Specification Sheet

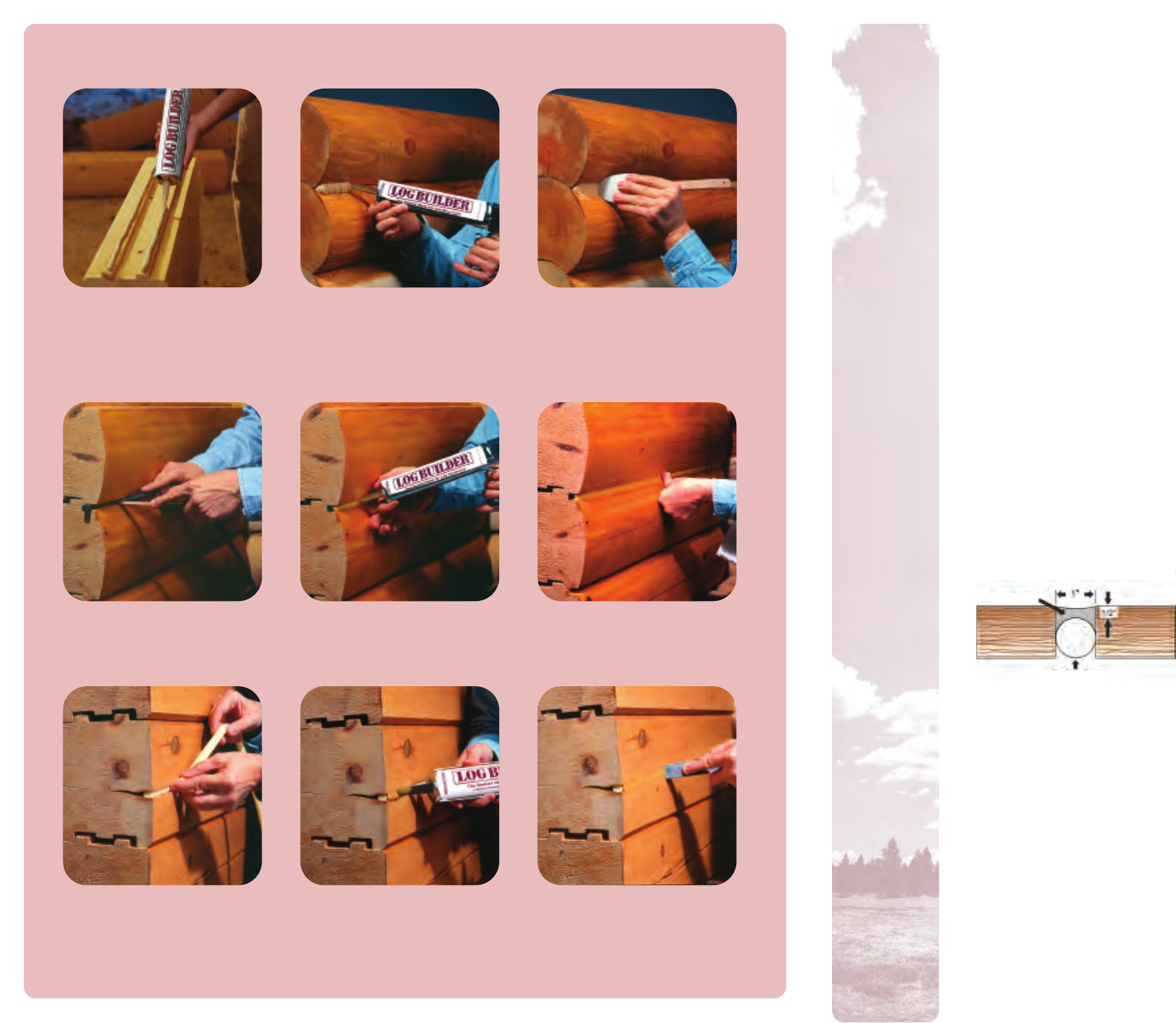

1 – Gun Log Builder into

clean, stained joints.

2 – Tool to ensure a tight seal to the

top and bottom of the caulk line

leaving at least 1/4” depth of

caulk in the center of the joint.*

Apply bead(s) according to the log home

manufacturer’s instructions. Stack the

next log and repeat. Don’t allow

caulk to skin over prior to stacking.

Stacking Application

2 – Gun Log Builder over

the backer rod.

3 – Tool to ensure a tight seal to the

top and bottom of the caulk line.

1 – Install backer rod into the caulk

well of clean, stained logs.

Milled Tongue & Groove Logs with a Caulk Well

Swedish Cope Logs

up moisture), will undergo moderate levels of stress

on sealants applied to them. An occasional log will

randomly and unpredictably twist, shrink or warp in

response to these moisture changes, moving more

than any sealant can possibly handle.

When this extreme movement occurs, it will cause

the sealant to fail either cohesively or adhesively. If

the failure is cohesive (sealant splits apart),

then the repair is performed by simply cleaning the

surfaces of the failed sealant and reapplying more.

If the failure is adhesive (sealant pulls cleanly away

from the substrate), then the sealant usually needs to

be removed and completely redone.

Warranty

Sashco Sealants warrants that Log Builder will

stretch up to 100% of original joint size (± 50%) and

will not pull away or center tear when applied in

accordance to the Log Builder Data Tec (LBR-002).

If you are dissatisfied at any time with Log Builder’s

performance in these areas, return proof of purchase

to Sashco. Limited to product replacement only.

Sashco warrants this product will substantially

meet published specifications on the date of sale. If it

fails to do so, return unused portion with original

sales receipt for replacement or refund, at Sashco’s

sole option. These are purchaser’s sole and exclusive

remedies for any breach of warranty. Purchaser

must determine suitability of product for purchaser’s

specific needs and assumes all risk associated

with its use.

Except as stated above there are no warranties for

this product. The foregoing express warranty is in

lieu of all other

warranties, express or implied,

including without limitation implied warranties of

merchantability or fitness for a particular pur-

pose, which warranties are specifically excluded

and disclaimed. This Limited Warranty gives you

specific legal rights. Y

ou may have other rights which

vary from state to state. Some states do not allow

exclusion of implied warranties in consumer or other

sales, limitations on the duration of implied war-

ranties, or exclusion or limitation of incidental or

consequential damages. Thus, the limitations or

exclusions contained above may not apply to you

depending upon your specific circumstances.

First Aid

EYES: Immediately flush with large quantities

of water for at least 15 minutes. If irritation

persists, see a medical doctor.

SKIN: Wash with soap and water and rinse

thoroughly

. Wash contaminated clothing before use.

INHALATION: Remove to fresh air.

INGESTION: If large quantities are

swallowed, DO NOT INDUCE VOMITING -

seek medical help.

2 3

2 – Gun Log Builder over

the backer rod.

3 – Tool Log Builder.1 – Install backer rod into a clean, stained

check to the appropriate depth. (See

Fundamental Application Guidelines.)

Checks

* NOTE: Use a bond breaker (i.e., backer rod) when significant log movement could occur. When movement is known to be minimal (as with many older homes)

using backer rod is still best, but usually less critical.

Methods of Application

When using 5-gallon pails, Sashco’s patented Snorkler

®

pumping system, grout bags, or bulk loading guns may

be used. Use a caulking gun when using either the 29

oz. or 10.5 oz. cartridges of Log Builder. When using

a cartridge, cut the spout at a 45˚ angle to desired

bead size. Log Builder requires no heating prior to

application but will dispense easier when kept

warm before use.

Tooling

Log Builder should be tooled directly after applica-

tion to ensure good adhesion and a smooth looking

bead. Log Builder may be tooled with ordinary

masonry-type tooling blades, a wetted finger, or a

damp polyethylene foam brush. Work the material

smooth, tooling Log Builder tightly to the surfaces,

keeping a rag handy for clean up.

Checks and Cracks

Logs tend to take on water from rain and snow

through cracks and checks; therefore, it is important to

pay close attention to these openings and prep and seal

them properly. Note: Most small checks should not be

caulked. Only the larger ones (1/4” or larger) should

be sealed with backer rod and caulk.

Joint Design

Joint width should be a minimum of 1/4”, but no

larger than 2”, and 4 times the anticipated joint move-

ment. For example, if you anticipate log movement

of 1/8”, bead

width should

be about 1/2”.

For joints 1”

or more, the

depth should

be 3/8” to

1/2”. The

depth of joints less than 1” wide should be half the

width but no less than 1/4”. (Joint depth, overall,

should be between 1/4” and 1/2”.)

Clean-up & Disposal

Clean excess product off surfaces (before it cures)

with a putty knife and/or a damp rag. Dispose of Log

Builder in accordance with local regulations. Do not

dispose of in drinking water supplies. Water may be

used for cleaning hands, surfaces and equipment.

Solvents are not required for clean-up.

Logs Move!

Occasionally, a small number of logs on any home

may undergo extreme movement. This movement is a

natural part of the logs moisture content adjusting to

their new settings. Most logs, as they dry (or go

through the repeated process of taking on and giving

Conceal

Backer Rod

Proper Joint Design: Depth = 1/2 width