Installation Guide

Trademarks The trademarks USG, SHEETROCK,

the USG logo, the design elements and colors, and

related marks are trademarks of USG Corporation

or its aliates. Notice We shall not be liable for

incidental and consequential damages, directly

or indirectly sustained, nor for any loss

cause by application of these goods

not in accordance with current printed

instructions or for other than the

intended use. Our liability is expressly

limited to replacement of defective

goods. Any claim shall be deemed

waived unless made in writing to us

within thirty (30) days from date it

was or reasonably should have been

discovered. Safety First! Follow good safety and

industrial hygiene practices during handling and

installation of all products and systems. Take

necessary precautions and wear the appropriate

personal protective equipment as needed.

Read material safety data sheets and related

literature on products before specification and/

or installation.

Manufactured by

United States Gypsum Company

550 West Adams Street, Chicago, IL 60661

Product Information See usg.com for the most

up-to-date product information.

800-USG-4YOU (874-4968) / usg.com

R24/8-15 © 2015 USG Corporation and/or its

aliates. All rights reserved. Printed in U.S.A.

Tools and Materials

– Drop cloths

– Drywall finishing knives

– Drywall hammer

– Drywall nails or screws

– Dust mask

– Marking pencil

– Metal tape measure

– Portable work light and

extension cord

– Safety goggles

– Step ladder

– 4 ft. T-square

– Utility (keyhole) saw

– Utility knife & extra blades

Optional

– Panel adhesive and

caulk gun

– Panel lifter

– Screwgun

Installation Guide

USG Sheetrock® Brand gypsum panels (drywall) are specially formulated to ensure

easy scoring, clean snapping and enhanced strength from core to face.

Planning the Job

Measure walls and ceilings to determine the square

footage of each area being covered. Divide the

calculated area by the square footage of the panels

to be used (4 ft. x 8 ft. = 32 sq. ft., 4 ft. x 10 ft. = 40

sq. ft., 4 ft. x 12 ft. = 48 sq. ft.) to determine the

number of panels needed.

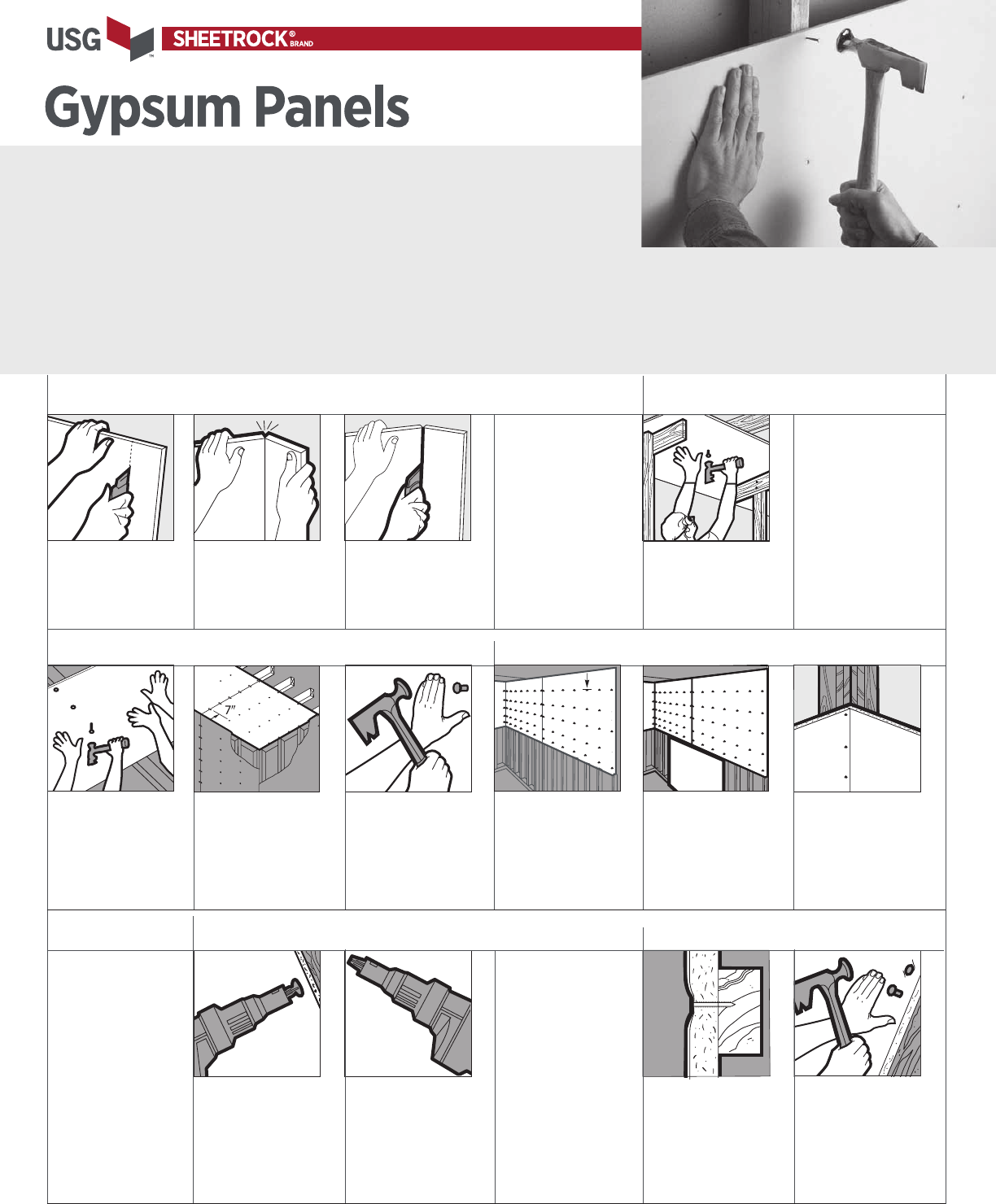

How to Cut Panels Score and Snap How to Install Panels Ceilings First...

Measure and mark panel

cuts with a T-square, then

use a utility knife to score

through paper face and

lightly into the core.

Grasp board on both sides

of the cut and snap away

from you.

Cut back paper to separate.

Sand or rasp to smooth cut

edge. Keep edge as square

as possible.

Note: Carefully measure

and draw openings for

electrical boxes and other

cutouts to ensure proper

positioning. Use utility saw

for best results.

T-braces — 1x4s nailed to

2x4 uprights that are

1/2 in. longer than floor-

to-ceiling height — ease

installation.

Optional: Rent a panel lifter.

If not using T-braces or a

panel lifter, two or more

people are needed to hold

each panel in place for

proper attachment.

Apply ceiling panels first,

starting at one corner.

Ensure that first sheet

is square on joists. Firm

contact with joists is

essential for good ceiling

attachment.

Hold panel tight against

framing and fasten to studs,

fastening center of panel

first and work toward edges.

Fasteners along panel edges

should be at least 3/8 in. in

from board edge.

Apply panels horizontally

to wall studs. Starting at

one corner, install top row

first. Position tight against

ceiling panels and apply

first nails 8 in. from the top

of the wall.

Stagger lower panels so the

vertical joints will be oset.

For inside corners, fit first

panel into corner, butt

second panel against first

and fasten the end of the

second panel to stud.

Space 1-1/4 in. drywall

screws 12 in. apart on

ceilings, 16 in. apart on

walls. For 1/2 in. - and

5/8 in. -thick panels, use

1-1/4 in. Type W bugle

head screws.

Use a screwgun or drill with

a screw depth control bit.

Sink screws just below the

panel surface, leaving the

paper intact. Ensure that

fasteners are properly sunk

by drawing a knife across

the surface.

Optional: Adhesive

attachment. Before

installing panels, apply

adhesive to clean, oil-free

framing, per instructions on

adhesive cartridge. Nails

or screws are still required

when adhesive is used.

Space nails 7 in. apart on

ceilings, 8 in. apart on

walls. For 1/4 in.-, 3/8 in.-,

and 1/2 in. -thick panels,

use 1-1/4 in. wallboard nails;

for 5/8 in. thick panels, use

1-3/8 in. wallboard nails.

Note: For outside corners,

lap panels to ensure a solid

backing for corner bead.

Avoid joints directly above

or below windows and

doors.

How to Attach Panels Screw Attachment

...Then Walls

Nail Attachment

Hold panels tight against

framing and fasten to studs

using conventional single

nail or screw application.

Apply the first nails or

screws approx. 7 in. from

the wall and at each joist.

Hammer nail until head is

seated in shallow dimple.

If nail breaks face paper,

drive in a second nail

2 in. from the first.

8