Specifications

Table Of Contents

- Table of Contents

- Contents of Kit

- Additional Required Equipment

- Additional Required Tools and Adhesives

- Other Items Needed (not included in the kit)

- Warning

- Before Starting Assembly

- Using the Manual

- Warranty Information

- Section 1: Hinging the Ailerons

- Section 2: Aileron Servo Installation

- Section 3: Aileron Linkages

- Section 4: Hinging the Flaps

- Section 5: Flap Servo Installation

- Section 6: Flap Linkages

- Section 7: Retract Servo Installation

- Section 8: Main Landing Gear and Wheel Doors

- Section 9: Joining the Wing

- Section 10: Mounting the Wing to the Fuselage

- Section 11: Lower Air Intake Installation

- Section 12: Stabilizer Installation

- Section 13: Hinging the Elevators

- Section 14: Hinging the Rudder

- Section 15: Tail Wheel Installation

- Section 16: Fuel Tank Assembly

- Section 17A: Engine Installation

- Section 17B: Engine Installation

- Section 18: Throttle Pushrod and Fuel Tank

- Section 19: Radio Installation

- Section 20: Rudder and Elevator Linkages

- Section 21: Throttle Linkage Installation

- Section 22: Attaching the Cowl

- Section 23: Cockpit Details

- Section 24: Attaching the Canopy

- Section 25: Applying the Decals

- Control Throws and Center of Gravity

- Preflight at the Field

- Adjusting the Engine

- 2003 Official AMA National Model Aircraft Safety Code

Section 8: Main Landing Gear and Wheel Fairings

25

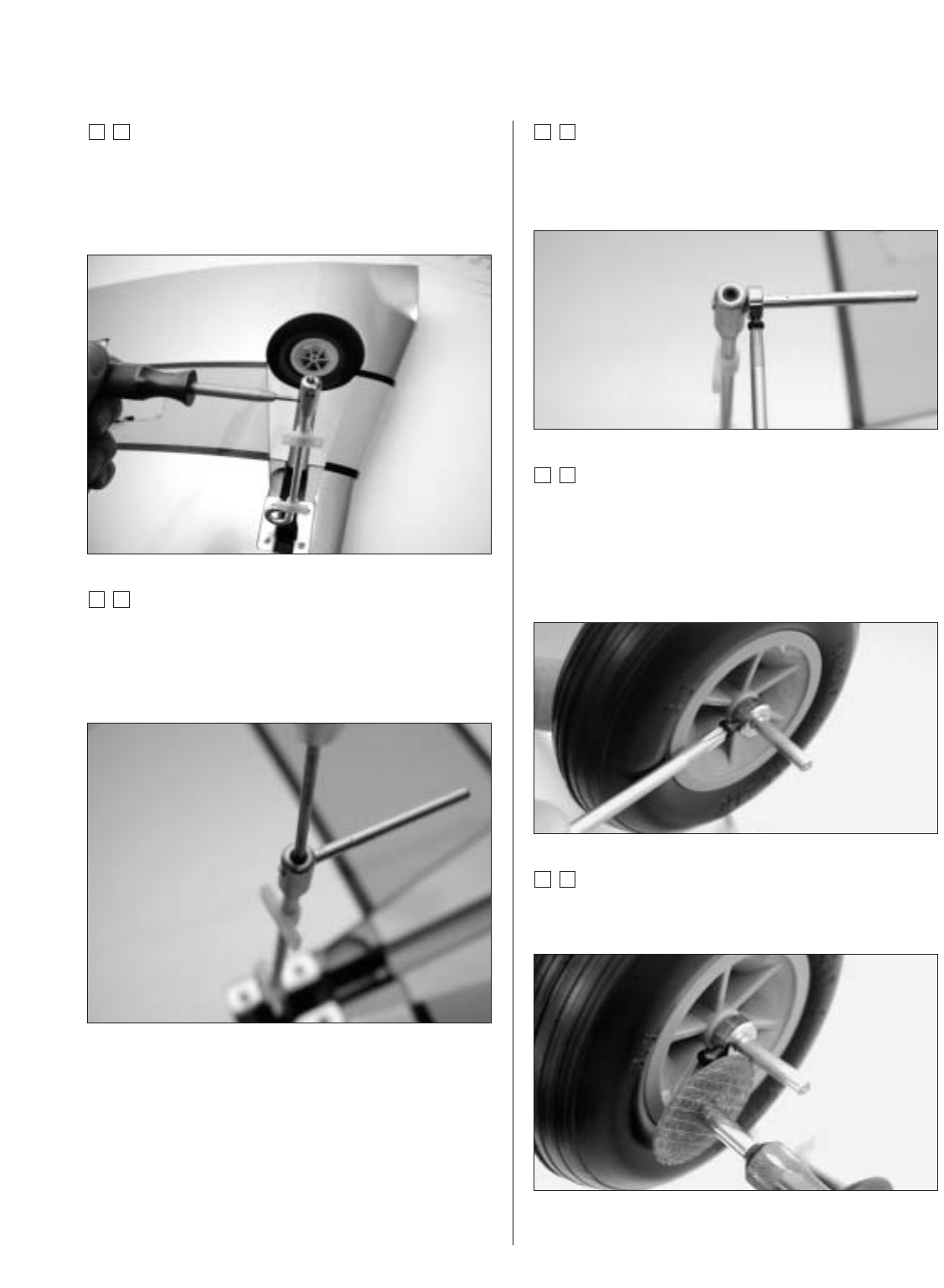

Step 2

Slide the axle mount onto the landing gear strut. Apply a

drop of thread locking compound onto a 6-32 set screw.

Secure the axle mount using the 6-32 set screw, making

sure to tighten the screw onto the flat spot on the strut.

Step 3

File a flat spot onto the axle. Slide the axle into the axle

mount. Apply a drop of thread locking compound onto an

8-32 set screw. Use the set screw to secure the axle.

Make sure to tighten the set screw onto the flat spot.

Step 4

Slide a wheel collar onto the axle. Position the wheel

collar against the axle mount, and then secure its location

using an M3 x 8 screw.

Step 5

Slide the wheel onto the axle. Make sure the wheel can

rotate freely on the axle. Slide another wheel collar onto

the axle and use an M3 x 8 screw to finish up the step.

Remember to file a flat spot on the axle, as well as use

threadlocking compound.

Step 6

Remove the excess axle beyond the wheel collar using

a Moto-tool w/cut-off wheel