Full Product Manual

Table Of Contents

- Contents

- Overview

- Ring Terminals

- Flag Terminals

- Fork Terminals

- Pin Terminals

- Splice Connectors

- Wire Joints

- Heat-Shrinkable Terminals, Splices, Disconnects

- Disconnects and Male Tabs

- Luminaire Disconnects

- Ferrules

- Wire Termination Tools and Installation Kits

- Wire Termination Technical Information

- Shrink-Kon® Heat-Shrinkable Tubing

- Shrink-Kon® Splice Insulatorsand Insulating Covers

- Shrink-Kon® Installation Tools

- Shield-Kon® Shield Termination System

- Dragon-Tooth® Magnet WireTermination System

United States

Tel: 901.252.8000

800.816.7809

Fax: 901.252.1354

Technical Services

Tel: 888.862.3289

www.tnb.com

G-89

Shield-Kon

®

Shield Termination System

Wire Termination — Sta-Kon

®

Wire Termination & Insulation

The design advantages are:

• Positive selection of inner and outer sleeves and installing

die by a complete color-coded system

• A more reliable grounding termination because only

one ground wire connection is made — conventional

daisychain jumper method is eliminated

• Smaller, more compact bundle is easy to inspect

• Only one ground wire is required; however, additional

ground wires may be used if needed

• Smooth insulator protects conductor insulation

• With one stroke of the tool, the interlace die will produce

a 360° compression, uniformly securing all individual

shields around the connector

The Shield-Kon

®

Connector System for multiple-conductor shielded cable is

based on the principle of cold swaging. It utilizes a two-piece compression

connector color coded to match the proper die. The connector consists of

ahard brass collector inner ring with a tough, smooth insulator and a soft

copper compression outer ring. Each set of rings and matching installing

diewill connect a minimum of five shielding braids with one ground wire.

The maximum number of braids is limited only by the space between the

inner and outer rings.

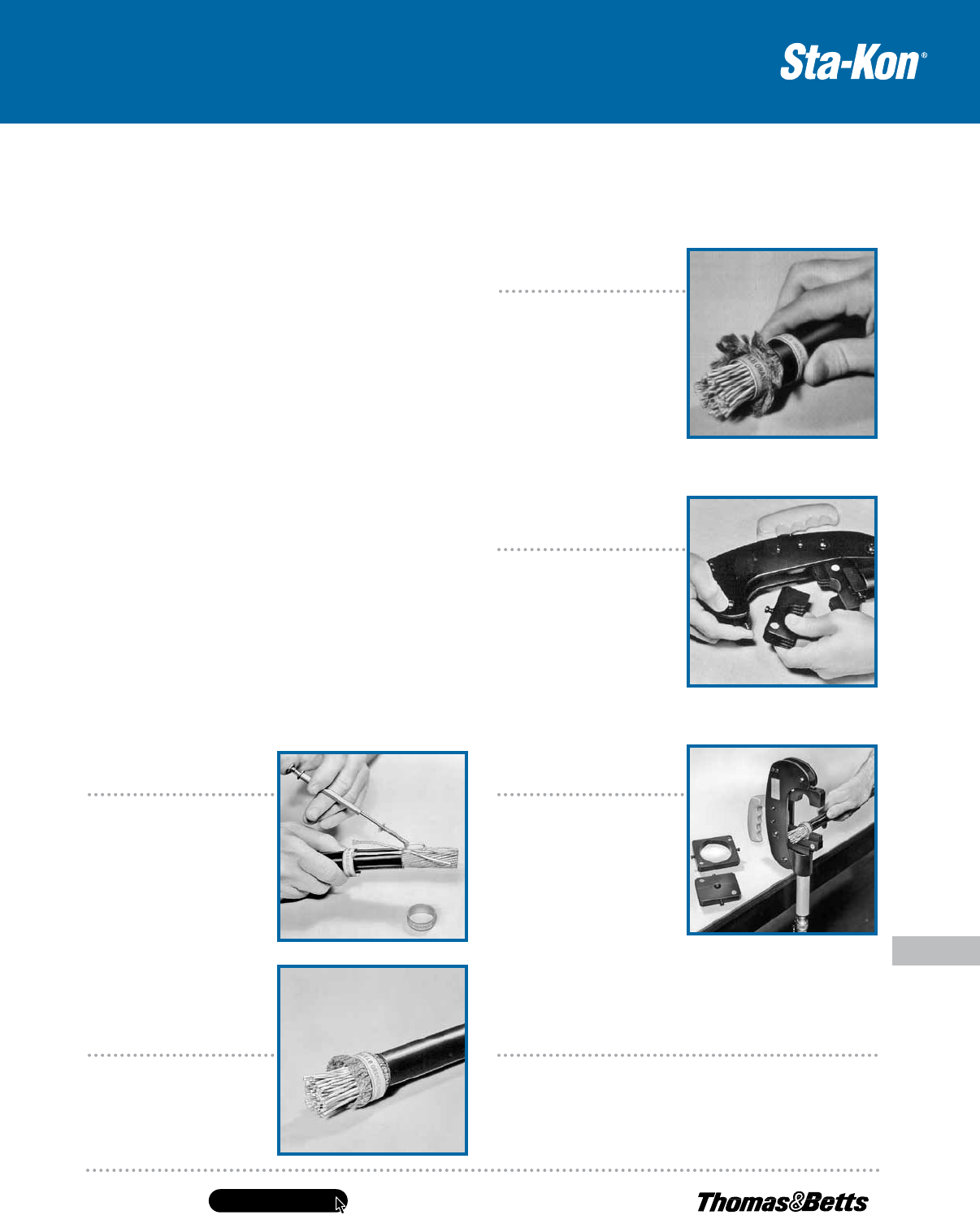

Step 1

After overall insulation is removed

to expose shielded cables, each

conductor must befreed from the

shielding braid. TheThomas &

Betts lead extractor toolsimplifies

this operation by pushing theinner

conductor through an opening

in theshielding braid. The braid

is then folded back until all

conductors are freed.

Step 2

Flattened shielding braids

areevenly distributed around

theperiphery of the inner

collectorring.

Step 3

Position outer compression

ringover the flattened shielding

braid, locating it over the center of

the inner collector ring. Braidmay

be trimmed even with the edge of

the outer compression ring before

or after compression. Ground wire

or wires may be inserted between

the outer compression ring and

the shield prior tocompression.

Step 4

Selection of compression dies

isdetermined by color coding

on rings. The dies are color

coded tomatch the rings. The

appropriate dies are easily inserted

or removed bydepressing die-

locking button shown.

Step 5

The prepared cable is placed

in the installing die and compressed.

Tool operates on hydraulic power

output, developing 9800 ±200 psi

operating pressure.

Step 6

Completed installation of the “single fold–fold forward” method typifies

the reliability, compactness and neatness that is obtained with all

Thomas & Betts recommended installation methods.

Multi-Shielded Cable Connector

Installation Procedure

Terminate multiple-conductor shielded

cable quickly and easily!