Instruction Manual

Table Of Contents

- TABLE OF CONTENTS

- tNTRODUCTtON

- SECTION I

- KNOW YOUR MACHINE - MODEL 2000 ATS

- SUPERLOCK SET UP & MAINTENANCE

- HINTS FOR SUCCESSFUL STITCHING

- Thread Selection

- NEEDLE REPLACEMENT

- NEEDLES, THREAD & FABRIC CHART

- SECTION II - THREADING & TENSION

- )

- NEEDLE THREADER

- HELPFUL HINTS - CHANGING THREAD

- TESTING STITCH

- THREAD TENSIONS

- ADJUSTING THREAD TENSION

- SUPERLOCK SEAMS & SEAM FINISH

- ADJUSTING STITCH LENGTH

- ADJUSTING CUTTING WIDTH & BALANCE OF STITCH

- ADJUSTING CUTTING WIDTH

- SECURING BEGINNING & END OF SEAM

- OUTSIDE CORNERS

- INSIDE CORNERS

- CORDED OVERLOOK

- RIBBING

- CASING OR HEM FOLD

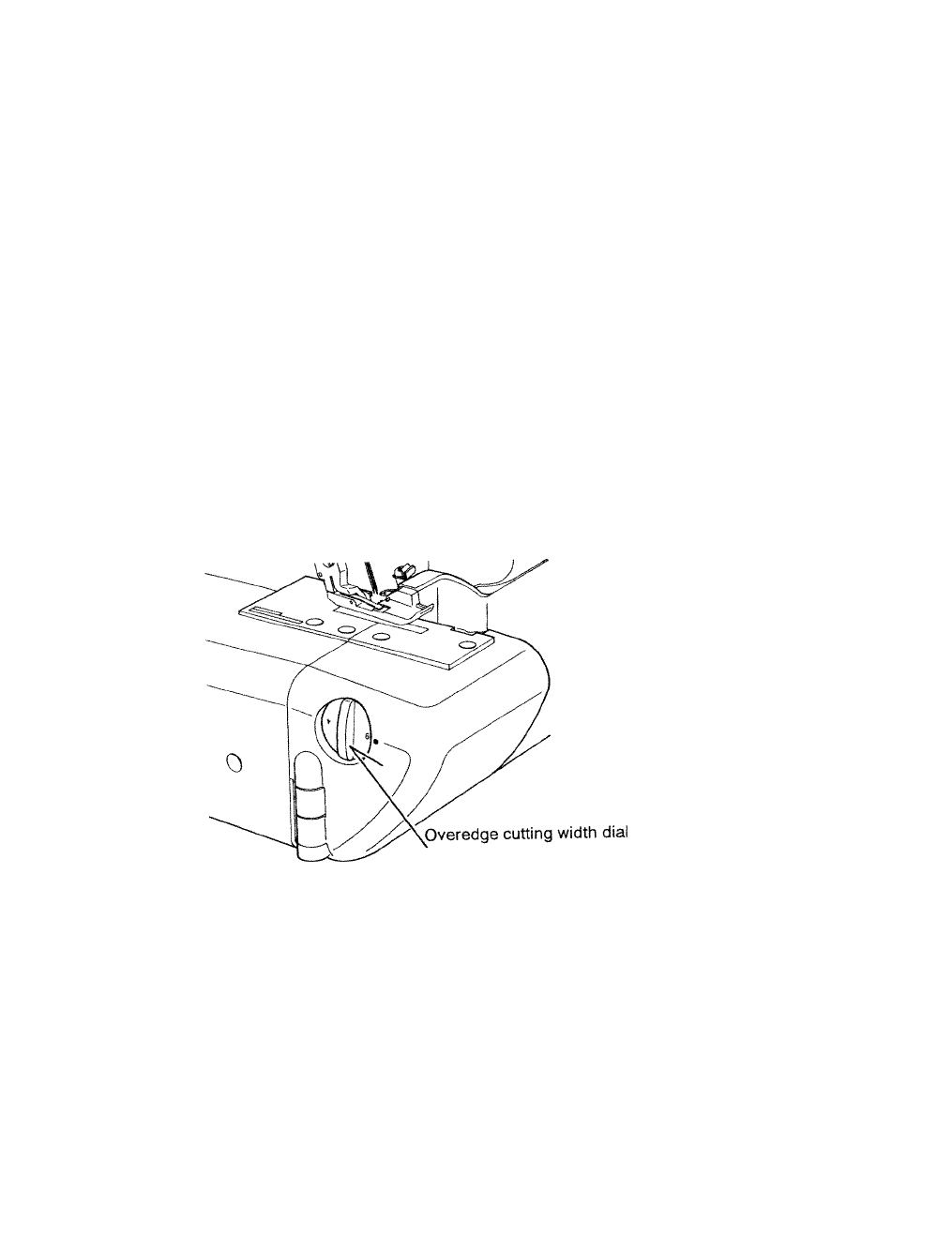

ADJUSTING CUTTING WIDTH &

BALANCE OF STITCH

The cutting width can be adjusted from 4mm to 7mm by simply turning the cutting

width dial according to the type of fabric you are working with. This fine tune adjustment

allows you to achieve the best stitch possible on all fabric types.

The normal setting for the cutting width is 6mm.

Adjust the cutting width by turning the dial on the left side of the Superlock. If the cutting

width is narrower than the stitch width, leaving loops off the edge of the fabric, turn the

cutting width adjustment dial toward 7.

If the cutting width is wider than the stitch width causing a pucker within the overlock

seam, turn the cutting width adjustment dial toward 4.

25