Datasheet

General line (low pressure) Locations requiring high pressure

VBA

VBA

VBA VBA

(Two-stage

pressure boost)

P2

P1

Shortening time

Without check

valve by-pass

Time t (S)

Outlet pressure (MPa)

P2

P1

0

Plant line (source pressure)

Operating pressure:

0.5 MPa

Bore size: ø100

Output ≈ 3850 N

Operating pressure:

0.8 MPa

Bore size: ø80

Output ≈ 4000 N

0.5 MPa

ø100

IN 0.5 MPa

E

ø80

OUT 0.8 MPa

Equivalent

output

VBA22A, 42A

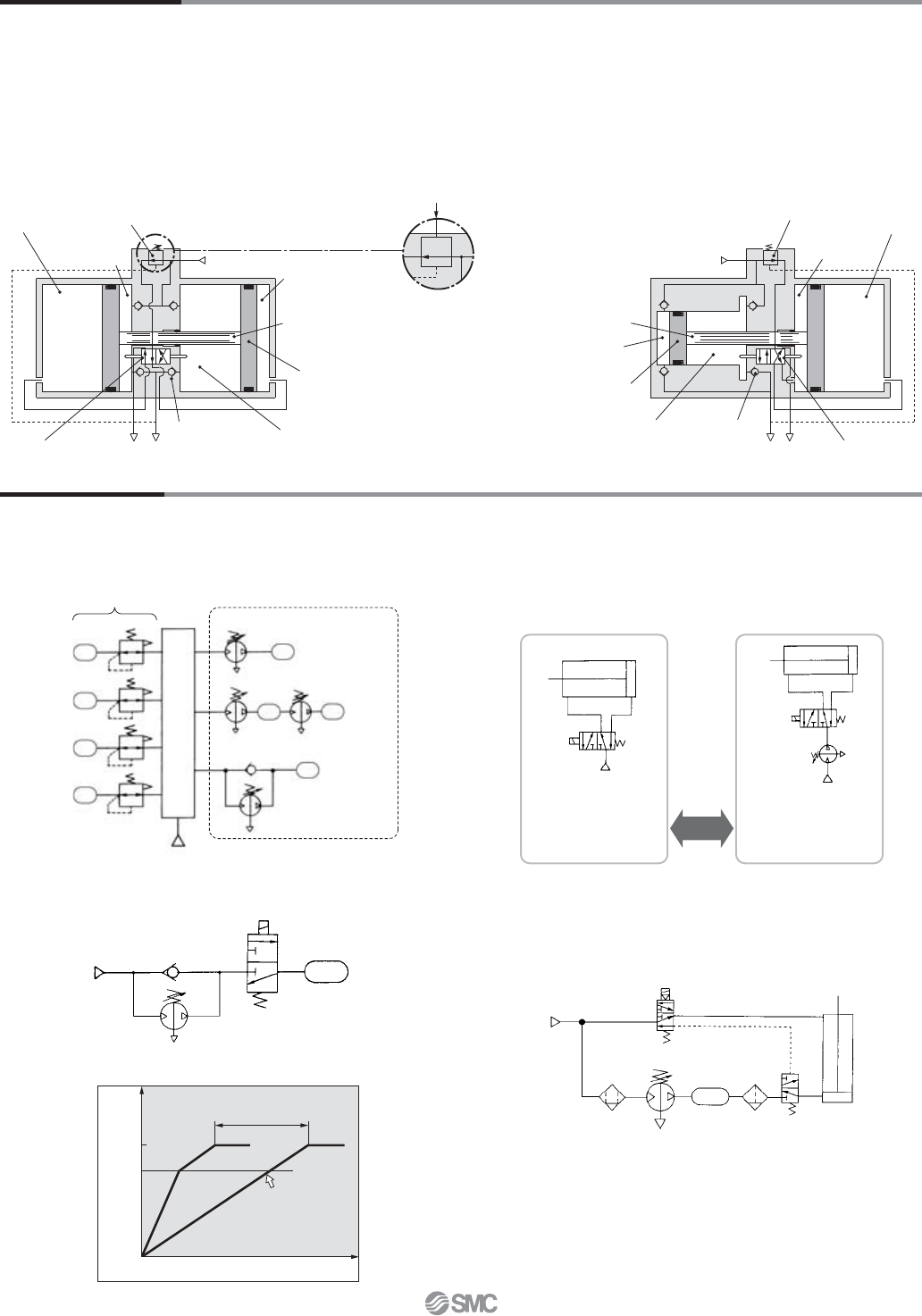

Air-operated type

Pilot pressure

IN (Inlet)

Governor

Booster

chamber A

Drive

chamber A

Switching valve

Piston

Drive chamber B

Booster chamber B

Check valve

OUT (Outlet)

E

Piston rod

Governor

Drive

chamber B

Drive

chamber A

Switching valve

EOUT (Outlet)

Check valveBooster

chamber B

Piston

Booster

chamber A

Piston rod

IN (Inlet)

Circuit Example

Working Principle

The IN air passes through the check valve to booster chambers A and B. Meanwhile, air is supplied to drive chamber B via the governor and

the switching valve. Then, the air pressure from drive chamber B and booster chamber A are applied to the piston, boosting the air in booster

chamber B. As the piston travels, the boosted air is pushed via the check valve to the OUT side. When the piston reaches to the end, the piston

causes the switching valve to switch, so that drive chamber B is in the exhaust state and drive chamber A is in the supply state respectively.

Then, the piston reverses its movement, this time, the pressures from booster chamber B and drive chamber A boosts the air in booster

chamber A and sends it to the OUT side. The process described above is repeated to continuously supply highly pressurized air from the IN to

the OUT side. The governor establishes the outlet pressure by handle operation and pressure adjustment in the drive chamber by feeding back

the outlet pressure.

VBA10A, 20A, 40A, 43A

Initially, inlet pressure (P1) passes through the check valve, fills P2,

and results in P1 = P2.

VBA11A

• When only some of the machines in the plant require high-pressure

air, booster regulators can be installed for only the equipment that

requires it. This allows the overall system to use low-pressure air

while accommodating machines requiring high-pressure air.

• When the actuator output is insufficient but space limitations prohibit

switching to a larger cylinder diameter, a booster regulator can be

used to increase the pressure. This makes it possible to boost the

output without replacing the actuator.

• When a certain level of output is required but the cylinder size must

be kept small so that the driver remains compact.

• When charging a tank or the like from a source at atmospheric

pressure, a circuit with a check valve can be used to reduce the

charge time by allowing air to pass through the check valve up to

the inlet pressure.

• When only one side of the cylinder is used for work, booster

regulators can be installed only on the lines that require them to

reduce the overall air consumption volume.

Booster Regulator Series VBA

6