Datasheet

Design

Warning

1. Warning concerning abnormal outlet pressure

• If there is a likelihood of causing an outlet pressure drop

due to unforeseen circumstances such as equipment

malfunction, thus leading to a major problem, take safety

measures on the system side.

• Because the outlet pressure could exceed its set range if

there is a large fluctuation in the inlet pressure, leading to

unexpected accidents, take safety measures against abnor-

mal pressures.

• Operate the equipment within its maximum operating

pressure and set pressure range.

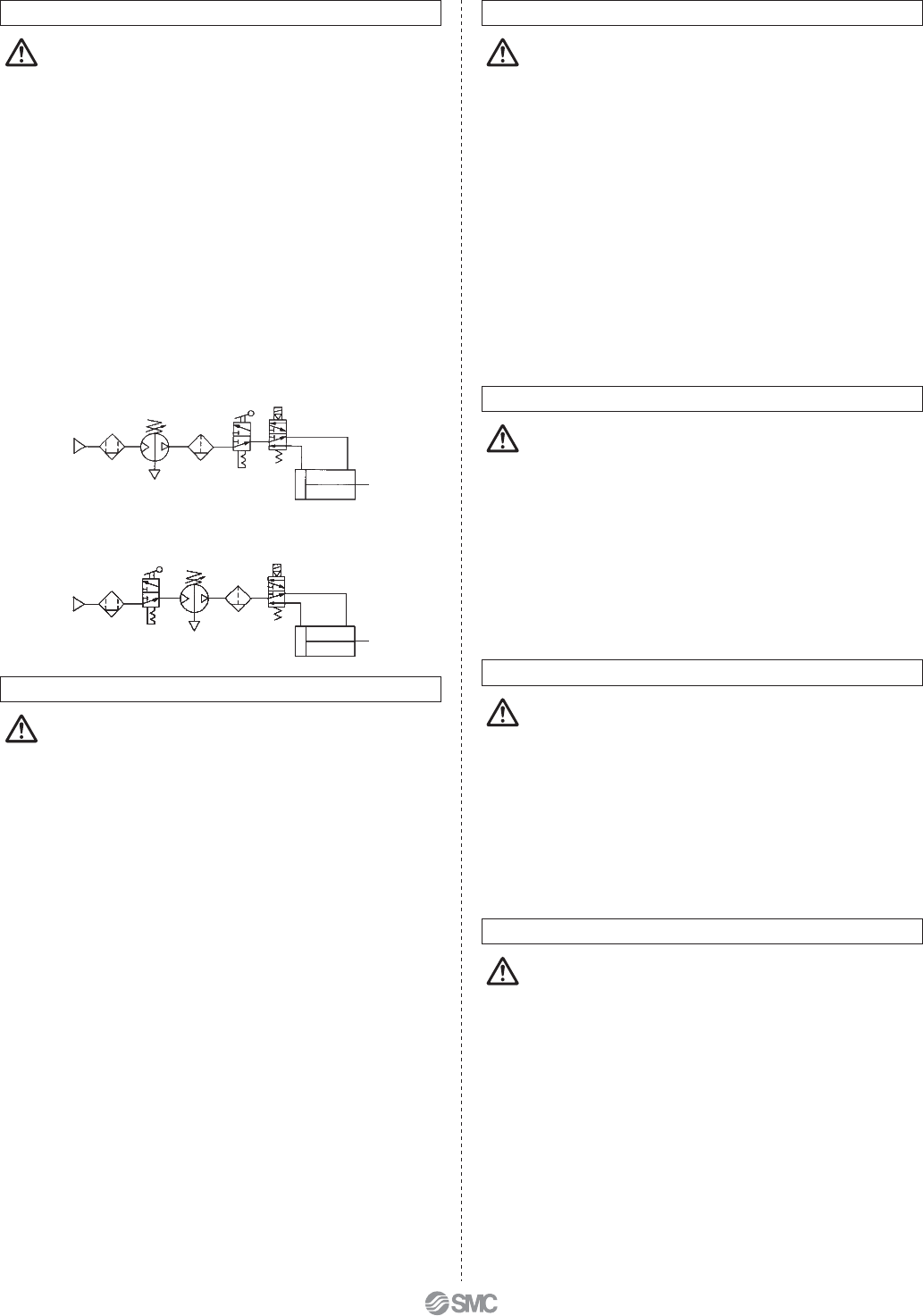

2. Residual pressure measures

• Connect a 3-port valve to the OUT side of the booster

regulator if the residual pressure must be released quickly

from the outlet pressure side for maintenance, etc. (Refer to

the diagram below.) The residual outlet pressure side

cannot be released even if the 3-port valve is connected to

the IN side because the check valve in the booster regulator

will activate.

• After operation is finished, release the supply pressure at

the inlet. This stops the booster regulator from moving

needlessly and prevents operating malfunctions.

Selection

Caution

1. Check the specifications.

• Consider the operating conditions and operate this product

within the specification range that is described in this

catalogue.

2. Selection

•

Based on the conditions (such as pressure, flow rate and cycle time) required for

the outlet side of the booster regulator, check the selection procedures described

in this catalog or model selection software for size selection of the booster

regulator.

•

Since the booster regulator is a compressor powered by the air, it consumes the

air. The air consumption is approximately 1.2 times (pressure increase ratio 2) or

2.7 times (pressure increase ratio 4) larger than the outlet side volume.

Therefore, the booster regulator requires a supply capacity of the inlet side

volume that is approximately 2.2 times (pressure increase ratio 2) or 3.7 times

(pressure increase ratio 4) larger than the outlet side volume.

•

Set the pressure of the VBA10A, VBA20A, VBA22A, VBA40A, VBA42A or

VBA43A (pressure increase ratio 2) to a level that is at least 0.1 MPa higher than

the inlet pressure. If the pressure differential is 0.1 MPa or less, the internal

operating pressure becomes the minimum operating pressure or less and the

switching valve may remain at the intermediate position, causing a restart failure.

•

Set the pressure increase ratio of the VBA11A (pressure increase ratio 4) to 2 or

more. When the VBA11A is used at a pressure increase ratio of 2 or less, the

internal operating pressure becomes the minimum operating pressure or less and

the switching valve may remain at the intermediate position, causing a restart

failure.

•

When operating the booster regulator continuously for longer periods of time,

particularly confirm its service life.

•

The service life of the booster regulator depends on not the operation hours but

the operating cycles (piston sliding distance). The operating cycles (piston sliding

distance) depend on the outlet flow of the booster regulator. Thus, when more

outlet flow of the booster regulator is used, its service life becomes shorter.

Mounting

Caution

1. Transporting

• When transporting this product, hold it lengthwise with both

hands. Never hold it by the black handle that protrudes from

the center because the handle could become detached

from the body, causing the body to fall and leading to injury.

2. Installation

• Install this product so that the silver-coloured tie-rods and

cover are placed horizontally. If mounted vertically, it may

result in a malfunction.

• Because the piston cycle vibration is transferred, use the

following mounting bolts (VBA1: M5; VBA2, 4: M10) and

tighten them with the specified torque (VBA1: 3 N·m; VBA2,

4: 24 N·m).

• If the transmission of vibration is not preferred, insert an

isolating rubber material before installation.

• Mount the pressure gauge with a torque of 7 to 9 N·m.

Piping

Caution

1. Flushing

• Use an air blower to flush the piping to thoroughly remove

any cutting chips, cutting oil, or debris from the piping

inside, before connecting them. If they enter the inside of

the booster regulator, they could cause the booster regula-

tor to malfunction or its durability could be affected.

2. Piping size

• To bring the booster regulator’s ability into full play, make

sure to match the piping size to the port size.

Air Supply

Caution

1. Quality of air source

• Connect a mist separator to the inlet side near the booster

regulator. If the quality of the compressed air is not

thoroughly controlled, the booster regulator could malfunc-

tion (without being able to boost) or its durability could be

affected.

• If dry air (atmospheric pressure dew point: –17°C or less) is

used, the life expectancy may be shortened because dry air

will accelerate evaporation of grease inside.

Operating Environment

Caution

1. Installation location

• Do not install this product in an area that is exposed to

rainwater or direct sunlight.

• Do not install in locations influenced by vibrations. If it must

be used in such an area due to unavoidable circumstances,

please contact SMC beforehand.

Series VBA

7