User's Manual Part 1

Table Of Contents

- Titel

- SIMATIC Sensors RFID systems SIMATIC RF300

- Legal Information

- Table of contents

- 1 Introduction

- 2 Safety information

- 3 System overview

- 4 RF300 system planning

- 4.1 Fundamentals of application planning

- 4.1.1 Selection criteria for SIMATIC RF300 components

- 4.1.2 Transmission window and read/write distance

- 4.1.3 Width of the transmission window

- 4.1.4 Impact of secondary fields

- 4.1.5 Permissible directions of motion of the transponder

- 4.1.6 Operation in static and dynamic mode

- 4.1.7 Dwell time of the transponder

- 4.1.8 Communication between communication module, reader (with IQ-Sense interface) and transponder

- 4.1.9 Calculation example (IQ-Sense)

- 4.1.10 Communication between communication module, reader (with RS422 interface) and transponder

- 4.1.11 Calculation example (RS422)

- 4.2 Field data for transponders, readers and antennas

- 4.3 Relationship between the volume of data and the transponder speed

- 4.4 Installation guidelines

- 4.5 Chemical resistance of the transponders

- 4.6 EMC Directives

- 4.1 Fundamentals of application planning

- 5 Readers

- 5.1 Overview

- 5.2 RF310R with IQ-Sense interface

- 5.2.1 Features

- 5.2.2 Pin assignment of RF310R IQ-Sense interface

- 5.2.3 Display elements of the RF310R reader with IQ-Sense interface

- 5.2.4 Ensuring reliable data exchange

- 5.2.5 Metal-free area

- 5.2.6 Minimum distance between RF310R readers

- 5.2.7 Technical data for RF310R reader with IQ-Sense interface

- 5.2.8 FCC information

- 5.2.9 Ordering data of RF310R with IQ-Sense interface

- 5.2.10 Dimension drawing

RF300 system planning

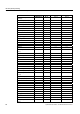

4.5 Chemical resistance of the transponders

SIMATIC RF300

70 System Manual, 09/2007, J31069 D0166-U001-A5-7618

Transponder RF380T

The housing of the heat-resistant data storage unit is made of polyphenylene sulfide (PPS).

The chemical resistance of the data storage unit is excellent. No solvent is known that can

dissolve the plastic at temperatures below 200 °C. A reduction in the mechanical properties

has been observed in aqueous solutions of hydrochloric acid (HCl) and nitric acid (HNO3) at

80 °C. The excellent resistance to all fuel types including methanol is a particular

characteristic. The following table provides an overview of the chemicals investigated.

Test conditions Substance

Time[days] Temperature[°C]

Evaluation

Acetone 180 55 +

n-Butanol (butyl alcohol) 180 80 +

Butanon-2 (methyl ethyl

ketone)

180 60 +

n-butyl acetate 180 80 +

Brake fluid 40 80 +

Calcium chloride (saturated) 40 80 +

Diesel fuel 180 80 +

Diethyl ether 40 23 +

Frigen 113 40 23 +

Anti-freeze 180 120 +

Kerosine 40 60 +

Methanol 180 60 +

Engine oil 40 80 +

Sodium chloride (saturated) 40 80 +

Sodium hydroxide (30%) 180 80 +

Sodium hypochlorite (5%) 30 80 /

180 80 –

Caustic soda (30%) 40 93 +

Nitric acid (10%) 40 23 +

Hydrochloric acid (10%) 40 80 –

Sulphuric acid (10%) 40 23 +

(10%) 40

(30%) 40

Tested fuels: 40 80 +

(FAM-DIN 51 604-A) 180 80 /

Toluene

1, 1, 1-trichloroethane 180 80 +

Xylene

Zinc chloride (saturated) 180 80 /

180 75 +

180 80 +

40 80 +