UserManual S SA2 S SA2L202010

Table Of Contents

- Table of Contents

- Introduction

- Warnings

- Operating Conditions

- Installation

- Installation Methods

- Opening Preparation for S-SA2 Installation

- Standard Distances Between Damper Bodies

-  Installation into a Soft Crossing (up to Size 1000 × 800 mm)

- Connecting S-SA2 to “multi” Ductwork Made of Boards

- S-SA2L Installation

-  Installation on the Vertical Duct with a Ledge

-  Installation Directly on the Horizontal Duct

- Electrical Connections

- Operation Manual

- Smoke Damper Functionality Check

- Smoke Damper Inspection

- Warranty Conditions

- Operating Journal

- Warranty Service

S-SA2L

L1V

22/40 | User Manual S-SA2 & S-SA2L | 201905

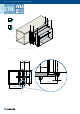

1. Prepare the duct connection or opening as per Fig. 36 - Fig. 41, clean and atten the connecting surface.

2. Apply a re resistive coat (3) on the connection surfaces as depicted in Fig. 36 - Fig. 41.

3. Connect the damper’s ange (on the blade side) to the duct as per the

“Fixing the S-SA2L Smoke Damper”

section.

4. From boards (4 and 7) create a collar overlapping the connection as depicted in Fig. 36 - Fig. 41.

5. Fix the overlapping collar to the damper with screws (5). Fix the collar to the duct by using screws

as per instructions of duct system manufacturer.

IMPORTANT: The opening dimensions must be created according to the details of each type and thickness

of the connected duct.

The re resistivity of the S-SA2L smoke damper must be decreased to the duct performance.

The maximum resistivity for L1V installation is EI120S with pressure level 3 (-1500 Pa … 500 Pa).

1 Smoke damper S-SA2L (actuator side)

2 Connected ductwork classied according EN 1366-9

3 Fire resistive coating Promat K84 (Promat)

4 Collar made of Promatect H (Promat) - thickness per detail

5 Screw 5,5×40 DIN 7981 xing the collar with the damper

6 Screws or pins as per duct system manufacturer instructions

7 Cover plates thickness 10 mm placed on the opening circumference made of Promatect H (Promat)

8 Combi screw size 8

9 Accessory K1-S-SA2L-W×H (size of damper = W - nominal width; H - nominal height)

Damper‘s horizontal blade axis orientation

Damper‘s vertical blade axis orientation

Legend for Figures of Installation

Installation on the Vertical Duct with a Ledge