Datasheet

Handling

1

0.9

0.8

0.7

0.6

0.5

0.5

0.4

0.4

0.3

0.3

0.2

0.2

Pilot pressure MPa

0.1

0.1

0

Outlet pressure MPa (Q = 0)

SMC

HighLow

1. Setting the pressure on the handle-operated type

• If air is supplied to the product in the shipped state, the air

will be released.

Set the pressure by quickly pulling up on the governor

handle, releasing the lock, and rotating the handle in the

direction of the arrow (+).

• There is an upper and lower limit for the handle rotation. If

over-rotating the handle even after reaching to the limit, the

internal parts may be damaged. If the handle suddenly feels

heavy while being turned, stop turning the handle.

• Once the setting is completed, push the handle down and

lock it.

• To decrease the outlet pressure, after the pressure has

been set, rotate the handle in the direction of the arrow (–).

The residual air will be released from the area of the

handle, due to the relief construction of the governor.

• To reset the pressure, first reduce the pressure so that it is

lower than the desired pressure; then, set it to the desired

pressure.

Caution

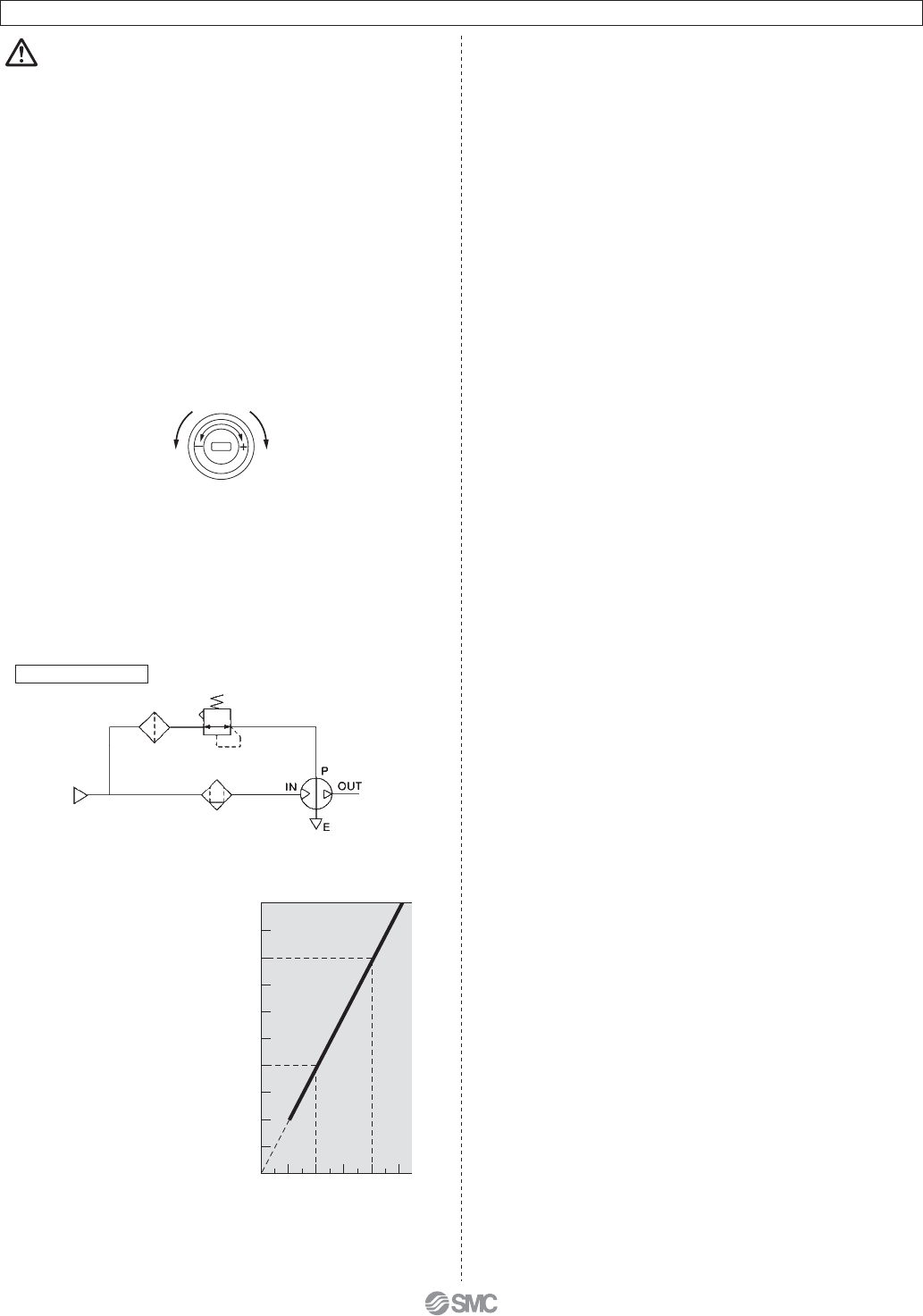

2. Setting the pressure on the air-operated type

(VBA22A, 42A)

• Connect the outlet pipe of the pilot regulator for the remote

control to the pilot port (P). (Refer to the diagram below.)

• Refer to the graph below for the relationship between the

pilot pressure and outlet pressure.

• The AR20 and AW20 are recommended for the pilot regula-

tor.

Pilot regulator

• The outlet pressure is twice the pilot pressure.

• When the inlet pressure is 0.4 MPa:

Pilot pressure

0.2 MPa to 0.4 MPa

Outlet pressure

0.4 MPa to 0.8 MPa

3. Draining

• If this product is used with a large amount of drainage

accumulated in the filter, mist separator or tank, the

drainage could flow out, leading to equipment malfunction.

Therefore, drain the system once a day. If it is equipped

with an auto drain, check its operation once a day.

4. Exhaust

• Exhausting time from E port may be longer for a booster

regulator which is set to switch in longer hour intervals. This

is not an abnormal phenomenon.

5. Maintenance

• Life expectancy varies depending on the quality of air and

the operating conditions. Signs that the unit is reaching the

end of its service life include the following:

•

Constant bleed from under the handle.

•

Air exhaust noise can be heard from the booster regulator

at 10 to 20 second intervals even when there is no air

consumption on the outlet side.

Conduct maintenance earlier than scheduled in such cases.

• When maintenance is required, confirm the model and lot

number of the booster regulator, and please contact SMC

for maintenance kit.

• Conduct maintenance according to the specified mainte-

nance procedure by individuals possessing enough knowl-

edge and experiences in maintaining pneumatic equipment.

• The list of replacement parts and kit number are shown on

page 9, and the figure shows the position of the parts.

Booster Regulator Series VBA

8