Application

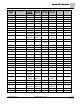

Table Of Contents

Sequence of Operation

Application Notes

12

Siemens Industry, Inc. Application Note, App 2521 140-1218

2015-05-06

– CLG FLOW MAX

5. Motor setup information may be incorrect. Check the values of the following points

and correct as needed:

– MTR SETUP

– MTR1 TIMING

– DMPR ROT ANG

6. The box may not have been balanced correctly. Contact your local Siemens

Industry representative.

7. The air velocity sensor may need calibration. Set CAL AIR to YES to run the

calibration sequence. When CAL AIR returns to NO, indicating that the sequence is

finished, run the checkout procedure again to see whether the problem has been

corrected.

Controller could not reach CLG FLOW MAX or above—CHK STATUS =

16

1. Check for the problems described immediately above for CLG FLOW MIN.

2. The box may be starved for air, because either the central air-handling unit is off or

there is low duct static.

Controller did not read low (zero) flow when damper closed—CHK

STATUS = 32

1. Check for the problems described above for CLG FLOW MIN.

2. The damper shaft may not be secured correctly to the actuator so that when the

actuator is fully closed, the damper does not completely shut off airflow.

3. Airflow calibration (at zero) may need to be performed ensuring the damper is fully

closed and/or the air handling unit is off.

Application Notes

If temperature swings in the room are excessive or there is trouble maintaining the

setpoint, the cooling loop must be tuned. If FLOW is oscillating while FLOW STPT

is constant, the flow loop requires tuning.

The controller, as shipped from the factory, keeps all associated equipment OFF.

For more information, contact your local Siemens Industry representative.