Service manual

www.enc.net.cn/en Tel/Fax:86-755-26984485/26985120 Appendix 1 EDS1100 Drawing machine Inverter Manual

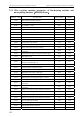

144

F2.35

Range 1 of retracting volume diameter

calculation

F2.34~F2.36 1 0.70 ○

F2.36 Range 2 of retracting volume diameter F2.35~F2.37 0.01V 1.20 ○

F2.37 Range 3 of retracting volume diameter F2.36~F2.38 1 1.70 ○

F2.38 Range 4 of retracting volume diameter F2.37~5.00V 0.01V 2.20 ○

F2.39 Smoothly start-up time 100~1500ms 1 2000 ○

F2.40 Start-up PID gain control

0:K2=F2.39

1:T<F2.39 K2=0

T>F2.39 K2=T/F2.44*F2.39

1 1 ○

F2.41 Smoothly start-up PID selection

0:PID

1:PD

1 1 ○

F2.42 Volume diameter reset control

0:Stop with automatically reset

1:X6 terminal manual reset

1 0 ○

F2.43

Wire disconnecting and delay PID

control

0:PID

1:PD

1 1 ○

F2.44 Time of wire disconnecting delay 0~32000Vms 1 5000 ○

F3-Closed-loop run function parameter group

Function

code

Name Set range Unit

Factory

default

Modificat

ion

F3.00

Closed-loop run control

selection

0:closed-loop run control ineffective

1:PI closed-loop run control effective

2:reserved

3:Special for drawing machine ――VCI

provision,

VCI ordinary PID closed-loop effective

4:Special for drawing machine――VCI

provision,VCI+PID closed-loop effective

5:Special for drawing machine――VCI

provision, feed forward control VCI+

PID closed-loop effective

1 0 ×

F3.08 Proportion gain KP 0.000-9.999 0.001 0.250 ○

F3.09 Integral gain KI 0.000-9.999 0.001 0.010 ○

F3.12 Deviation margin

0.0-20.0(%) percentage relative to max.value

of closed-loop provision

0.1(%) 1.0(%) ○

F3.20 PID proportion gain2 0.000~9.999 0.001 0.300 ×

F3.21 PID integral gain 2 0.000~9.999 0.001 0.000 ○

F3.22

ID Automatically

parameter adjustment basis

0:Only use the first PID parameter

1:Automatic adjustment base on volume

diameter(that is to select from two group

of PID parameters according to the place

of tension bar )

1 1 ○