MDT5N25 & MDT5N40 Ice Maker-Dispenser Service Manual

Table Of Contents

- Table of Contents

- FOR THE INSTALLER: Specifications Page 2

- FOR THE INSTALLER: Environmental Limitations Page 3

- FOR THE INSTALLER Page 4

- FOR THE INSTALLER: Wall Mount Kit Page 5

- FOR THE PLUMBER Page 6

- FOR THE ELECTRICIAN Page 7

- FOR THE INSTALLER: Final Check List Page 8

- INITIAL START UP Page 9

- COMPONENT DESCRIPTION Page 10

- COMPONENT DESCRIPTION Page 11

- COMPONENT DESCRIPTION: Control Box Page 12

- ELECTRICAL SEQUENCE Page 13

- OPERATION: Water Page 14

- OPERATION: Refrigeration Page 15

- OPERATION: Ice Vending Page 16

- DISPENSE AREA SANITATION Page 17

- CLEANING and SANITIZING Page 18

- MAINTENANCE AND CLEANING Page 19

- SERVICE DIAGNOSIS Page 21

- SERVICE DIAGNOSIS: Circuit Board Page 23

- REMOVAL AND REPLACEMENT Page 24

- REMOVAL AND REPLACEMENT: Bearing And Breaker Page 25

- REMOVAL AND REPLACEMENT: Water Seal Page 27

- TO REMOVE AND REPAIR THE GEARMOTOR ASSEMBLY Page 29

- REFRIGERATION SERVICE: R-404A (HP62) Page 30

- REFRIGERATION SERVICE Page 31

- CIRCUIT BOARD SERVICE Page 32

- LIQUID CHARGING Page 32

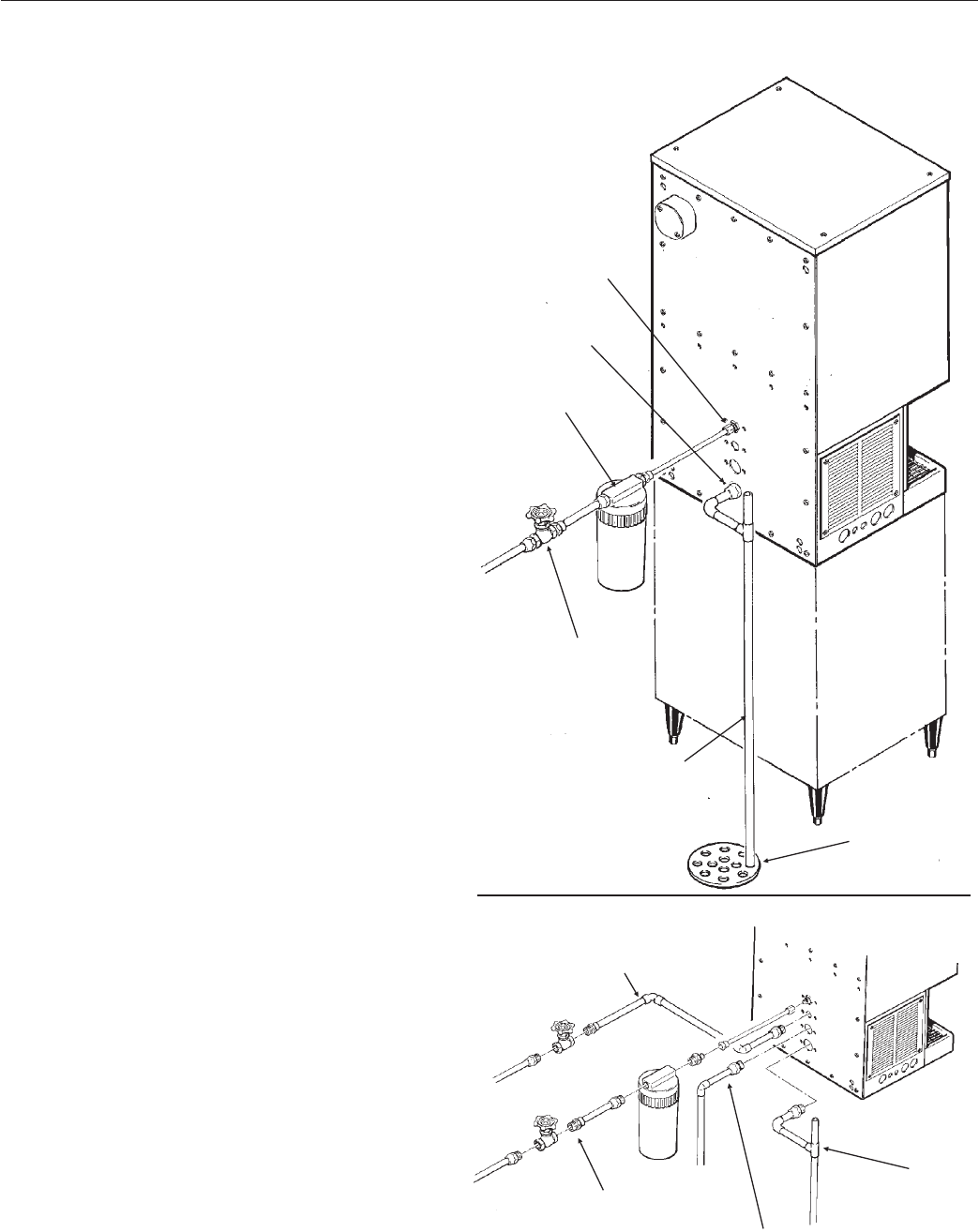

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

Water Inlet

Air Cooled Models: The recommended water

supply is clean, cold water. Use 3/8" O.D. copper

tubing, connect to the 3/8" male flare at the back of

the cabinet. Install a hand valve near the machine

to control the water supply.

Water Treatment: In most areas, a water filter of

some type will be useful. In areas where the water

is highly concentrated with minerals the water

should be tested by a water treatment specialist,

and the recommendations of the specialist

regarding filtration and/or treatment should be

followed.

Water Cooled Models: A separate 3/8" O.D.

copper line is recommended, with a separate hand

valve to control it. It is connected to a 3/8" FPT

condenser inlet at the back of the cabinet. The

water pressure to all lines must always be above

20 psig, and below 80 psig.

Drains

Air Cooled Models: There is one 3/4" FPT drain

at the back of the cabinet, the drain line is of the

gravity type, and 1/4 inch per foot fall is an

acceptable pitch for the drain tubing. There should

be a vent at the highest point of the drain line, and

the ideal drain receptacle would be a trapped and

vented floor drain. Use only 3/4" rigid tubing.

Water Cooled Models: In addition to the above

mentioned drain, a separate condenser drain must

be installed. Connect it to the 1/2" condenser drain

connection at the back of the cabinet.

MDT5N25 & MDT5N40

May 2001

Page 6

WATER INLET

CABINET

DRAIN

OPTIONAL

WATER

FILTER

WATER INLET

SHUT OFF

VALVE

VENTED

DRAIN TUBE

FLOOR DRAIN

WATER COOLED DETAIL

Condenser

WATER INLET

POTABLE

WATER INLET

Condenser

DRAIN

CABINET

DRAIN