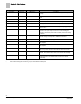

Operating Instructions

Chapter 3 – Point Database

19

Siemens Industry, Inc.

Owner's Manual

125-5084

06/30/2015

Descriptor

Address

1

Application

Description

DISCH TEMP

{84}

2930

Discharge temp sensor input.

GEX FLO STPT

{85}

2924, 2930

The desired value of the general exhaust. The controller

selects the lowest value that will lead to adequate supply flow,

and correct pressurization.

FAIL LIMIT

86

2924, 2930

Indicates when the air volume is too far away from setpoint.

CAL VENTURI

{87}

2924, 2930

Initiates and displays the initiation status of Venturi calibration.

VOL DIF STPT

{88}

2924, 2930

6754, 6760

The desired value for the flow difference. This value can be

selected and adjusted to achieve room pressurization.

OTHER EXH

{89}

2924, 2930

The value of any exhaust airflows not connected to the LCM.

Must be entered to the controller to account for flows it cannot

detect.

OCV ALM LVL

90

2924, 2930

Ventilation alarm level in occupied mode.

UCV ALM LVL

91

2924, 2930

Ventilation alarm level in unoccupied mode.

VENT ALM

{92}

2924, 2930

Alarm point indicates inadequate air change rate.

SUP FLO STPT

{93}

2924, 2930

The desired value of the supply flow, chosen by the controller,

to achieve the correct flow difference for the room.

CAL AIR

{94}

All

YES commands the controller to go through calibration

sequence for the air velocity transducers. YES is also displayed

when the calibration sequence is started automatically. CAL

AIR automatically returns to NO after the calibration sequence

is completed. Valid input: YES or NO.

CAL SETUP

95

2924, 2930, 2997

The configuration setup code for the calibration sequence

options.

CAL TIMER

96

2924, 2930, 2997

Time interval, in hours, between the calibration sequence

initiations if a timed calibration option is selected in CAL

SETUP.

SUPDUCT AREA

97

2924, 2930

Area, in square feet (square meters), of the supply duct where

the air velocity sensor is located. This value is calculated by the

field panel depending on duct shape and size. It is used in

calculating all points in units of cfm, CF, lps, and L.

DUCT AREA 1

97

2997

Area, in square feet (square meters), of the supply duct where

the air velocity sensor is located. This value is calculated by the

field panel depending on duct shape and size. It is used in

calculating all points in units of cfm, CF, lps, and L.

LOOP TIME

98

2924, 2930

The time, in seconds, between control loop calculations.

ERROR STATUS

{99}

All

The status code indicating any errors detected during controller

power up. A status of 0 indicates there are no problems.

SENSOR SEL

104

All

Room unit configuration point and thermistor type selection,

values are additive.

VENTURI ACT

105

2924, 2930

Setup point. Indicates NOPEN or NCLOSE for Venturi Air

Valves.

MODHTG FLO

106

2924, 2930

The minimum flow in feet per minute needed for safety

purposes when using electric reheat.

DO DIR.REV

107

All

Reverses the output state for selected non-motor digital

outputs.

RM RH

{108}

All

This point may be used in a control strategy as humidity levels

varies in the room being controlled.