Datasheet

Specifications

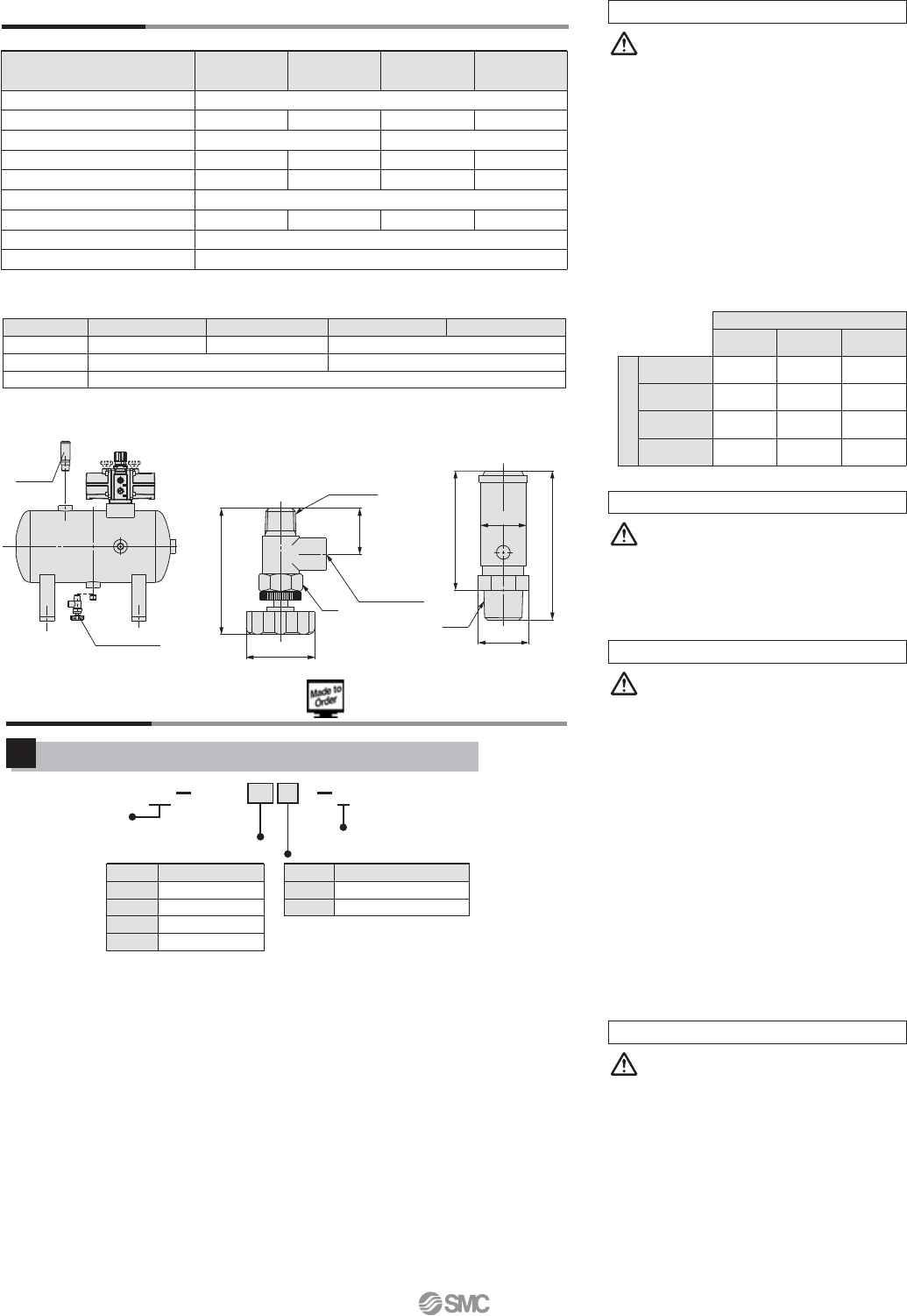

Booster regulator

VBA2쏔AVBA1쏔A VBA4쏔A

쎲

쎲

—

—

쎲

쎲

쎲

쎲

쎲

—

—

—

1. Operating pressure

• Operate this product below the maximum operat-

ing pressure. If it is necessary, take appropriate

safety measures to ensure that the maximum op-

erating pressure is not exceeded.

• When the tank alone is used

Use a pressure switch or a safety valve to ensure

that the maximum operating pressure is not ex-

ceeded.

2. Connection

• Connect a filter or a mist separator to the OUT

side of the tank. Because the inner surface of the

tank is untreated, there is a possibility of dust

flowing out to the outlet side.

• A VBA booster regulator can be connected

directly with the tank accessories as indicated

combinations below.

• Consider the operating conditions and operate

this product within the specification range.

• When using the air tank with a booster regulator,

refer to “Sizing” on page 5 or SMC Pneumatic

System Energy Saving Program.

Warning

Caution

Design

Selection

Caution

1. Accessories

• Refer to the operation manual (VBAT-M1, M2,

M3, M4) regarding combining booster regulators

with older model air tanks.

• The accessories are secured by bands to the feet

of the air tank. Once removed, make sure not to

lose them.

2. Installation

• Install the tank away from people. It is dangerous

if the accumulated air inside the tank were to

seep out.

• Do not mount the air tank on a moving part or a

place with vibration.

• When connecting a booster regulator with the

tank, refer to the operation manual first, which is

provided with the air tank before assembling.

• Refer to the operation manual regarding mount-

ing methods when using long bolts.

• To mount the air tank on a floor surface, use the

four holes to secure the tank with bolts or anchor

bolts.

Mounting

Warning

1. Inspection

• The use of pressure vessels could lead to an un-

expected accident due to external damage or

internal corrosion caused by drainage. Therefore,

make sure to check periodically for external

damage, or the extent of internal corrosion

through the port hole. An ultrasonic thickness

indicator may also be used to check for any re-

duction in material thickness.

2. Draining

• If this product is used with a large amount of

drainage, the drainage could flow out, leading to

equipment malfunction or corrosion inside the

tank. Therefore, drain the system once a day.

Maintenance

VBAT05A

VBAT10A

VBAT20A

VBAT38A

Model

VBAT05A

쏔-SV-Q

VBAT10A

쏔-SV-Q

VBAT20A

쏔-RV-Q

VBAT38A

쏔-SV-Q

Fluid

Tank capacity (L)

Max. operating pressure

(MPa)

IN port size

OUT port size

Ambient and fluid temperature

(°C)

Weight (kg)

Material

Paint

5

3/8

3/8

6.6

10

1/2

1/2

10

20

3/4

1/2

14

38

3/4

3/4

21

Compressed air

0 to 75

Carbon steel (SS400)

Outside: Silver paint, Inside: Rustproof paint

2.0 1.0

Note) The accessories and options are included in the same container.

Air tank

Drain valve

IN PORT

1/4

19

OUT PORT

1/8

20

ø30

58 (CLOSE) to

63 (OPEN)

52

65

3/8

19

ø18.5

Safety

valve

Safety valve

VBAT-R, VBAT-S∗

Drain valve VBAT-V1∗

Copper-free/Fluorine-free

1

Note 1) The thread type for each port is Rc.

Note 2) A stainless steel fitting and a drain valve are included in the

same container as accessories. (For detailed dimensions,

please contact SMC.) A safety valve cannot be selected.

Note 3) Since neither copper nor fluorine parts are used for the

tank, a standard model can be used when options (safety

valve and drain valve) are not necessary.

20 1VBAT V

Made to Order

Copper-free/

Fluorine-free

Made to Order

Material

Carbon steel (SS400)

Stainless steel 304

Material

With drain valve

Symbol

A

S

Internal capacity

5 L

10 L

20 L

38 L

Tank internal

capacity

Symbol

05

10

20

38

A10

For detailed dimensions, specifications

and lead times, please contact SMC.

Model

VBAT05A쏔-SV-Q

VBAT10A쏔-SV-Q VBAT20A쏔-RV-Q VBAT38A쏔-RV-Q

Accessory kit

Safety valve

Drain valve

VBAT5A-Y-2

VBAT-S (Set pressure: 2 MPa)

VBAT-V1

VBAT10A-Y-2 VBAT20A-Y-2

VBAT-R (Set pressure: 1 MPa)

Series VBAT

13