Datasheet

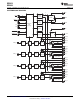

GVDD

GVDD

PVDD

PVDD

M

M

Controller

RESET_AB

PWM_B

OC_ADJ

GND

GND_A

GND_B

OUT_B

PVDD_B

AGND

VREG

M3

M2

BST_B

BST_C

PVDD_C

OUT_C

RESET_CD

PWM_D

VDD

GVDD_C

OUT_D

PVDD_D

BST_D

GVDD_D

PWM_C

GND_D

M1

GND_C

GVDD_B

OTW

FAULT

PWM_A

GVDD_A

BST_A

PVDD_A

OUT_A

DRV8412

DRV8432

www.ti.com

SLES242C –DECEMBER 2009–REVISED MAY 2010

Dual Full Bridge PWM Motor Driver

Check for Samples: DRV8412, DRV8432

The DRV8412/32 require two power supplies, one at

1

FEATURES

12 V for GVDD and VDD, and another up to 50 V for

• High-Efficiency Power Stage (up to 97%) with

PVDD. The DRV8412/32 can operate at up to

Low R

DS(on)

MOSFETs (80 mΩ at T

J

= 25°C)

500-kHz switching frequency while still maintain

• Operating Supply Voltage up to 50 V

precise control and high efficiency. They also have an

(70 V Absolute Maximum)

innovative protection system safeguarding the device

against a wide range of fault conditions that could

• DRV8412 (power pad down): up to 2 x 3 A

damage the system. These safeguards are

Continuous Output Current (2 x 6 A Peak) in

short-circuit protection, overcurrent protection,

Dual Full Bridge Mode or 6 A Continuous

undervoltage protection, and two-stage thermal

Current in Parallel Mode (12 A Peak)

protection. The DRV8412/32 have a current-limiting

• DRV8432 (power pad up): up to 2 x 7 A

circuit that prevents device shutdown during load

Continuous Output Current ( 2 x 12 A Peak) in

transients such as motor start-up. A programmable

Dual Full Bridge Mode or 14 A Continuous

overcurrent detector allows adjustable current limit

and protection level to meet different motor

Current in Parallel Mode (24 A Peak)

requirements.

• PWM Operating Frequency up to 500 kHz

The DRV8412/32 have unique independent supply

• Integrated Self-Protection Circuits Including

and ground pins for each half bridge, which makes it

Undervoltage, Overtemperature, Overload, and

possible to provide current measurement through

Short Circuit

external shunt resistor and support multiple motors

• Programmable Cycle-by-Cycle Current Limit

with different power supply voltage requirements.

Protection

Simplified Application Diagram

• Independent Supply and Ground Pins for Each

Half Bridge

• Intelligent Gate Drive and Cross Conduction

Prevention

• No External Snubber or Schottky Diode is

Required

APPLICATIONS

• Brushed DC and Stepper Motors

• Three Phase Permanent Magnet Synchronous

Motors

• Robotic and Haptic Control System

• Actuators and Pumps

• Precision Instruments

• TEC Drivers

DESCRIPTION

The DRV8412/32 are high performance, integrated

dual full bridge motor drivers with an advanced

protection system.

Because of the low R

DS(on)

of the H-Bridge MOSFETs

and intelligent gate drive design, the efficiency of

these motor drivers can be up to 97%, which enables

the use of smaller power supplies and heatsinks, and

are good candidates for energy efficient applications.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Copyright © 2009–2010, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.