Technical data

Chapter 9 – Communications

Siemens Building Technologies, Inc. 83

Analog Inputs – Use ANALOG IN 1 (Point 45) and Analog IN 2 (Point 46) to monitor the status

of the drives analog inputs (4 to 20 mA) from the field panel. For example, the chilled water

feedback could be sent to the field panel, calculations performed, and the chilled water valve

control command could be sent from the field panel through the drive and control the drive analog

output over ANALOG OUT 1 (Point 47).

Analog Outputs – Use ANALOG OUT 1 (Point 47) and ANALOG OUT 2 (Point 48) to control an

output (4 to 20 mA) from the field panel.

Loop gains – P GAIN (Point 61), I GAIN (Point 62), and D GAIN (Point 63) are gain parameters

similar to the P and I gains in the APOGEE TECs. The Siemens Building Technologies

representative must program the actual P and I gain constants through the SED2 drive.

Address limitations – Set CRLR ADDRESS (Point 1) to any value from 0 through 99. The

default value for this point is 99.

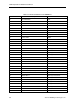

Table 8. Point Database for Application 2722.

Point

Number

Point

Type

Descriptor

Factory

Default

(SI Units)

Engr.

Units

(SI

Units)

Slope

(SI

Units)

Intercept

(SI Units)

On Text

Off

Text

01 LAO CTLR

ADDRESS

99 - 1 0 - -

02 LAO APPLICATION 2722 - 1 0 - -

{03} LAI FREQ

OUTPUT

0 HZ .04 -650 - -

{05} LAI SPEED 0 RPM 1 -16250 - -

{06} LAI CURRENT 0 A 0.5 0 - -

{07} LAI TORQUE 0 NM .02 -3250 - -

{08} LAI ACTUAL

POWER

0 HP/KW .01 0 - -

{09} LAI TOTAL KWH 0 KWH 1 0 - -

{13} LAI DC BUS VOLT 0 V 1 0 - -

{14} LAI REFERENCE 0 HZ .04 -650 - -

{16} LAI RATED PWR 0 HP/KW .01 0 - -

{17} LAI OUTPUT

VOLTS

0 V 1 0 - -

20 LAO OVRD TIME 1 HRS 1 0 - -

{21} LDI FWD.REV FWD - 1 0 REV FWD

{22} LDO CMD

FWD.REV

FWD - 1 0 REV FWD

{23} LDI STOP.RUN STOP - 1 0 RUN STOP

{24} LDO CMD

STP.STRT

STOP - 1 0 START STOP

{25} LDI AT MAX

FREQ

NO - 1 0 MAX NO