Operator's Manual

Maintenance

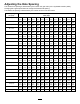

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Changethegearboxlubrication.

•Checkthetorqueofthecoringheadfasteners.

Beforeeachuseordaily

•Checkthebelttension.

•Checkthebelttension.

Every50hours

•Greasethebearingsandbushings.

•Inspectthebearings.

Every100hours

•Checkthegearboxlubrication.

Every250hours

•Changethegearboxlubrication.

•Checkthetorqueofthecoringheadfasteners.

Every500hours

•Inspectandreplacethebearingsasneeded.

Beforestorage

•Performall50-hourmaintenanceprocedures.

•Paintareasthatarescratched,chipped,orrusted.

•Removeandcleanthetines.

•Removealldebris.

Yearly

•Inspectthebelts.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Positionthemachineonalevelsurface.

–Movethethrottleswitchtothelow-idleposition.

–DisengagethePTO.

–Ensurethatthetractionisinneutral.

–Engagetheparkingbrake.

–Shutofftheengineofthetractionunitand

removethekey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

authorizedT orodistributor.

•Ensurethatthemachineisinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Donotcheckoradjustthechaintensionwhenthe

tractionunitengineisrunning.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Supportthemachinewithblocksorstoragestands

whenworkingbeneathit.Neverrelyonthe

hydraulicsystemtosupportthemachine.

•Checkthetinemountingboltsdailytobesurethat

theyaretightenedtospecication.

•Ensurethatallguardsareinstalledandthehood

issecuredshutaftermaintainingoradjustingthe

machine.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

28