Datasheet

TPS54311, TPS54312

TPS54313, TPS54314

TPS54315, TPS54316

SLVS416B − FEBRUARY 2002 − REVISED APRIL 2005

www.ti.com

8

APPLICATION INFORMATION

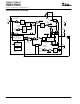

Figure 10 shows the schematic diagram for a typical

TPS54314 application. The TPS54314 (U1) can provide

up to 3 A of output current at a nominal output voltage of

1.8 V. For proper thermal performance, the PowerPAD

underneath the TPS54314 integrated circuit needs to be

soldered to the printed circuit board.

C2

RT

SS/ENA

VBIAS

PWRGD

VSENSE

1

2

3

4

5

6

7

9

VIN

PH

BOOT

PGND

PGND

PGND

PwrPAD

U1

TPS54314PWP

1

2

V

O

GND

J3

C7

0.047 µF

R1

10 kΩ

C11

1000 pF

1

J1

2

1

V

I

GND

+

1

Optional

71.5 kΩ

L1

5.2 µH

R7

8

10 11

12

13

14

15

16

17

18

19

20

AGND

NC

PH

PH

PH

PH

FSEL

VIN

VIN

C8

10 µF

C3

0.1 µF

+

C9

470 µF

4 V

PWRGD

Figure 10. TPS54314 Schematic

INPUT VOLTAGE

The input to the circuit is a nominal 5 VDC, applied at J1.

The optional input filter (C2) is a 220-µF POSCAP

capacitor, with a maximum allowable ripple current of 3 A.

C8 is the decoupling capacitor for the TPS54314 and must

be located as close to the device as possible.

FEEDBACK CIRCUIT

The output voltage of the converter is fed directly into the

VSENSE pin of the TPS54314. The TPS54314 is

internally compensated to provide stability of the output

under varying line and load conditions.

OPERATING FREQUENCY

In the application circuit, a 700 kHz operating frequency is

selected by leaving FSEL open and connecting a 71.5 kΩ

resistor between the RT pin and AGND. Different

operating frequencies may be selected by varying the

value of R3 using equation 1:

R +

500 kHz

Switching Frequency

100 kW

Alternately, preset operating frequencies of 350 kHz or

550 kHz my be selected by leaving RT open and

connecting the FSEL pin to AGND or VIN respectively.

OUTPUT FILTER

The output filter is composed of a 5.2-µH inductor and

470-µF capacitor. The inductor is a low dc resistance

(16-mΩ) type, Sumida CDRH104R−5R2. The capacitor

used is a 4-V POSCAP with a maximum ESR of 40 mΩ.

The output filter components work with the internal

compensation network to provide a stable closed loop

response for the converter.

PCB LAYOUT

Figure 11 shows a generalized PCB layout guide for the

TPS54311−16.

The VIN pins should be connected together on the printed

circuit board (PCB) and bypassed with a low ESR ceramic

bypass capacitor. Care should be taken to minimize the

loop area formed by the bypass capacitor connections, the

VIN pins, and the TPS54311−16 ground pins. The

minimum recommended bypass capacitance is 10-µF

ceramic with a X5R or X7R dielectric and the optimum

placement is closest to the VIN pins and the PGND pins.

The TPS54311−16 has two internal grounds (analog and

power). Inside the TPS54311−16, the analog ground ties

to all of the noise sensitive signals, while the power ground

ties to the noisier power signals. Noise injected between

the two grounds can degrade the performance of the

TPS54311−16, particularly at higher output currents.

Ground noise on an analog ground plane can also cause

problems with some of the control and bias signals. For

these reasons, separate analog and power ground traces

are recommended. There should be an area of ground one

the top layer directly under the IC, with an exposed area for

connection to the PowerPAD. Use vias to connect this

ground area to any internal ground planes. Use additional

vias at the ground side of the input and output filter

capacitors as well. The AGND and PGND pins should be

tied to the PCB ground by connecting them to the ground

area under the device as shown. The only components

(1)