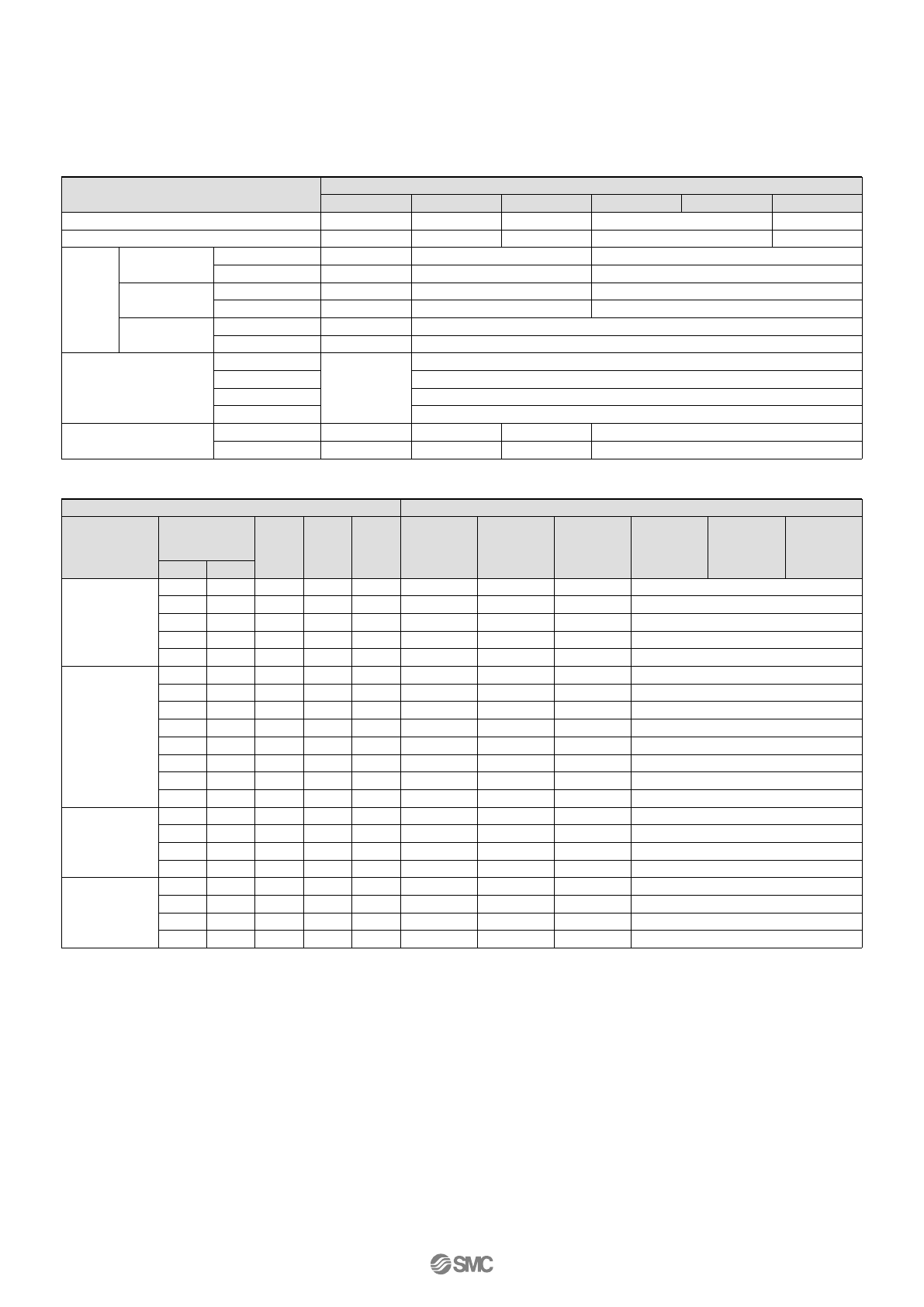

Datasheet

Options/Part No.

Model

Optional specifications

Bracket assembly

Note 1)

Set nut

Pressure

gauge

Digital pressure

Note 5)

switch

Float type auto drain

Round type

Note 2)

Standard

0.02 to 0.2 MPa setting

Standard

0.02 to 0.2 MPa setting

Standard

0.02 to 0.2 MPa setting

N.C.

N.O.

NPN output / Wiring bottom entry

NPN output / Wiring top entry

PNP output / Wiring bottom entry

PNP output / Wiring top entry

Square embedded

type

Note 4)

Round type

Note 2)

(with colour zone)

AR10P-270AS

AR10P-260S

G27-10-R1

G27-10-R1

Note 3)

—

—

—

—

AW10(K)

AW20P-270AS

AR20P-260S

AD17

—

—

AD27

—

AW20(K)

AR30P-270AS

AR30P-260S

AD37

AD38

AW30(K)

AR40P-270AS

AR40P-260S

AW40(K)

G46-10-02

G46-2-02

G46-10-02-L

G46-2-02-L

AD47

AD48

GC3-10AS [GC3P-010AS (Pressure gauge cover only)]

GC3-2AS [GC3P-010AS (Pressure gauge cover only)]

ISE35-N-25-MLA [ISE35-N-25-M (Switch body only)]

ISE35-R-25-MLA [ISE35-R-25-M (Switch body only)]

ISE35-N-65-MLA [ISE35-N-65-M (Switch body only)]

ISE35-R-65-MLA [ISE35-R-65-M (Switch body only)]

G36-10-01

G36-2-01

G36-10-01-L

G36-2-01-L

AW40(K)-06

AW60P-270AS

Note 6)

—

Note 7)

AW60(K)

Semi-standard/Bowl Assembly Part No.

Note 1) Assembly includes a bracket and set nuts

Note 2)

in part numbers for a round pressure gauge indicates a type of connection thread. No indication is necessary for R; however, indicate N for NPT. Please contact SMC

regarding the connection thread NPT and pressure gauge supply for psi unit specifications.

Note 3) Standard pressure gauge

Note 4) Including one O-ring and 2 mounting screws. [ ]: Pressure gauge cover only

Note 5) Lead wire with connector (2 m), adapter, lock pin, O-ring (1 pc.), mounting screw (2 pcs.) are attached. [ ]: Switch body only. Also, regarding how to order the digital pressure

switch, please refer to page 89. A pressure switch adapter assembly (AW60P-310AS) will be additionally required for the AW60(K) only. Use the attached mounting screw (M3

x 0.5 x 14) for mounting. The mounting screw (M3 x 0.5 x 7) attached to the digital pressure switch assembly will not be required.

Note 6) Assembly of a bracket and 2 mounting screws

Note 7) Please consult SMC regarding the set nuts for the AW60(K).

Note 8) Minimum operating pressure: N.O. type–0.1 MPa; N.C. type–0.1 MPa (AD27) and 0.15 MPa (AD37/47). Please contact SMC for psi and

°F unit specifications.

Note 9) Please consult SMC for details on drain piping to fit NPT or G port sizes.

Note) • Bowl O-ring is included for the AW20(K) to AW60(K).

• Bowl assembly for the AW30(K) to AW60(K) models comes with a bowl guard (steel band material). (except when the bowl material is metal)

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

C1SF-6

—

AD17-6

—

—

—

—

—

C1SF-2

AD17-2

—

—

—

—

—

—

N.C. N.O.

Model

Semi-standard

specifications

With

bowl

guard

With

barb

fitting

Bowl material

Polycarbonate

Nylon

Metal

Metal bowl with

level gauge

AW40(K)-06

AW40(K)AW30(K)AW20(K)AW10(K)

C2SF-C

AD27-C

C2SF-J

—

C2SF-CJ

C2SF-6

C2SF-6C

AD27-6

—

AD27-6C

C2SF-6J

—

C2SF-6CJ

C2SF-2

AD27-2

—

C2SF-2J

—

—

—

—

—

—

C3SF-J

C3SF-W

—

C3SF-6

—

AD37-6

AD38-6

—

C3SF-6J

C3SF-6W

—

C3SF-2

AD37-2

AD38-2

C3SF-2J

C3LF-8

AD37-8

AD38-8

C3LF-8J

—

—

C4SF-J

C4SF-W

—

C4SF-6

—

AD47-6

AD48-6

—

C4SF-6J

C4SF-6W

—

C4SF-2

AD47-2

AD48-2

C4SF-2J

C4LF-8

AD47-8

AD48-8

C4LF-8J

AW60(K)

With

drain

guide

Note 9)

Float type

auto drain

Note 8) Note 9)

Note 8) Note 9)

Series AW10 to AW60

Series AW20K to AW60K

Orange mark

Selection

1. Residual pressure disposal (outlet pressure removal) is not

possible for the AW20 to AW60 even though the inlet pressure

is exhausted. When the residual pressure disposal is perfor-

med, use the filter regulator with backflow function (AW20K to

AW60K).

Warning

Maintenance

1. Replace the element every 2 years or when the pressure drop

becomes 0.1 MPa, whichever comes first, to prevent damage

to the element.

Warning

Mounting and Adjustment

1. Set the regulator while verifying the displayed values of the in-

let and outlet pressure gauges. Turning the regulator knob ex-

cessively can cause damage to the internal parts.

2. The pressure gauge included with regulators for 0.02 to 0.2

MPa setting is for up to 0.2 MPa use only (except the AW10).

Exceeding 0.2 MPa of pressure can damage the gauge.

3. Do not use tools on the pressure regulator knob as this may

cause damage. It must be operated manually.

1. Be sure to unlock the knob before adjusting the pressure and

lock it after setting the pressure. Failure to follow this procedu-

re can cause damage to the knob and the outlet pressure may

fluctuate.

• Pull the pressure regulator knob to unlock. (You can visually

verify this with the “orange mark” that appears in the gap.)

• Push the pressure regulator knob to lock. When the knob is

not easily locked, turn it left and right a little and then push it

(when the knob is locked, the “orange mark”, i.e., the gap will

disappear).

2. A knob cover is available to prevent careless operation of the

knob. Refer to page 90 for details.

Caution

Warning

Series AW10 to AW60

Series AW20K to AW60K

Specific Product Precautions

Be sure to read this before handling. Refer to “Precautions for Handling Pneumatic

Devices” (M-03-E3A) for Safety Instructions and F.R.L. Units Precautions.

69