Operating Instructions

Optional Accessories

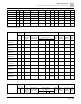

Brake Resistors and Brake Units Used in AC Motor Drives

390 | 443

RT001X-53N

1

0.75

0.5

80W 750Ω

BR080W750

1

-

1.2

280.0

4

4.5

RT002X-53N

2

1.5

1

200W 360Ω

BR200W360

1

-

2.6

186.7

6

6.7

RT003X-53N

3

2.2

1.5

300W 400Ω

BR300W400

1

-

2.3

160.0

7

7.8

RT005X-53N

5

3.7

2.5

500W 100Ω

BR500W100

1

-

9.2

93.3

12

13.4

RT0075-53N

7.5

5.5

3.7

750W 140Ω

BR750W140

1

-

6.6

80.0

14

15.7

RT010X-53N

10

7.5

5.1

1000W 75Ω

BR1K0W075

1

-

12.3

70.0

16

17.9

Table 18: 575V three-phase.

*1

Calculation for 125% brake torque: (kW)*125%*0.8; where 0.8 is motor efficiency. Due to the limited resistor

power, the longest operation time for 10% ED is 10 seconds (ON: 10 sec./OFF: 90 sec.).

*2

The brake resistor calculation is based on a four-pole motor (1800 rpm).

*3

For heat dissipation, a resistors of 400 W or lower should be fixed to the frame and maintain the surface

temperature below 4822°F (250°C); a resistor of 1000 W and above should maintain the surface

temperature below 662°F (350°C). (If the surface temperature is higher than the temperature limit, install

extra cooling or increase the size of the resistor.)

1. Select the resistance value, power and brake usage (ED%) per requirements.

2. Definition for Brake Usage ED%

3. For safety, install a thermal overload relay (OL) between the brake unit and the brake resistor in conjunction

with the magnetic contactor (MC) before the drive for additional protection. The thermal overload relay protects

the brake resistor from damage due to frequent or continuous braking. Under such circumstances, turn off the

power to prevent damage to the brake resistor, brake unit and drive.

NOTE: Never use it to disconnect the brake resistor.