User guide

28

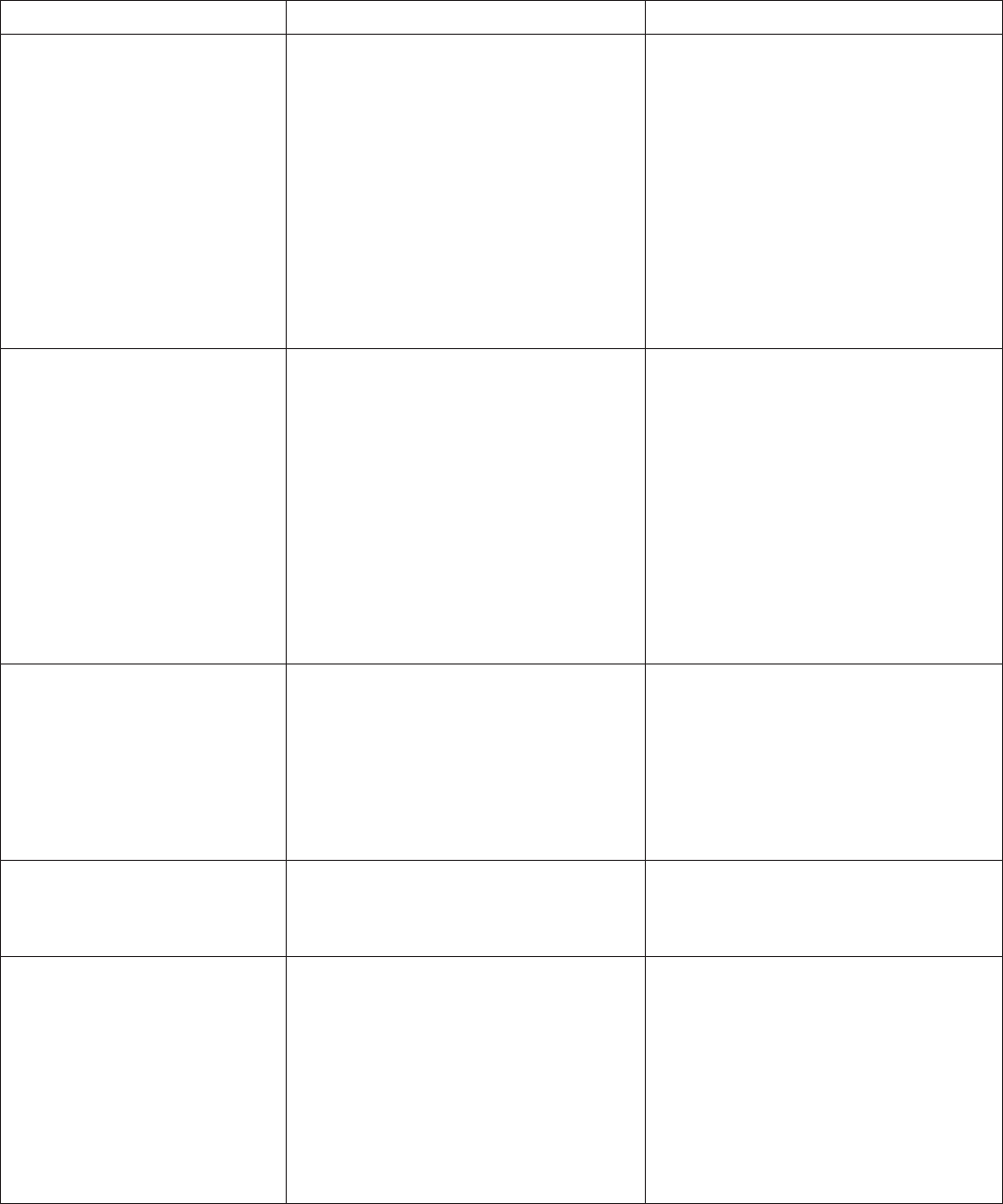

Table 9 - Separated Combustion Tubular Blower Troubleshooting Guide (continued)

SYMPTOMS POSSIBLE CAUSE(S) CORRECTIVE ACTION

N. Not enough heat. 1. Incorrect gas input.

2. Heater undersized.

3. Thermostat malfunction.

4. Heater cycling on limit.

5. Incorrect orifi ce sizes.

1. Refer to "Gas Input Rate"

2. Is the heater output sized correctly for the

heat loss of the space? Has the space been

enlarged? Is the heater located in the space

properly (see "Installation")?

3. Check thermostat circuit; 24V on terminals

"R" and "W" on terminal strip.

4. Check air movement across heat exchanger.

Check voltage and amps at the blower motor.

Check gas input to ensure unit is not over

fi red. Check heat exchanger to ensure unit is

not dirty.

5. Check orifi ce size (Refer to "Gas Input Rate"),

replace if necessary.

O. Too much heat. 1. Unit is over fi red.

2. Thermostat malfunction.

3. Heater runs continuously.

4. Defective gas valve.

5. Excessive gas supply pressure.

6. Excessive static pressure.

1. Refer to "Gas Input Rate." Check orifi ce size.

Replace if too large.

2. Check thermostat for operation, to ensure

circuit open and closes.

3. Check wiring per diagram. Check operation at

the gas valve. Look for a short in thermostat

circuit.

4. Replace valve and check pressure setting

(See Table 4 "Gas Piping Requirements").

5. Refer to "Pipe Installation" and Table 4 - "Gas

Piping Requirements."

6. Adjust blower sheave to correct RPM - See

"Blower Set Up and Adjustment."

P. Noisy blower/motor. 1. Blower wheel loose.

2. Blower wheel is dirty.

3. Blower wheel is rubbing on housing.

4. Bearings are dry.

5. Pulley is loose.

1. Replace or tighten.

2. Clean blower wheel.

3. Realign blower wheel.

4. Oil bearings on blower motor. (Refer to label

on motor.)

5. Check Blower and Motor pulleys. Replace or

tighten as necessary.

Q. Cold air is delivered during heater

operation.

1. Incorrect manifold pressure or input.

2. Air throughput too high.

1. Test and reset manifold pressure (see Table

4 - "Gas Piping Requirements").

2. Check Blower and Motor pulleys. Replace or

tighten as necessary.

R. High limit is tripping. 1. Unit is over fi red.

2. Air fl ow is too low.

3. Defective high limit.

4. Defective control board.

1. Refer to "Gas Input Rate." Check orifi ce size.

Replace if too large.

2. Check for proper voltage; ensure blower

assembly is correct.

3. Check operation of switch. If switch is open

during operation, check gas pressure and/

or CFM; adjust accordingly. If switch is open

during start-up, replace switch.

4. Check for 24V on line side of high limit.

Constant voltage should be recorded. If not,

control board is suspect. Check fl ash code.