Data Sheet for Product

Technical Specification Sheet

Document No. 149-320P25

August 10, 2021

Unrestricted

Siemens Industry, Inc.

Page 1 of 12

Laboratory Room Exhaust Air Terminal

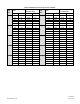

Figure 1. Laboratory Room Exhaust Air Terminal.

The Laboratory Room Exhaust Air Terminal is an

industrial grade, easy-to-install, pre-packaged

airflow measurement and control terminal unit.

When used with the Laboratory Room Controller, it

provides fast-acting, stable and precise laboratory

general exhaust airflow control over the entire range

of room airflow requirements.

Measurement of airflow is accomplished by unique

orifice plate or four quadrant sensing technology

that minimizes pressure loss and duct obstruction,

while maintaining measurement accuracy at 2% of

actual flow (sensor only). Airflow control uses a

round single blade damper. The terminal is

comprised of 22 gauge-galvanized steel including

the damper and orifice plate components. For

corrosive environments, 316L stainless steel or

Teflon® is available as an option. Slip or flange end

fitting connections may be selected to match the

ductwork construction. Flanges comply with the

SMACNA Round Industrial Duct Construction

Standard (RIDCS).

Features

• Orifice plate airflow measurement or four

quadrant airflow sensors with multipoint, center

averaging and signal amplification.

• Solid stainless steel damper shaft on Teflon

bushings for fast acting control and maintenance

free operation.

• Option of three different materials for

construction,

- Galvanized steel for non-corrosive, general

applications.

- 316L stainless steel for potentially corrosive

applications.

- Teflon for highly corrosive applications.

• Low non-recoverable static pressure loss.

• Eleven standard sizes with airflow capacities from

36 to 5591 cfm – additional sizes are available.

• Only two pivoting mechanical points, the damper

shaft ends in Teflon bushings are exposed to the

airstreams.

• Field commissionable and adjustable–not

dependent upon factory calibration.

• (Optional) Factory-mounted measurement and

control devices to simplify installation.

• Electronic or pneumatic damper control.

• Meets equipment requirements of ASHRAE 62.1

Sec. 5.

• LGE can be mounted in any orientation.

• Blade seals included as standard.

• Clean, sealed shipping bags available for LEED

IEQ projects.

• Lab DXR (IP & MSTP) control packages available