Service Bulletin

Customer Service Bulletin

Commercial Business Group

Reelmaster

®

216 and 216-D Cutting Units

Model/Serial Range: Model Number: Serial Numbers:

03450 00000-99999

Subject: Weihle Roller (92-1846) bearing binds after adjustment.

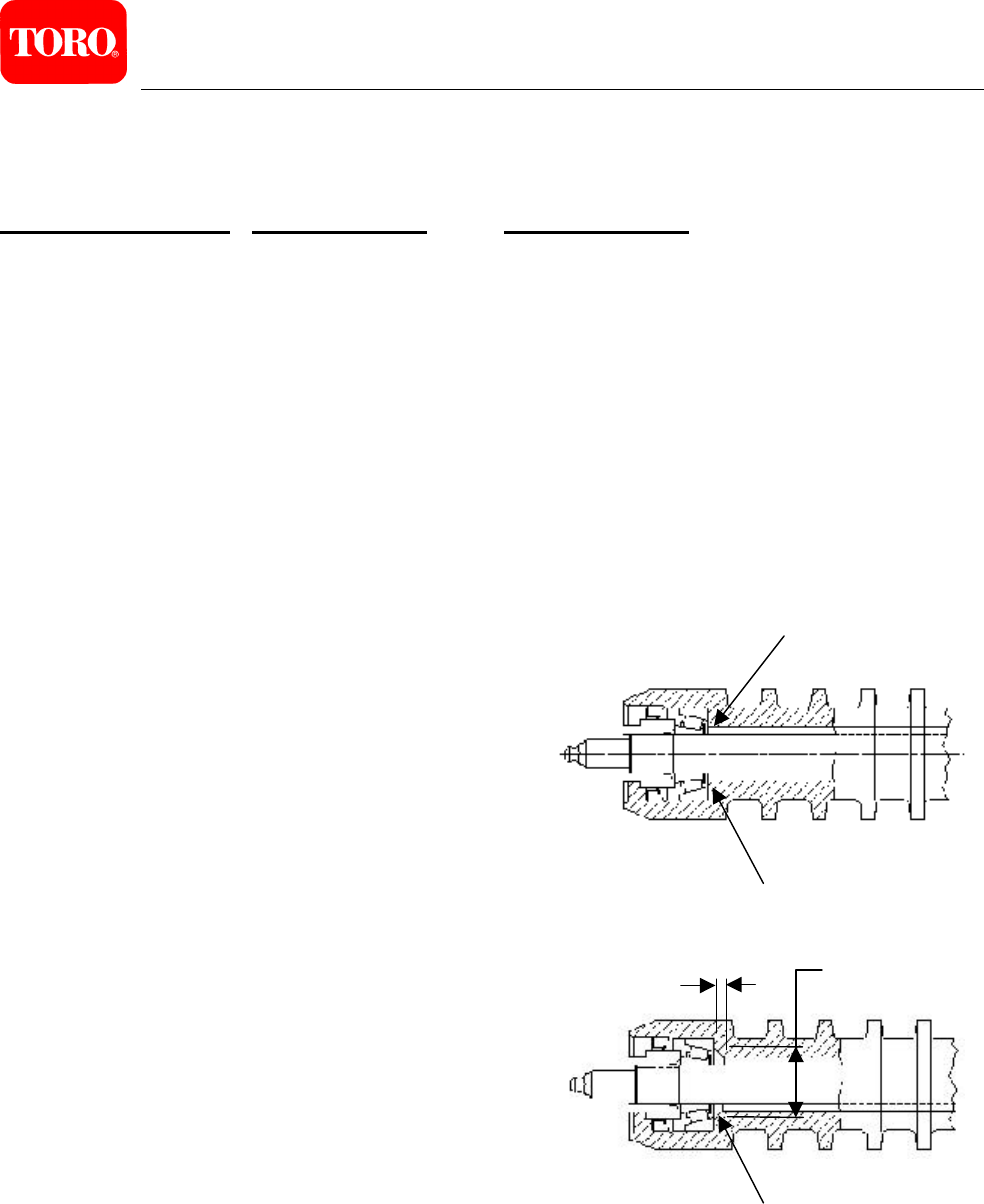

As the roller bearings are adjusted to compensate for wear, the bearing cage may make

contact with the roller housing. Contact between the bearing cage and the housing will

prevent the roller from rotating freely and could cause the roller to skid during operation.

Extended bearing performance and service life are possible, if a counter-bore is added as

described below.

REELMASTER 216 Wiehle Roller (92-1846)

To add Counter-bore (or chamfer):

1. Secure roller housing in a vice and remove

the roller shaft, seals, and bearings.

2. To simplify outer race removal, use an

electric arc welder to shrink the bearing

race. Only a small arc in one location on the

race is required.

3. Use a die grinder to grind a counter-bore as

shown in the illustration below. Counter-

bore should be 1

5

/

16

" (33 mm) diameter

and

1

/

16

-

1

/

8

" (1.5 - 3.0 mm) deep.

4. Clean grinding dust and debris from the

housing.

5. Assemble the roller using new replacement

bearings, races, seals, and nuts. Use a

press to seat the outer races into their

bores.

6. Tighten nuts while rotating the roller to seat

the bearing cone in position.

7. Loosen the nuts and then tighten again to

provide 5 in-lb (5.8 KgCm) rolling torque.

Contact may occur between

Bearing Cage and Roller

Counter-bore not present

1 5/16” (33mm)

1/16 -1/8 in.

(1.5-3.0mm)

Counter-bore added

Ref: 14-05 Copyright

, 1995. The Toro Company