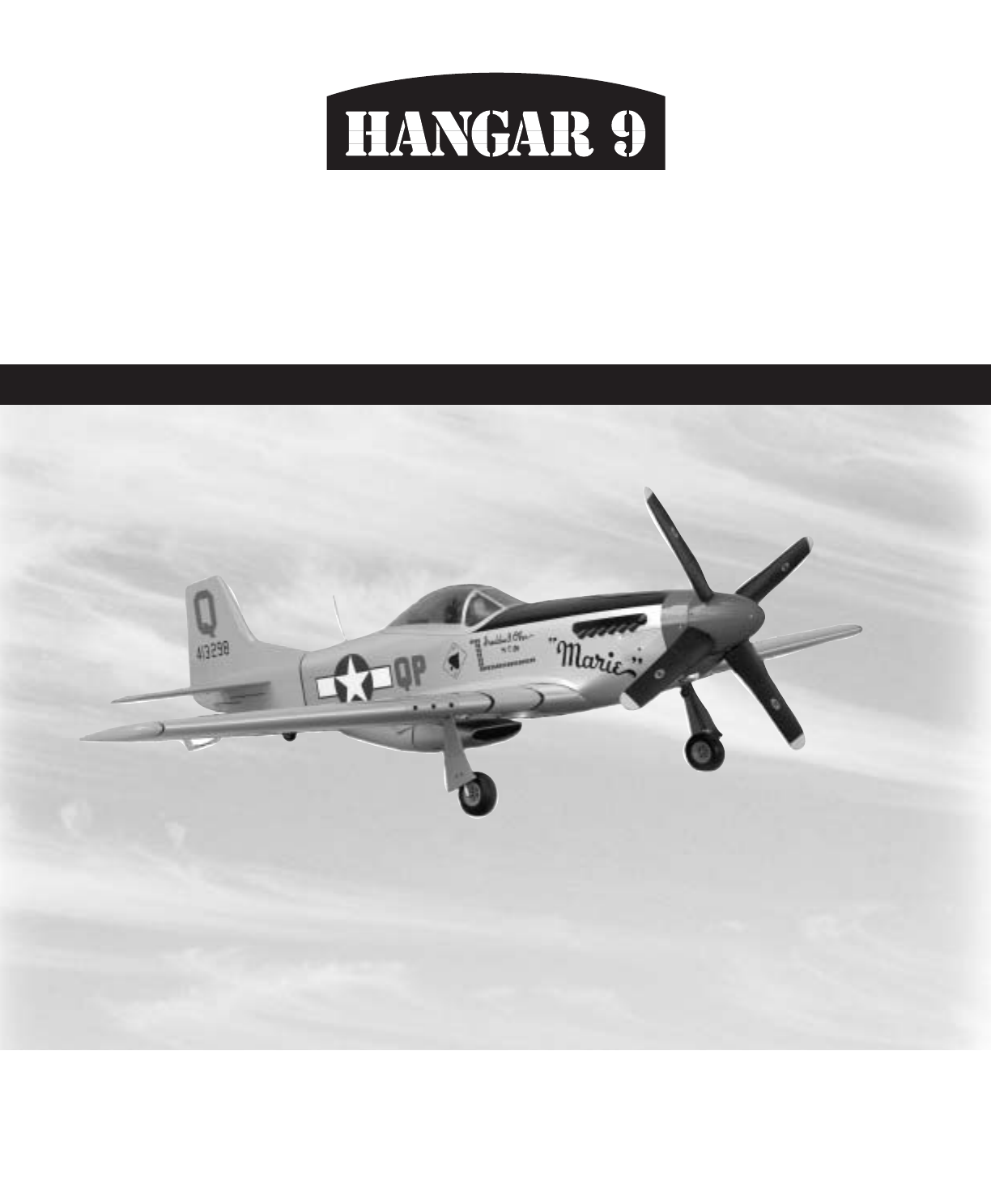

® TM WE GET PEOPLE FLYING P-51 Mustang 1.50 ARF ASSEMBLY MANUAL Specifications Wingspan: .............. Length: .................... Wing Area:............. Weight: ................... Engine:..................... Radio: ...................... 77 in (1956mm) 68 in (1727mm) 1039 sq in (67.03sq dm) 13–14 lb (5.89–6.34 kg) 1.20–2.00 4-stroke 6-channel w/10 servos Congratulations on your purchase of the Hangar 9® P-51 Mustang ARF.

Table of Contents Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Additional Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Contents of Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Additional Required Tools and Adhesives . . . . . . . . . . . . . .

Contents of Kit B F C E Large Parts A. HAN2401 B. HAN2404 C. HAN2402 D. HAN2405 E. HAN2406 F. HAN2407 Wing Set with Joiner Fuselage Tail Set Fiberglass Belly Scoop Fiberglass Cowl Canopy Small Parts 1. HAN2403 2. HAN2409 3. HAN2410 4.

Additional Required Tools and Adhesives Tools • Drill • Drill Bits: 1/16", 1/8", 3/32", 5/64”, 5/32" • Phillips screwdriver (small, medium) • Pliers • Side Cutters • Moto-tool w/cut-off wheel • Hobby knife with #11 blade • 90-degree triangle • Straight edge • Canopy scissors • Side cutters • Adjustable wrench • Hex wrench Other Required Items • Mixing sticks for epoxy • Epoxy brushes • Rubbing alcohol • Sanding bar • Sandpaper (medium) • Paper towels • Wax paper • Felt-tipped pen or pencil • Measuring devi

Before Starting Assembly Before beginning the assembly of your P-51, remove each part from its bag for inspection. Closely inspect the fuselage, wing panels, rudder, and stabilizer for damage. If you find any damaged or missing parts, contact the place of purchase. If you find any wrinkles in the covering, use a heat gun or covering iron to remove them. Use caution while working around areas where the colors overlap to prevent separating the colors.

Section 1: Hinging the Ailerons Required Parts • Right and left wing panels w/ailerons • CA hinges (6) Required Tools and Adhesives • Thin CA glue • CA remover/debonder • Paper towel • T-Pins Step 3 Slide the aileron onto the wing until there is only a slight gap between the aileron and wing panel. Remove the T-pins and snug the aileron against the wing panel. Slide the aileron towards the wing tip until there is only a 1/32" gap between the end of the aileron and wing tip.

Section 1: Hinging the Ailerons Step 5 Turn the wing panel over, deflect the aileron in the opposite direction and apply thin CA to the other side of the hinges as described in the previous step. Make sure the thin CA penetrates completely into both the aileron and wing panel. Step 7 Firmly grasp the wing and aileron and gently pull on the aileron to ensure the hinges are secure and cannot be pulled apart. Use caution when gripping the wing and aileron to avoid crushing the structure.

Section 2: Aileron Servo Installation Required Parts • Wing assembly • Aileron servos w/mounting hardware (2) • Servo hatch screws (#2 x 3/8") (4) • Large Servo Arm (JRPA212) (1 pkg) • Servo mounting blocks (4) • 24" Servo Lead Extension (JRPA102) • Aileron servo hatch (2) Step 2 Install the recommended servo hardware (grommets and eyelets) supplied with the servo.

Section 2: Aileron Servo Installation Step 4 Place the aileron servo between the mounting blocks and use a felt-tipped pen to mark the location of the four servo mounting screws. Note that the servo must not touch the hatch in order to isolate engine vibration. Note: Before mounting the servo, it is suggested to electronically center the servo using the transmitter, then install the servo arm to avoid having to remove the servo and center the arm later.

Section 2: Aileron Servo Installation Step 7 Use a piece of string with a small weight (such as a wheel collar) attached as a device to pull the servo lead through the wing. Lower the weight through the opening at the root of the wing as shown. Photo for Step 9 Step 8 Stand the wing on the tip and allow the weight to drop through the wing until it appears in the opening for the servo leads. It may require a little help to pass by the wing ribs in the form of slightly shaking the wing.

Section 2: Aileron Servo Installation Step 11 Remove the servo hatch cover and re-drill the holes using a 5/64" drill bit. Use 2–3 drops of thin CA to harden the underlying wood. This will prevent the screws from crushing the wood when they are tightened. Secure the hatch using four #2 x 3/8" screws. Photo for Step 11 Photo for Step 11 Step 12 Repeat Steps 1 through 11 for the remaining aileron servo.

Section 3: Aileron Linkages Required Parts • Wing assembly • Mounting screws (6) • Clevis keeper (4) • 4-40 nuts (4) • Control horn (2) • Metal clevis (4) • 4-40 x 2" threaded rod (2) • #2 x 3/8" screws (6) Step 3 Remove the back plate from the control horn using side cutters or a sharp hobby knife. Use a 5/64" drill bit to drill out the mounting holes in the control horn.

Section 3: Aileron Linkages Step 5 Drill three 1/16" holes at the locations marked in the previous step. The holes only need to be 5/16" deep; don’t drill through the top of the aileron. Step 6 Install one of the #2 x 3/8" screws into a hole drilled, then remove it. Place 2-3 drops of thin CA into the hole to harden the wood. This will eliminate the potential of the screw pulling out of the wood. Repeat this for each of the three holes. Step 7 Attach the control horn using three #2 x 3/8" screws.

Section 4: Hinging the Flaps Required Parts • Wing assembly • Nylon flap hinges (6) Required Tools and Adhesives • 30-minute epoxy • Paper towels • Rubbing alcohol • Petroleum jelly Step 1 Carefully remove the tape holding the flap to the wing. Locate the hardwood control horn mount in the flap. The center of the mount is located 5" from the root of the flap (wide end). The plate is 1 1/4" wide and 1" deep. Step 2 Locate three of the nylon flap hinges.

Section 4: Hinging the Flaps Step 4 Install the hinges in the flap and slide the flap into position. Check to make sure the flap aligns with both the aileron and wing trailing edge. If it does not, enlarge the first 1/4" of the hinge holes in both the wing and flap to provide more clearance for the center of the hinge. This will allow the flap to be positioned closer to the wing for alignment. Step 5 Use 30-minute epoxy to install the hinges.

Section 5: Flap Servo Installation Required Parts • Wing assembly • Flap servos w/mounting hardware (2) • Servo hatch screws (#2 x 3/8") (4) • Large Servo Arm (JRPA212) (1 pkg) • Servo mounting blocks (4) • 6" Servo Lead Extension (JRPA094) • Flap servo hatch (2) Required Tools and Adhesives • Thin CA • Thick CA • Phillips screwdriver • Felt-tipped pen • Drill Bit: 1/16", 5/64" • Drill • String/.dental floss Step 1 Locate the flap hatch.

Section 5: Flap Servo Installation Step 3 Locate the servo mounting blocks. Use 6-minute epoxyto glue them in place on the marks made in the previous step. Let the epoxy fully cure before proceeding to the next step. Step 4 Place the flap servo between the mounting blocks and use a felt-tipped pen to mark the location of the four mounting screws. Note: The servo must not touch the hatch in order to isolate engine vibration.

Section 5: Flap Servo Installation Step 7 Connect a 6" Servo Lead extension (JRPA094) to the servo lead. Secure the connectors by tying them in a knot using dental floss (as shown) or by using a commercially available connector clamp to prevent the servo leads from becoming disconnected. Note: It is always a good idea to secure the servo connector and servo extension together to prevent the wires from becoming unplugged inside the wing.

Section 5: Flap Servo Installation Step 11 Place the hatch cover into position in the flap opening. Measure in 1/8" on all four sides of the hatch. Drill four 1/16” holes at the intersections of the lines as shown. Step 12 Remove the servo hatch cover and re-drill the holes using a 5/64" drill bit. Use 2–3 drops of thin CA to harden the underlying wood. This will prevent the screws from crushing the wood when they are tightened. Secure the hatch using four #2 x 3/8" screws.

Section 6: Flap Linkages Required Parts • Wing assembly • Control horn (2) • Mounting screws (6) • Metal clevis (4) • Clevis keeper (4) • 4-40 nuts (4) • 4-40 x 1-1/2" threaded rod (2) • #2 x 3/8” screws (6) Step 3 Remove the back plate from the control horn using side cutters or a sharp hobby knife. Use a 5/64" drill bit to drill out the mounting holes in the control horn.

Section 6: Flap Linkages Step 5 Drill three 1/16" holes at the locations marked in the previous step. The holes only need to be 5/16" deep; don’t drill through the top of the flap. Step 7 Attach the control horn using three #2 x 3/8" screws. Step 8 Attach the flap control linkage to the flap control horn. Step 6 Install one of the #2 x 3/8" screws into a hole drilled, then remove it. Place 2–3 drops of thin CA into the hole to harden the wood.

Section 7: Retract Servo Installation Required Parts • 4-40 x 10-1/2" threaded rod (2) • Right and left wing panels • Retract servo with hardware (2) (JRPS703) • Easy connector (2) • Connector back plate (2) • 4-40 x 1/4" screw (2) • Metal clevis (2) • Clevis keeper (2) • 4-40 nut (2) Required Tools and Adhesives • Threadlocking compound • Drill Bit: 1/16", 7/64" • Drill • Phillips screwdriver • 3/32" hex wrench • Hobby knife • Side cutters • Felt-tipped pen Note: The retract mechanism for the P-51 comes pr

Section 7: Retract Servo Installation Step 5 Re-install the retract back into the wing. Guide the retract pushrod through the wing and into the opening for the retract servo. Secure the retract using the screws removed in Step 1. Step 6 Install the servo mounting hardware included with your retract servo, (rubber grommets and eyelets). With the servo wheel removed, install the servo as shown, with the output shaft towards the root of the wing.

Section 7: Retract Servo Installation Step 11 With the retract servo in the retracted position, push the retract linkage to manually retract the landing gear. Install a 4-40 x 1/4" screw into the easy connector and tighten it to secure the retract linkage. Photo for Step 12 Photo for Step 12 Step 12 Cycle the retract system several times to make sure there is no binding. Also check to verify the gear locks in both the extended and retracted positions.

Section 8: Main Landing Gear and Wheel Fairings Step 2 Slide the axle mount onto the landing gear strut. Apply a drop of thread locking compound onto a 6-32 set screw. Secure the axle mount using the 6-32 set screw, making sure to tighten the screw onto the flat spot on the strut. Step 3 File a flat spot onto the axle. Slide the axle into the axle mount. Apply a drop of thread locking compound onto an 8-32 set screw. Use the set screw to secure the axle.

Section 8: Main Landing Gear and Wheel Fairings Step 7 Check the fit of the wheel in the wheel well when the gear is retracted. Make any necessary adjustments so the wheel does not rub the wheel well when the gear is retracted or extended. Step 9 Draw two small marks on the landing gear door that will indicate the location of the landing gear strut. Mark the landing gear where the lower edge of the landing gear door will be positioned. Step 8 Locate the correct landing gear door tape it into position.

Section 8: Main Landing Gear and Wheel Fairings Step 11 Position the gear door mounts as follows: Position mount near the wheel so it is almost touching the wheel well. Position the mount near the retract mechanism slightly below the wheel well. Photo for Step 14 Step 15 Secure the landing gear door to the mounting brackets using four #4 x 7/16" screws. Step 12 Extend the retract. Position the landing gear door so the centerline and lower edge marks are aligned.

Section 8: Main Landing Gear and Wheel Fairings Step 17 Once the landing gear door has been adjusted, move the retracts to the extended position. Apply a few drops of thin CA to the mounts to lock in their positions on the landing gear strut. Step 18 Apply a few drops of thick CA to the screws to prevent them from loosening during flight. You may also want to trim off the excess screw for a cleaner look. Step 19 Repeat Steps 1 through 18 for the remaining retract.

Section 9: Joining the Wing Step 3 Locate the wing joiner and mark a centerline on the joiner. Step 5 With the wing panels together, check for correct dihedral. Place the wing on a large flat surface with one panel resting flat on the surface. The opposite wing tip should be 7 3/8" from the work surface. Once satisfied with the fit, separate the wing panels and remove the wing joiner. Step 4 Without using any glue, test the fit of the wing panels and wing joiner.

Section 9: Joining the Wing Step 7 Completely coat one half of the wing joiner with epoxy up to the line drawn in Step 1. Be sure to apply epoxy to the top and bottom of the joiner also. Insert the epoxy coated side of the joiner into the wing joiner cavity up to the mark on the joiner. If you have used enough epoxy, it will ooze out of the cavity as the joiner is installed. Step 8 Apply a generous amount of epoxy to the joiner cavity of the opposite wing panel.

Section 10: Mounting the Wing to the Fuselage Required Parts • Assembled wing • Fuselage • Plywood wing bolt plate (2) • 1/4-20 x 2" nylon bolts (2) Step 3 Mix 1/2 ounce of 6-minute epoxy and coat both the wing and plywood plate. Align the plate back onto the wing and clamp it in position. Remove any excess epoxy using paper towels and rubbing alcohol. Required Tools and Adhesives • 6-minute epoxy • Screwdriver (slotted) • Hobby knife • Felt-tipped pen Step 1 Locate the plywood wing bolt plate.

Section 11: Lower Air Intake Installation Required Parts • Air scoop • Plastic guide tubes (2) • Plywood tube locators (2) Step 3 Place a piece of wax paper between the fuselage and wing, then bolt the wing onto the fuselage. Required Tools and Adhesives • Medium CA • Thick CA • Razor saw • Hobby knife • Felt-tipped pen • Medium grit sandpaper Step 1 Use a felt-tipped pen to trace around the heads of the wing bolts. Step 4 Use medium grit sandpaper to lightly sand the inside edge of the air scoop.

Section 11: Lower Air Intake Installation Step 5 Position the air scoop onto the wing bolt plates. It should fit snug onto the plates. Remove the air scoop, and apply a thin bead of medium CA around the bottom edge of the air scoop. Place it back into position and allow the CA to cure before proceeding. Step 6 Remove the wing from the fuselage.Try to keep the wing bolts in the wing. Once the wing is removed, slide the plastic guide tubes through the scoop and over the heads of the wing bolts.

Section 11: Lower Air Intake Installation Step 9 Remove the excess tube using a razor saw and hobby knife. Section 12: Stabilizer Installation Required Parts • Fuselage • Stabilizer (right and left) • Stabilizer tube (short) • Stabilizer tube (long) • #2 x 3/8" screw (2) Required Tools • Drill Bit: 3/32" • Phillips screwdriver 34 • Drill Step 1 Locate both of the stabilizer tubes, short and long.

Section 12: Stabilizer Installation Step 2 Slide the tubes into the fuselage. The hole in the stabilizer faces the bottom of the plane. Step 4 Use a 3/32" drill bit to drill through the hole in the stabilizer into the stabilizer tube. Be very careful to only drill through the tube, not through the top of the stabilizer. Step 3 Slide the remaining stabilizer half onto the tubes. Step 5 Secure the tube in the one stab half using a #2 x 3/8" screw. Step 6 Repeat Steps 4 and 5 for the remaining stab half.

Section 13: Hinging the Elevators Required Parts • Stabilizer • CA hinges (6) • Elevator (right and left) Required Tools and Adhesives • T-Pins • Thin CA • Paper towels • CA remover/debonder Step 3 Slide the elevator onto the stabilizer until there is only a slight gap between the stabilizer and elevator. Remove the T-pins and snug the elevator against the stabilizer. Position the elevator so the tip aligns with the tip of the stabilizer. Step 1 Locate the hardwood control horn mount in the elevator.

Section 13: Hinging the Elevators Step 5 Turn the fuselage over, deflect the elevator in the opposite direction, and apply thin CA to the other side of the hinges as described in the previous step. Make sure the thin CA penetrates completely into both the elevator and stabilizer. Step 7 Firmly grasp the elevator and stabilizer and gently pull them apart to ensure the hinges are secure and cannot be pulled apart. Use caution when gripping them to avoid crushing the structure.

Section 14: Hinging the Rudder Required Parts • Fuselage assembly • CA hinges (3) • Rudder Required Tools and Adhesives • T-Pins • Thin CA • Paper towels • CA remover/debonder Step 2 Slide the rudder onto the fin. Align the top of the rudder with the top of the fin. Remove the T-pins and use thin CA to glue the hinges into position. Apply CA to both sides of the hinges. Note: Hinging the rudder follows the same procedure as hinging the ailerons and elevators.

Section 15: Tail Wheel Installation Required Parts • Pushrod wire (33-5/8" long) • Nylon clevis • Clevis keeper • Wheel collar (2) • M3 x 8 screw • #2 x 3/8" screw (4) • Tail wheel • Wire tail gear • Tail gear steering arm • Tail wheel Step 2 File a flat spot on the tail gear wire. Position the flat off-center slightly as shown in the photo. Required Tools and Adhesives • Pliers • 1.5mm hex wrench • Drill Bit: #20 • Drill • File • Side cutters • Threadlocking compound Step 1 Locate the tail wheel.

Section 15: Tail Wheel Installation Step 4 Slide a clevis keeper onto a nylon clevis. Thread the clevis onto the wire a minimum of 10 turns. Step 7 Position the steering arm in the center of the pre-installed tail gear mount. Make sure the set screw in the arm is facing forward. Step 5 Locate the tail gear steering arm. Use side cutters to remove the outermost hole from the arm. Step 8 Slide the tail gear wire through the mount and steering arm.

Section 15: Tail Wheel Installation Step 9 Slide a wheel collar onto the tail gear wire, then the tail wheel. Finally, slide another wheel collar on, and use an M3 x 8 screw to secure the outer collar. Use a little threadlocking compound on the screw to prevent it from vibrating loose in flight. Step 10 Secure the tail gear door cover using four #2 x 3/8" screws.

Section 16: Fuel Tank Assembly Step 2 Locate the rubber stopper. Insert the shorter metal fuel tube into one of the holes in the stopper so that an equal amount of tube extends from each side of the stopper. This tube will be the fuel tank pickup that provides fuel to the engine. Step 3 Slide the smaller cap over the tube on the smaller end of the rubber stopper. This end will be inserted into the fuel tank. The larger cap is placed on the side of the rubber stopper that makes the cap.

Section 16: Fuel Tank Assembly Step 7 Carefully insert the stopper assembly into the fuel tank. Note the position of the vent tube; it must be up at the top portion of the fuel tank to function properly. Also, it may be necessary to shorten the length of the fuel pickup tubing to make sure the clunk does not rub against the back of the fuel tank. You should be able to turn the tank to any attitude and the clunk will fall to the lowest point. (All directions except for having the stopper facing down.

Section 17A: Engine Installation (Saito 180GK) Required Parts • Fuselage • Engine mount (2) • #8 washers (8) • Engine • 8-32 x 1 1/4" screws (8) Step 1 Locate the engine mount and the associated hardware. • 8-32 nylon lock nuts (4) • Plywood engine mount spacers (2) Required Tools and Adhesives • Phillips screwdriver • Measuring device • Adjustable wrench • 11/32" socket wrench Note: There are two engine installations in this instruction manual (Section 17A and Section 17B).

Section 17A: Engine Installation (Saito 180GK) Step 3 Prepare the engine mount for installation by sliding four 8-32 bolts and washers through the engine mount. Position the plywood engine mount spacers onto the bolts as shown. Step 4 Install the engine mount. Step 5 Install the spinner back plate and propeller. Position the engine so there is between 1/16" and 1/8" gap between the back plate and fuselage. Step 6 Remove the spinner back plate and tighten the screws holding the engine to the mount.

Section 17B: Engine Installation (Saito 200 TI) Required Parts • Fuselage • #8 washers (4) • Felt-tipped pen • Engine • 8-32 x 1-1/4" screws (4) • Associated engine mount Required Tools and Adhesives • Phillips screwdriver • Drill • Adjustable wrench • Socket Wrench: 11/32" • Drill Bit: 1/4" • Measuring device Step 2 If you must remove the blind nuts, thread an 8-32 bolt partially into the nut. Lightly tap the bolt to pop the blind nut away from the firewall.

Section 17B: Engine Installation (Saito 200 TI) Important: The stock engine mount is offset 1/4" towards the top of the fuselage. Measure 1/4" towards the bottom of the fuse and make two marks for the horizontal centerline. Step 6 Transfer the measurements made in the last step to the firewall. Remember to divide by two and measure from the centerline. Step 4 Connect the marks drawn in the previous step. Your new engine mount will centered here the two lines cross.

Section 17B: Engine Installation (Saito 200 TI) Step 7 Drill the locations for the new bolts using a 1/4" drill bit. Step 9 Install any accessories that may be required for your particular engine. In the case of the Saito 200TI, a needed valve must be attached to the mount. Make any necessary adjustments to the fuselage to provide clearance if required. Step 8 Install your particular motor mount using four 8-32 bolts, four washers and the blind nuts removed in Step 2.

Section 18: Throttle Pushrod and Fuel Tank Required Parts • Fuel tank assembly • Foam: 1/4", 1/2" • Throttle pushrod tube (15") • Throttle pushrod (17 1/4") • Fuel tubing (red and green) Step 2 Test fit the throttle pushrod tube through the firewalland into the fuselage. Once satisfied with the fit, mix1/4 ounce of 6-minute epoxy and glue the pushrodinto the firewall. Allow the epoxy to fully cure before continuing.

Section 18: Throttle Pushrod and Fuel Tank Step 4 Install the throttle pushrod into the tube and connect it to the throttle arm. You may need to remove the throttle control arm of the carburetor to connect the Z-bend to the throttle arm. Step 6 Connect the two pieces of fuel tubing to the fuel tanks pickup and vent tubes. Install the fuel tank into the fuselage from the radio compartment. The stopper and fuel tubes will pass through the round hole in the firewall.

Section 19: Radio Installation Required Parts • Fuselage assembly • Receiver • Switch harness • Foam • Receiver battery • Servos (4) (not included) Required Tools and Adhesives • Drill Bit: 1/16" • Drill • Thin CA • Hobby knife Step 1 Install the recommended servo hardware (grommets and eyelets) supplied with your radio system onto four servos (elevator (2), rudder and throttle). Temporarily install the four servos into the openings and mark the location of the servo mounting screws.

Section 19: Radio Installation Step 5 Connect any necessary extensions and Y-harnesses necessary to connect up the retract, aileron and flap servos. Connect the elevator, rudder and throttle servo leads to the receiver. Step 6 Wrap the receiver in protective foam to prevent damage that may be cause by engine vibration. 52 Step 7 Wrap the receiver battery in protective foam as you did the receiver. Temporarily mount the receiver and battery into the fuselage.

Section 20: Rudder and Elevator Linkages Required Parts • Fuselage assembly • Pushrod wires (3) • Nylon clevis (3) • Clevis keeper (3) • Nylon wire keepers (4) • Control horns (3) • #2 nuts (6) • #2 x 3/8" screw (6) • #2 x 1 5/8" threaded rods (3) Step 2 Slide a clevis keeper onto a nylon clevis. Thread the clevis onto the wire a minimum of 10 turns. Repeat this step for both elevators’ linkages and the rudder linkage.

Section 20: Rudder and Elevator Linkages Step 4 Attach the clevis to the control horn. Position the control horn on the elevator so the control rod is straight, and the holes in the control horn aligns with the hinge line of the elevator. Mark the position for the mounting holes using a felt-tipped pen. Step 6 Install one of the #2 x 3/8" screws in a hole drilled, then remove it. Place 2-3 drops of thin CA into the hole to harden the wood.

Section 20: Rudder and Elevator Linkages Step 11 Slide the wire through the outer hole in the elevator servo arm. Secure the wire using a nylon wire keeper. Photo for Step 8 Step 9 Bend the wire 90 degrees at the mark made in the previous step Step 12 Repeat Steps 3 through 11 for the remaining elevator half. Step 13 Center the rudder servo electronically using the radio system. Install a servo arm onto the rudder servo. Physically place the tail wheel in neutral.

Section 20: Rudder and Elevator Linkages Step 17 Remove the back plate from the last control horn using side cutters or a sharp hobby knife. Photo for Step 20 Step 18 Attach the clevis to the control horn. Position the control horn on the rudder so the control rod is straight, and the front edge of the control horn aligns with the front edge of the bevel on the rudder. Mark the position for the mounting holes using a felt-tipped pen.

Section 21: Throttle Linkage Installation Required Parts • Easy connector • Connector back plate • M3 x 8 screw Required Tools and Adhesives • Phillips screwdriver • Pliers • Drill Bit: 3/32" • Drill Step 1 Use a 3/32" drill bit to drill out the holes in a servo arm. Attach an easy connector to the arm using a connector back plate. Step 3 Move the throttle stick and trim to low. Check to make sure the carburetor will move to the low position when operating the servo.

Section 22: Attaching the Cowl Required Parts • Fuselage assembly • Mounting screws (6) • Cowl Required Tools and Adhesives • Felt-tipped pen • Hobby knife • Moto-tool w/cut-off wheel and sanding drum Step 1 Mount the cowl using the #2 screws provided. Make the appropriate cutouts in the cowl for the muffler exhaust and engine cooling. Note: If you are using the Saito 200TI, it will be required to install a baffle inside the cowl to direct air over the rear cylinder. Make the baffle from 1/16" balsa.

Section 23: Cockpit Details Step 2 Cut out the instrument panel decal and apply. Step 3 Glue the cockpit details to the fuselage using Shoe Goo or similar type adhesive, using the pictures on thebox as a guide. Use tape to hold the parts until the adhesive cures. Step 4 Glue the clear gun site into position using 6-minute epoxy. Step 5 Glue the exhaust into position using Shoe Goo. Step 6 Glue the guns into position using Shoe Goo.

Section 24: Attaching the Canopy Required Parts • Fuselage assembly • Canopy Required Tools and Adhesives • Canopy scissors • Canopy glue (RC560) Step 1 Glue the canopy to the fuselage using RC560 canopy glue. Tape the canopy in place with masking tape and allow the glue to cure overnight.

Control Throws and Center of Gravity Recommended CG Location An important part of preparing the aircraft for flight is properly balancing the model. This is especially important when various engines are mounted. Caution: Do not inadvertently skip this step! The recommended Center of Gravity (C.G.) location for the P-51 1.50 is 6 3/8" behind the leading edge of the wing measured at the fuselage sides.

2003 Official AMA National Model Aircraft Safety Code Effective January 1, 2003 Model Flying MUST be in accordance with this Code in order for AMA Liability Protection to apply. GENERAL 1) I will not fly my model aircraft in sanctioned events, air shows or model flying demonstrations until it has been proven to be airworthy by having been previously, successfully flight tested. 2) I will not fly my model higher than approximately 400 feet within 3 miles of an airport without notifying the airport operator.

2003 Official AMA National Model Aircraft Safety Code Continued 4) I will operate my model using only radio control frequencies currently allowed by the Federal Communications Commission. (Only properly licensed Amateurs are authorized to operate equipment on Amateur Band frequencies.) 5) Flying sites separated by three miles or more are considered safe from site-to site interference, even when both sites use the same frequencies.

® TM WE GET PEOPLE FLYING # 5768 © 2003, Horizon Hobby, Inc. 4105 Fieldstone Road Champaign, Illinois 61822 (217) 355-9511 www.horizonhobby.