User's Manual

REPLACING THE WIRE ROPE

Replace damaged wire rope with

the manufacturer’s recommended

replacement part or a factory

approved equivalent identical in

strength, quality, lay, and stranding.

Pass the attaching end of wire rope

through the fairlead and attach it

to the drum. When inserting the

wire rope into the drum, insert it

into the correct end of the hole

provided (See Figure 8). Tighten the

set screw securely.

It is important that the wire rope be

wound tightly onto the drum.

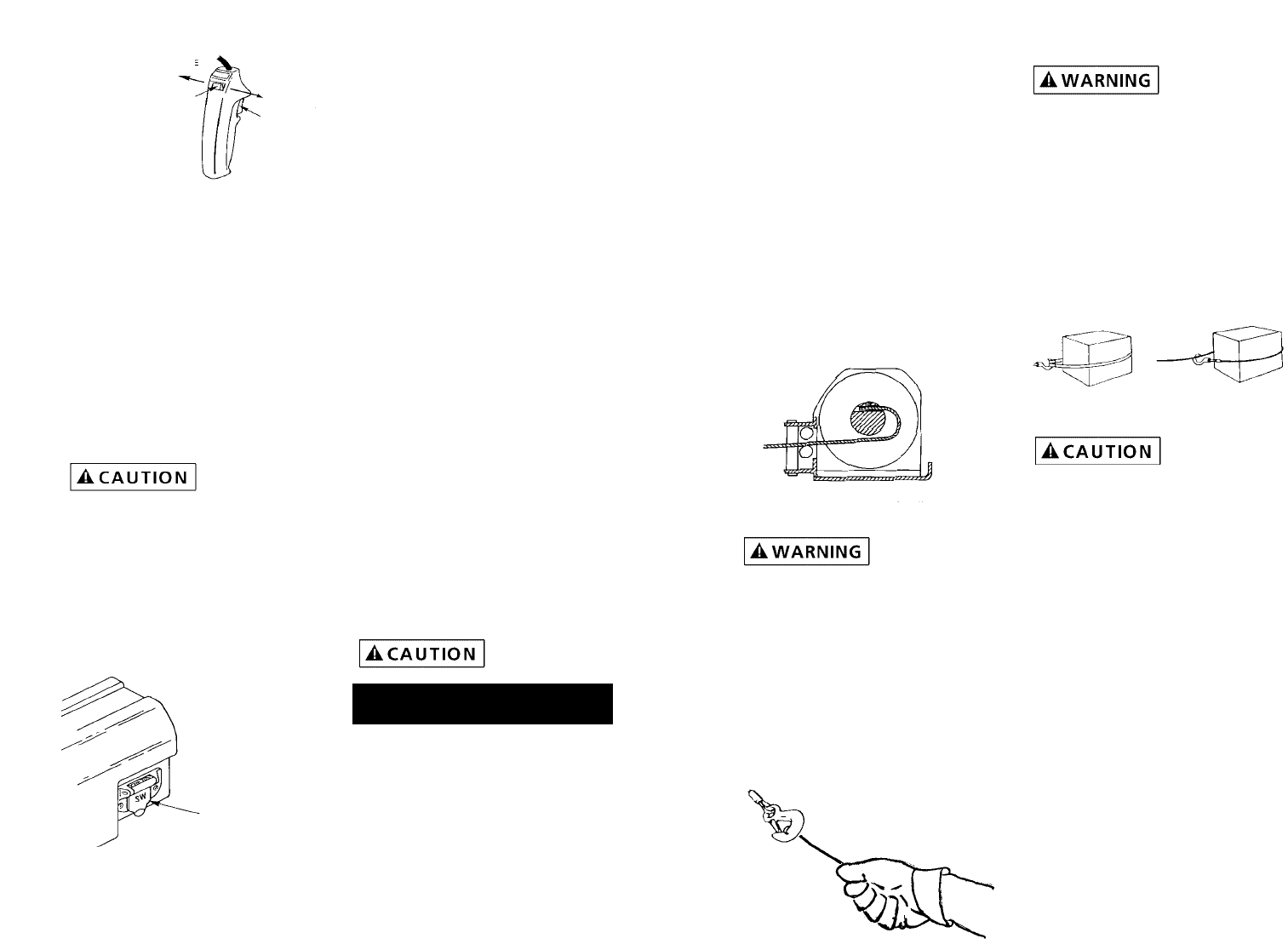

HANDLING THE WIRE ROPE

Use heavy

leather gloves

when handling wire rope. Do not

allow wire rope to slide through

hands.

1. Never winch with less than 5

turns of wire rope around winch

drum, since wire rope and fasten-

er may not withstand the load.

ALWAYS USE HANDSAVER BAR

WHEN GUIDING HOOK FOR THE

LAST FEW FEET OF ROPE

(See Figure 9)

Keep clear of

winch wire rope

and hook when operating winch.

Never put your finger through the-

hook. Placing finger(s) in hook

could result in injury.

2. Never hook wire rope back onto

itself. Hooking wire rope onto

itself can damage rope. Use a

nylon sling (See Figure 10). When

using a sling, make sure that sling

is properly seated in saddle of

hook.

Avoid continu-

ous pulls from

extreme angles. This will cause wire

rope to pile up at one end of drum.

This can jam wire rope in winch

causing damage to rope or winch

itself.

3. Do not use wire rope as a ground

for welding.

4. Never touch welding electrode to

wire rope.

5. Keep wire rope tight and even on

drum.

6. Replace wire rope when frayed.

TIPS FOR EXTENDING THE LIFE OF

YOUR WINCH

1. Keep a tightly wound wire rope

drum. Do not allow the wire rope

to become loosely wound. A

loosely-wound drum allows a

wire rope under load to work its

way down into the layers of wire

rope on the drum. When this

happens, the wire rope may

become wedged within the body

of the windings, damaging the

10

11

PENDANT OPERATION

The switch trigger returns to the

“OFF” position when released (See

Figure 6, Ref. A). The slide button

on the back of the switch deter-

mines the direction of the drum

rotation for lowering or lifting a

load (See Figure 6, Ref. B). The slide

is fitted with an interlock so that

the motor cannot be reversed if the

trigger is depressed. To change

direction, release the trigger, move

the slide button, and depress the

trigger again.

The switch

assembly must

be kept free of dirt and moisture to

ensure safe operation.

To connect the pendant control, lift

the dust cover on the plug recep-

tacle (See Figure 7), and insert the

plug end of the remote switch. The

plug on the pendant control cord is

keyed and will fit into the socket

only one way.

Do not allow winch motor to over-

heat. The winch is for intermittent

use only. During long or heavy pulls

the motor will get hot. Allow to

cool after 2 minutes of “ON” time.

MAINTENANCE AND REPAIR

Periodically check tightness of

mounting bolts and electrical con-

nections. Remove any dirt or corro-

sion that may have accumulated on

the electrical connections.

BRAKE OPERATION

Your winch has a wrap spring brake

that stops and holds loads up to

1,000 lb. (454 kg). When the winch

is powered out, as in releasing a

load, the brake is engaged and the

motor must overpower the brake

resistance to rotate the drum.

Therefore, it is normal for the

winch to operate faster in one

direction than the other. The brake

is designed for the wire rope to be

used in the underwind position

only. Drum must turn counterclock-

wise, looking from motor end,

when winching in.

DO NOT

OVERWIND.

Powering against the

brake will cause heat to build up in

the drum and may transfer heat to

the wire rope. DO NOT POWER OUT

FOR MORE THAN 2 MINUTES.

The drum may

get very hot.

WIRE ROPE

For safety reasons, it is important

that you use a wire rope with a

break strength of at least 5,600 lbs.

Recommended wire rope for this

winch will have a 1/4" diameter

with a 7 x 19 construction, and a

minimum break strength of 7,000

lbs. or a 7/32" diameter with 7 x 19

construction, with a minimum break

strength of 5,600 lbs.

Figure 10

Right

Wrong

OPERATION

Figure 6

POWER

OUT

POWER

IN

A

B

Figure 7

DUST

COVER

Figure 8

Figure 9