user manual

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 23

ASSEMBLY INSTRUCTIONS/OPERATIONS

5) Turn the height adjustment lever clockwise to

lower the blade into the crack until the desired

sawing depth is achieved. Each full turn of the crank

lever will raise/lower the blade approximately 1/16

inch.

6) Following the random crack direction and/or

pattern with the blade is accomplished by viewing

the blade and crack in the louvered opening in the

blade guard. The louvers are intended to provide

protection for the operator in the event that a

diamond segment becomes separated from the

blade blank. Probable causes for such occurrences

are discussed in detail in the Troubleshooting

section of this manual.

a) The geometric design of the louvered blade guard

is intended to provide a high mathematical

percentage of protection for the operator in a normal

operating position as described in this manual. The

mathematical percentage will decrease for operating

positions not described in this manual.

b) In the event of diamond segment separation from

the blade blank, there is a high mathematical

probability that the segment will be thrown forward

against the dust pan located under the main frame

or directly against the forward (non louvered) section

of the blade guard. The manufacturer has

conducted extensive testing to substantiate this

theory. In actual field tests, diamond segments were

purposely separated from the blade blanks through

abusive operational techniques. In all field tests, no

separated diamond segments made direct contact

with the blade guard louvers.

c) In the very low probability that a diamond

segment would make direct contact with the blade

guard louvers, the geometric design has a high

mathematical probability to not allow the segment to

penetrate the vertical plane as defined by the

location of the louvers. The spaces, angle

orientation and number of louvers minimize the

mathematical probability that a segment can

penetrate the vertical plane, exit the louvers and

eventually strike the operator.

d) The geometric configuration of the louvers are

designed to allow for adequate and/or proper

visibility for the operator during the sawing process.

With use, concrete and/or asphalt dust will

accumulate at the bottom of the blade guard

opening. At regular intervals, this material should be

removed to enhance operator visibility during the

sawing process.

DANGER

DO NOT MODIFY THE ORIGINAL OPERATING

CONFIGURATION FOR THE LOUVERS FOR ANY

REASON. MODIFICATIONS TO THE LOUVERS

CAN RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

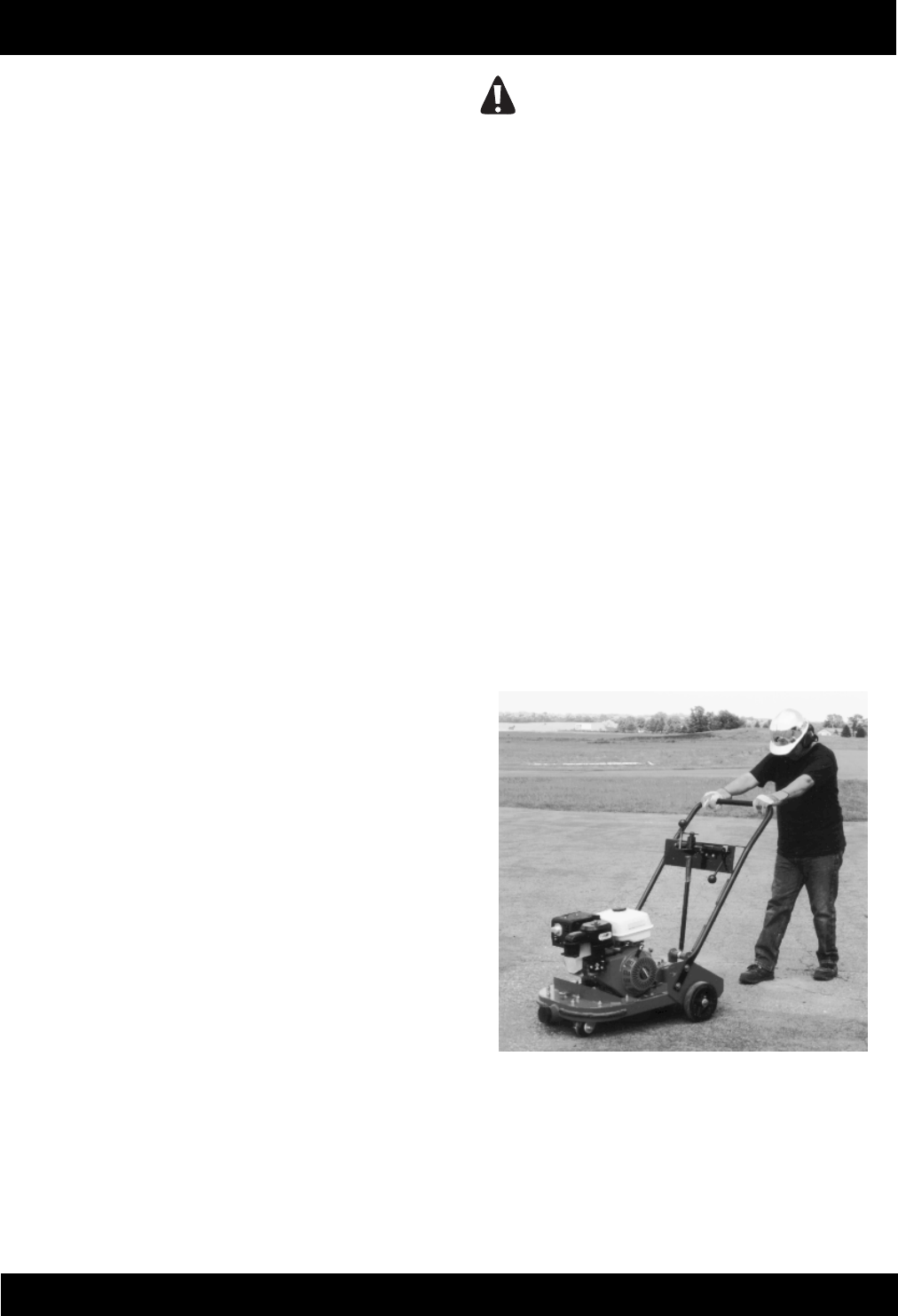

7) Proper operator posture and stance will enhance

operational safety and overall productivity. FIGURE

24 depicts a proper operator's position. FIGURE 25

depicts an improper operator's position that can

accelerate fatigue, decrease productivity and reduce

safety. The downcut orientation of the diamond

blade will normally produce a "self-propelled" effect

against the operator. This effect is intended to

reduce the operator fatigue associated with the

operation of the machine and to increase overall

productivity.

8) In some operating conditions, it may be

necessary for the operator to apply a resisting force

(push) against the operator handle to counteract the

"self-propelled effect. In some other operating

conditions, it may be necessary for the operator to

apply a force (pull with) to the operator handle in

order to assist the sawing action of the Crack Saw.

FIGURE 24