User`s manual

Table Of Contents

- Safety Precautions

- Table of contents

- Chapter 1: Outline

- 1-1 Features

- 1-2 Controller

- 1-3 Measurement program

- [1] Positional deviation measurement

- [2] Degree of match inspection

- [3] Lead inspection

- [4] BGA/CSP inspection (IV-S32M/S33M)

- [5] Area measurement by binary conversion

- [6] Object counting by binary conversion

- [7] Object identification by binary conversion

- [8] Point measurements

- [9] Distance and angle measurement

- [10] Multiple position measurement (IV-S33M)

- [11] Multiple degree of match inspection (IV-S33M)

- Chapter 2 : Precautions for Use

- Chapter 3 : System Configuration

- Chapter 4 : Part Names and Functions

- Chapter 5 : Connection and Installation Methods

- Chapter 6 : Setting and Operating Outlines

- Chapter 7 : Simplified Menu Operation

- 7-1 Operation screen

- 7-2 Image display

- 7-3 Setting functions that are different with each controller

- 7-4 Setting procedures

- 7-5 Setting the operation conditions

- 7-6 Setting object types

- 7-7 Setting the shutter speed

- 7-8 Setting the positioning conditions

- 7-9 Setting the existence inspection conditions

- 7-10 Measurement triggering

- 7-11 Saving data

- 7-12 Specify the system conditions

- Chapter 8 : Specifications

- Chapter 9 : Operation Examples

- Glossary

- Appendix

- Alphabetical Index

1-9

Outline

1

Workpiece

- Inspection procedure

Pur-

pose

Exam-

ple

Appli-

cation

Detect the existence/absence and size of a workpiece when “the workpiece is one point”

or “measurement position is fixed."

- Convert the specified pixel area to binary values and measure the size of the white

area.

Check for the existence of bearings inserted by a bearing insert machine, prevent con-

tamination of different parts in automobile production lines, determine the type of water-

proof caps, check for the existence/absence of bottle labels, inspect the cuircuit traces on

PWBs, check for the presence of grease, check for existence of frozen foods.

Capture image

[Measured result]

- Workpiece area

Convert to binary values Measure (area)

[5] Area measurement by binary conversion

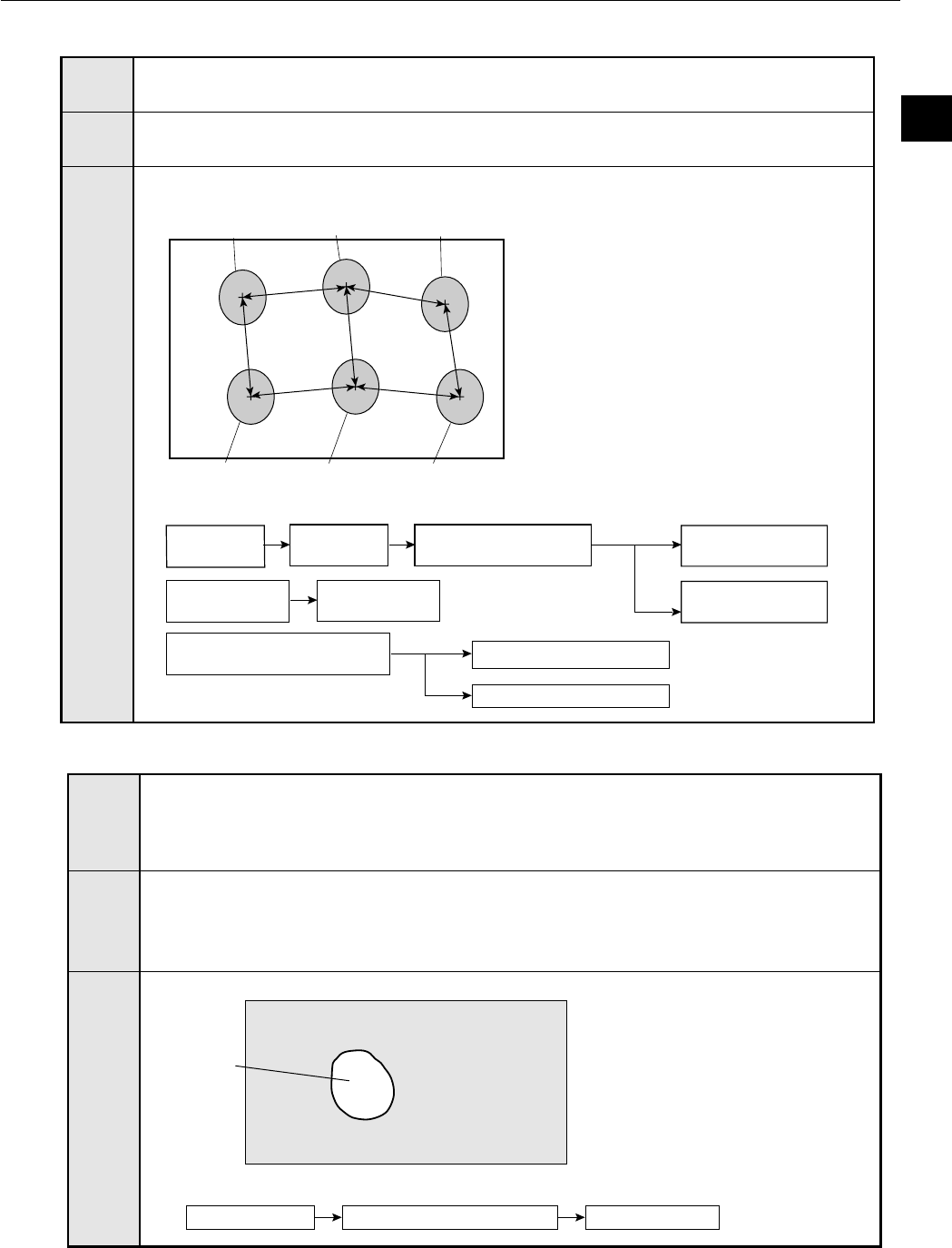

[4] BGA/CSP inspection (IV-S32M/S33M)

- Inspection procedure

[Measurement of 6 balls]

Image

capture

Binary

conversion

Measure centers

of gravity

Fillet diameters

Object identification

(numbering)

Inspecting BGA/CSP solder balls.

Area of each

object

Ball size

Distance between centers

of gravity for pairs of balls

Distance between balls

Number of balls

Object 0 Object 1 Object 2

Object 3 Object 4 Object 5

[Measured results]

- Number of objects: K

- Area of each object: R0 to R127

- Distance between centers of gravity:

(DX0, DY0) to (DX127, DY127)

- Fillet diameters: FX, FY

Measure the center of gravity, area of each object, number of objects, and fillet diameter

using the object identification function after binary conversion.

Pur-

pose

Exam-

ple

Appli-

cation