Instruction manual

MS 201 T

English

15

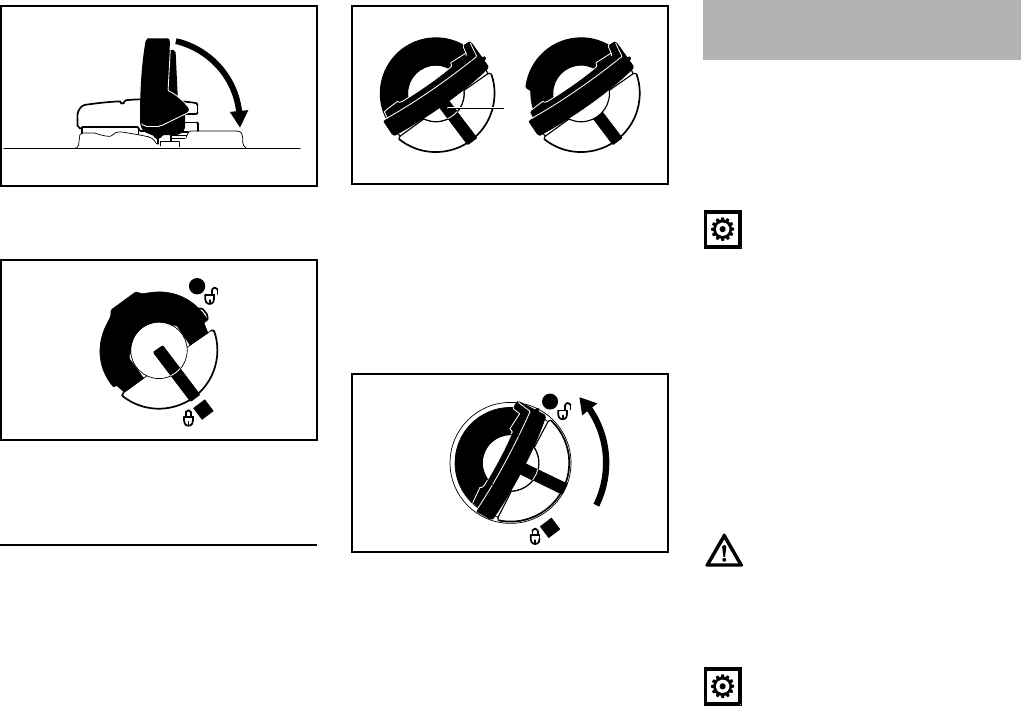

N Fold the grip down so that it is flush

with the top of the cap.

Tank cap is locked.

If the tank cap cannot be locked in the

fuel tank opening

Bottom of cap is twisted in relation to

top.

N Remove the cap from the fuel tank

and check it from above.

N Place the cap on the opening and

rotate it counterclockwise until it

engages the filler neck.

N Continue rotating the cap

counterclockwise (about a quarter

turn) – this causes the bottom of the

cap to be turned to the correct

position.

N Turn the cap clockwise and lock it in

position – see section on "Closing".

For automatic and reliable lubrication of

the chain and guide bar – use only an

environmentally compatible quality

chain and bar lubricant. Rapidly

biodegradable STIHL Bioplus is

recommended.

Biological chain oil must be resistant to

aging (e.g. STIHL Bioplus) since it will

otherwise quickly turn to resin. This

results in hard deposits that are difficult

to remove, especially in the area of the

chain drive and chain. It may even cause

the oil pump to seize.

The service life of the chain and guide

bar depends on the quality of the

lubricant. It is therefore essential to use

only a specially formulated chain

lubricant.

Do not use waste oil. Renewed contact

with waste oil can cause skin cancer.

Moreover, waste oil is environmentally

harmful.

Waste oil does not have the necessary

lubricating properties and is unsuitable

for chain lubrication.

001BA235 KN

001BA241 KN

Left: Bottom of cap is twisted –

inner mark (1) in line with

outer mark.

Right: Bottom of cap in correct posi-

tion – inner mark is under the

grip. It is not in line with the

outer mark.

1

001BA238 KN

001BA239 KN

Chain Lubricant