2X lumber using the four

primary corner holes.

STURD-I-FLOOR

®

(1-⅛ INCH THICK) PLYWOOD

for Sturd-I-Floor

®

(1-⅛ inch thick) plywood applications use:

u 5 - Hex-Head Lag Screws, ⅜ X 2 inch

and;

u 5 - ⅜ X 1-½ Inch Fender Washers

(Fender Washers supplied with all orders)

u Anchor directly into Sturd-I-Floor

®

(1-⅛ inch thick)

plywood using the four primary corner holes and by

adding a 5th screw on the inside of the guardrail or

stair rail system in the secondary hole provided.

PLYWOOD (LESS THAN 1-⅛ INCH THICK)

OR OSB APPLICATIONS

for plywood (less than 1-⅛ inch thick) or OSB applications use:

u 4 - Hex-Head Lag Screws, ⅜ X 3 inch

and;

u 4 - ⅜ X 1-½ Inch Fender Washers

(Fender Washers supplied with all orders)

u Anchor through the plywood or OSB into floor joists or

solid 2X lumber blocking on the underside of subfloor

using the four primary corner holes.

CONCRETE APPLICATIONS

for concrete applications use:

u 4 - Common Masonry Fasteners or Similar Concrete

Anchors and;

u 4 - ⅜ X 1-½ Inch Fender Washers

(Fender Washers supplied with all orders)

u Anchor using the four primary corner holes.

IMPORTANT: Due to the variances in concrete mixtures and applications (such

as, concrete mixture type, psi strength, slab thickness, cure time, etc.), concrete

fasteners used to secure the Safety Boot MUST be evaluated on a case by case

basis by a qualified competent person. They should verify that the selected fastener

specifications for average ultimate pullout and shear values are in compliance with

the OSHA required strength standards.* Most concrete fasteners are packaged to

include a product specification chart that denotes the average ultimate pullout and

shear values in concrete and/or hollow block applications.

* OSHA STANDARD 1926.502(b)(3):

Guardrail systems shall be capable of withstanding, without failure, a force of at

least 200 pounds (890 N) applied within 2 inches (5.1 cm) of the top edge, in any

outward or downward direction, at any point along the top edge.

FOR OTHER SUBFLOORING APPLICATIONS

Always verify through a professional engineer that the subflooring

material as well as the fasteners used to secure the Safety Boot will

support the required load as needed for your specific applications.