MDT5N25 & MDT5N40 Ice Maker-Dispenser Service Manual

Table Of Contents

- Table of Contents

- FOR THE INSTALLER: Specifications Page 2

- FOR THE INSTALLER: Environmental Limitations Page 3

- FOR THE INSTALLER Page 4

- FOR THE INSTALLER: Wall Mount Kit Page 5

- FOR THE PLUMBER Page 6

- FOR THE ELECTRICIAN Page 7

- FOR THE INSTALLER: Final Check List Page 8

- INITIAL START UP Page 9

- COMPONENT DESCRIPTION Page 10

- COMPONENT DESCRIPTION Page 11

- COMPONENT DESCRIPTION: Control Box Page 12

- ELECTRICAL SEQUENCE Page 13

- OPERATION: Water Page 14

- OPERATION: Refrigeration Page 15

- OPERATION: Ice Vending Page 16

- DISPENSE AREA SANITATION Page 17

- CLEANING and SANITIZING Page 18

- MAINTENANCE AND CLEANING Page 19

- SERVICE DIAGNOSIS Page 21

- SERVICE DIAGNOSIS: Circuit Board Page 23

- REMOVAL AND REPLACEMENT Page 24

- REMOVAL AND REPLACEMENT: Bearing And Breaker Page 25

- REMOVAL AND REPLACEMENT: Water Seal Page 27

- TO REMOVE AND REPAIR THE GEARMOTOR ASSEMBLY Page 29

- REFRIGERATION SERVICE: R-404A (HP62) Page 30

- REFRIGERATION SERVICE Page 31

- CIRCUIT BOARD SERVICE Page 32

- LIQUID CHARGING Page 32

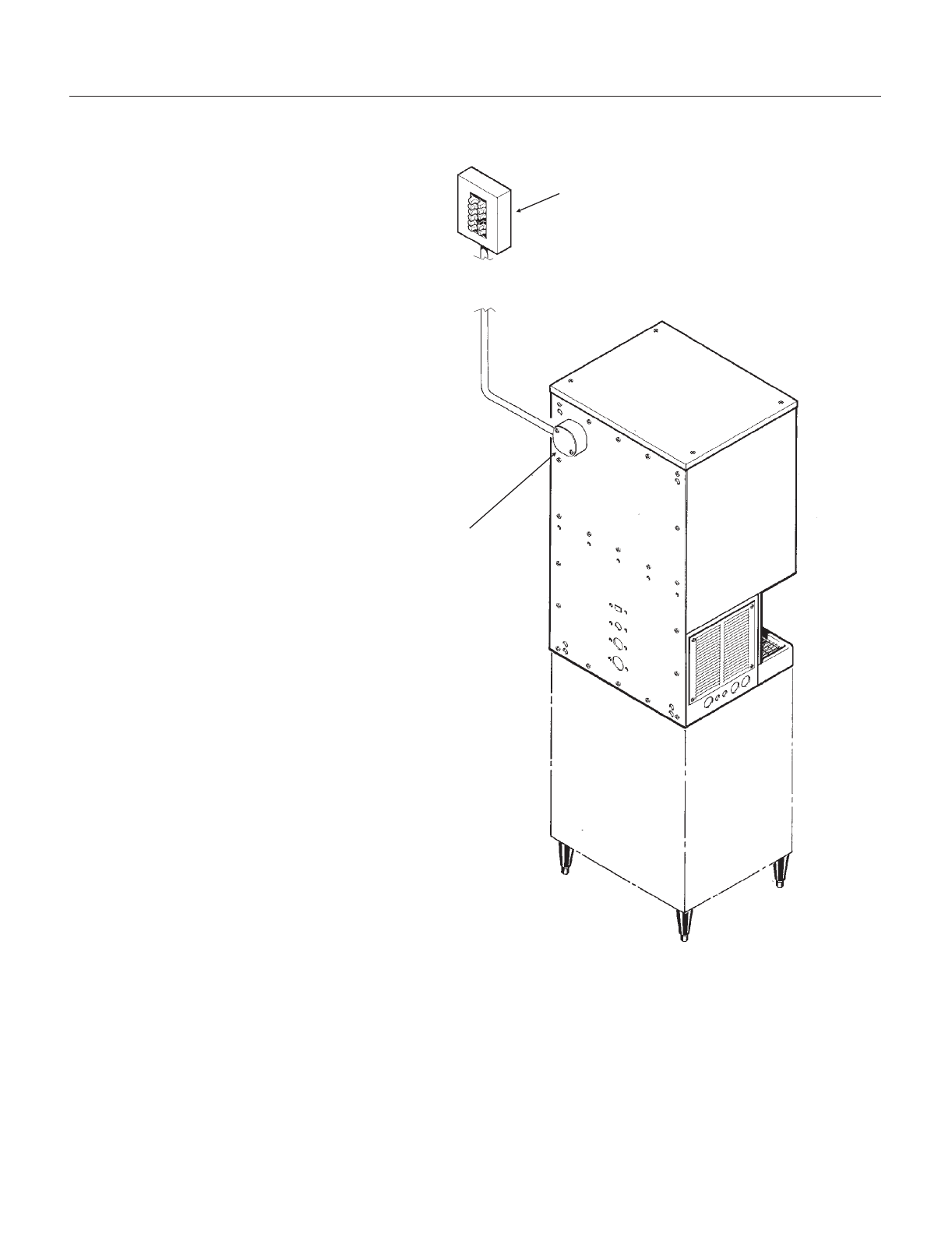

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

The electrical power to the unit is

supplied through the junction box at the

rear of the machine.

Check the nameplate (located on the

back panel) for the voltage

requirements, and for the minimum

circuit ampacity. The machine requires

a solid chassis to earth ground wire.

The ice maker should be connected to

its own electrical circuit so it would be

individually fused. Voltage variation

must remain within design limitations,

even under starting conditions.

All external wiring must conform to

national, state, and local electrical

codes. The use of a licensed

electrician is required to perform the

electrical installation.

MDT5N25 & MDT5N40

July 2003

Page 7

JUNCTION

BOX

INDIVIDUAL CIRCUIT

FOR ICE DISPENSER