Datasheet

TPS54311, TPS54312

TPS54313, TPS54314

TPS54315, TPS54316

SLVS416B − FEBRUARY 2002 − REVISED APRIL 2005

www.ti.com

10

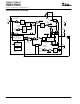

LAYOUT CONSIDERATIONS FOR THERMAL

PERFORMANCE

For operation at full rated load current, the analog ground

plane must provide adequate heat dissipating area. A 3

inch by 3 inch plane of 1 ounce copper is recommended,

though not mandatory, depending on ambient temperature

and airflow. Most applications have larger areas of internal

ground plane available, and the PowerPAD should be

connected to the largest area available. Additional areas

on the top or bottom layers also help dissipate heat, and

any area available should be used when 3 A or greater

operation is desired. Connection from the exposed area of

the PowerPAD to the analog ground plane layer should be

made using 0.013 inch diameter vias to avoid solder

wicking through the vias. Six vias should be in the

PowerPAD area with four additional vias located under the

device package. The size of the vias under the package,

but not in the exposed thermal pad area, can be increased

to 0.018. Additional vias beyond the ten recommended

that enhance thermal performance should be included in

areas not under the device package.

Minimum Recommended Exposed

Copper Area For Powerpad. 5mm

Stencils may Require 10 Percent

Larger Area

0.2454

0.0150

0.06

0.0256

0.1700

0.1340

0.0620

0.0400

0.0400

0.0400

0.0600

0.0227

0.0600

0.1010

6 PL ∅ 0.0130

4 PL ∅ 0.0180

Connect Pin 1 to Analog Ground Plane

in This Area for Optimum Performance

Minimum Recommended Top

Side Analog Ground Area

Minimum Recommended Thermal Vias: 6 × .013 dia.

Inside Powerpad Area 4 × .018 dia. Under Device as Shown.

Additional .018 dia. Vias May be Used if Top Side Analog

Ground Area is Extended.

0.2560

Figure 12. Recommended Land Pattern for 20-Pin PWP PowerPAD