Technical Specifications

SQUARE.

SUPERIOR.

STRONGER.

STAMP HERE

“The original patented

plastic, Square footing form

with a unique U.S. method’s patent for simultaneous

forming of concrete footings and piers.”

Toll Free 1 877 924-2323

Tel (802) 764-2323

Fax (802) 872-0707

www.soundfootings.com

www.tubebase.com

TM

37 Talcott Road

P.O. BOX 818

Williston, VT 05495

Made in the U.S.A

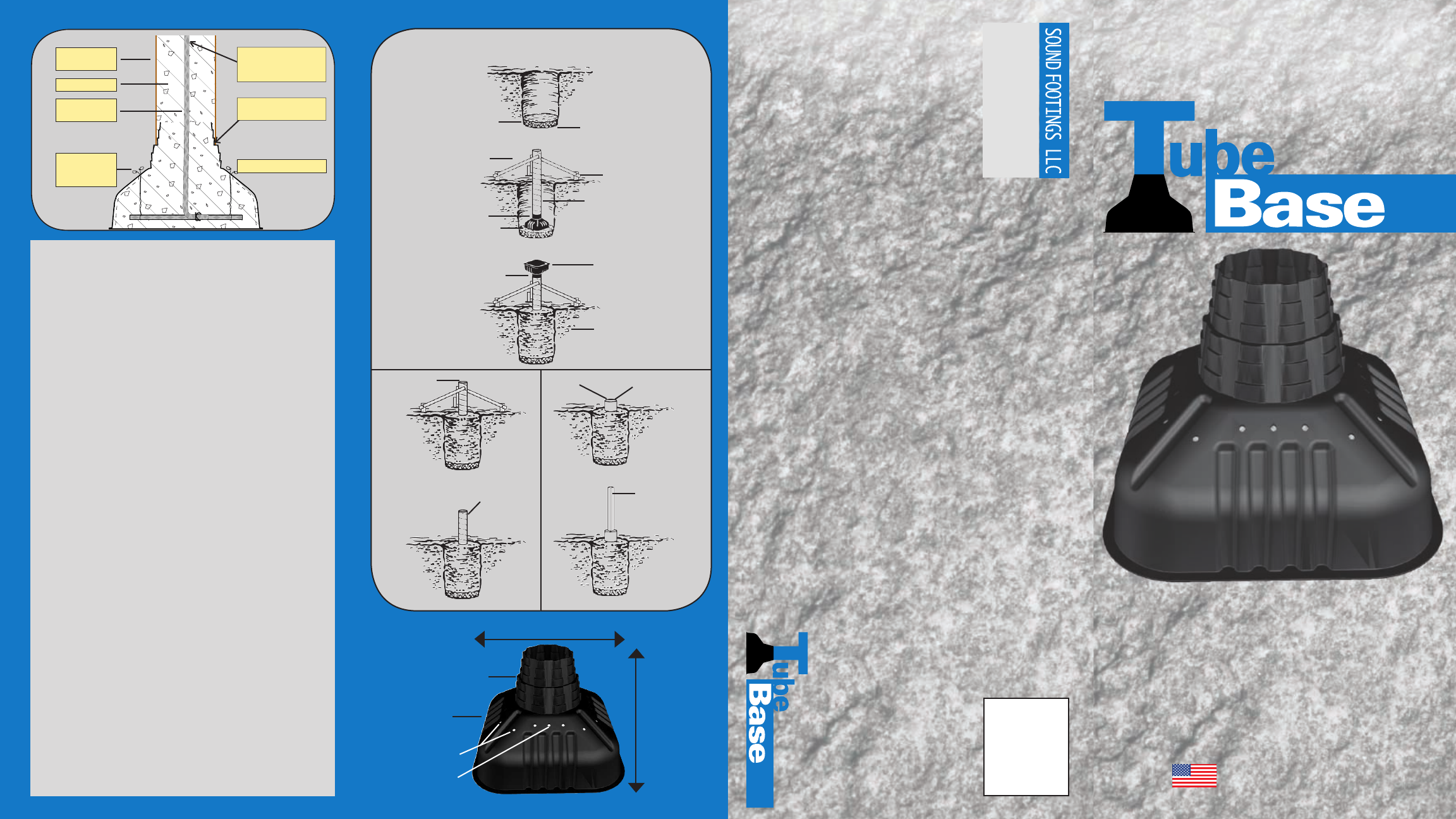

Below Grade/Ground Installation Tips

1. Excavate hole to a depth to avoid frost penetrating under

pier (Typically 4’ to 6’).

2. Apply Construction Tube to TubeBase

™

footing form.

3. Cut off excess plastic at top of wedges to desired

Construction Tube size.

4. Attach Construction Tube to TubeBase

™

footing form with

a minimum of 4 1” Screws.

5. Place TubeBase

™

footing form at desired location. (On

undisturbed soil or 4”-6” of compacted crushed stone or

gravel)

6. Install footing rebar if required. (See example)

(Rebar installation should be approved and designed

by a qualified Engineer and meet all Building Code

requirements.)

7. Level/Plumb Construction Tube/TubeBase

™

footing form

prior to backfilling.

8. Construction Tube and TubeBase

™

footing form combined

cannot exceed/extend 24” or more above grade/ground.

(See our website for Above Ground Tech Tips)

9. Have inspected by Building Inspector as required by

different municipalities.

10. Backfill making sure Construction Tube remains level/

plumbed at desired location.

11. Prior to pouring concrete into Construction Tube invert

spare TubeBase

™

on top of Construction Tube to act as a

funnel for concrete pour.

12. Pour concrete.

13. Install anchor bolt to accept bracket as required.

IMPORTANT: See our website for Below Grade/Ground

Technical Tips

Above Grade/Ground Installation Tips

1. For any TubeBase

™

footing form project which requires

the combined use of a Construction Tube and TubeBase

™

footing form to exceed/extend 24” above ground/grade

when pouring concrete, the Construction Tube MUST be

braced to prevent movement of Construction Tube while

the concrete is curing. (Conventional methods: Strapping

or 2X Materials w/Stakes; Wooden Collar; Frame with Side

Braces)

IMPORTANT: See our website for Above Grade/Ground

Technical Tips

www.tubebase.com or www.soundfootings.com

Rebar* (if

necessary)

Concrete

Construction

Tube

TubeBase

™

2 Rebar Tie

“Holes” on

all 4 corners

*Use of Structural

Steel should be

approved &

designed by a

qualied engineer

Made in the U.S.A

Dig/Excavate

Hole/Trench

4” - 6” Crushed Stone

Undisturbed Soil

Braces

Stakes

Qty 4 1” Screws

TubeBase™

Construction Tube

Top of Concrete

Inverted

TubeBase

as funnel for

concrete pour

Back Fill

Concrete

Top of Concrete

Anchor Bolts

Apply 4X4 or

other uses

Strip C. Tube

TubeBase™ V1 22

22” (56 cm)

TubeBase™ V1 32

32” (81 cm)

16.6” (42 cm)

21.1” (54 cm)

TM

TubeBase™ V1 22

TubeBase™ V1 32

>

>

>

>

>

>

Wedge system accommodates

all small, medium and large

construction tubes

Ribs for structural

integrity

>

Rebar ties on

each corner

Installation Tips / Cross Section

Air Vent Holes

>

>

Center rebar in

place as concrete

is poured

Cut cone to size of

Construction Tube