Operator's Manual

Figure3

1.Pivotpin4.Brakereturnspring

2.Liftarm

5.Tab

3.Pivotbracket

6.Installthewheelandtireassembly.Torquethewheel

nutsto75–80ft-lb(102–108N-m).

7.Repeattheprocedureontheoppositesideofthe

machine.

3

ConnectingtheLiftArmsto

theCuttingUnit

Partsneededforthisprocedure:

1

Liftarm,right

1

Liftarm,left

4Thrustwasher-nylon

4

Clevispin

2Hairpin

2

Heightofcutcollar

2

Clevispin

2Hairpin

2

Capscrew,1/2x3/4inch

2Washer

Procedure

1.Movethecuttingunitintopositioninfrontofthe

tractionunit.

2.MovetheliftlevertotheFloatposition.Pushalift

armdownuntiltheholesintheliftarmlineupwith

theholesinthecastorarmbracketandtheheight

ofcutrodcanbeinsertedintotheliftarmpads

(

Figure4).

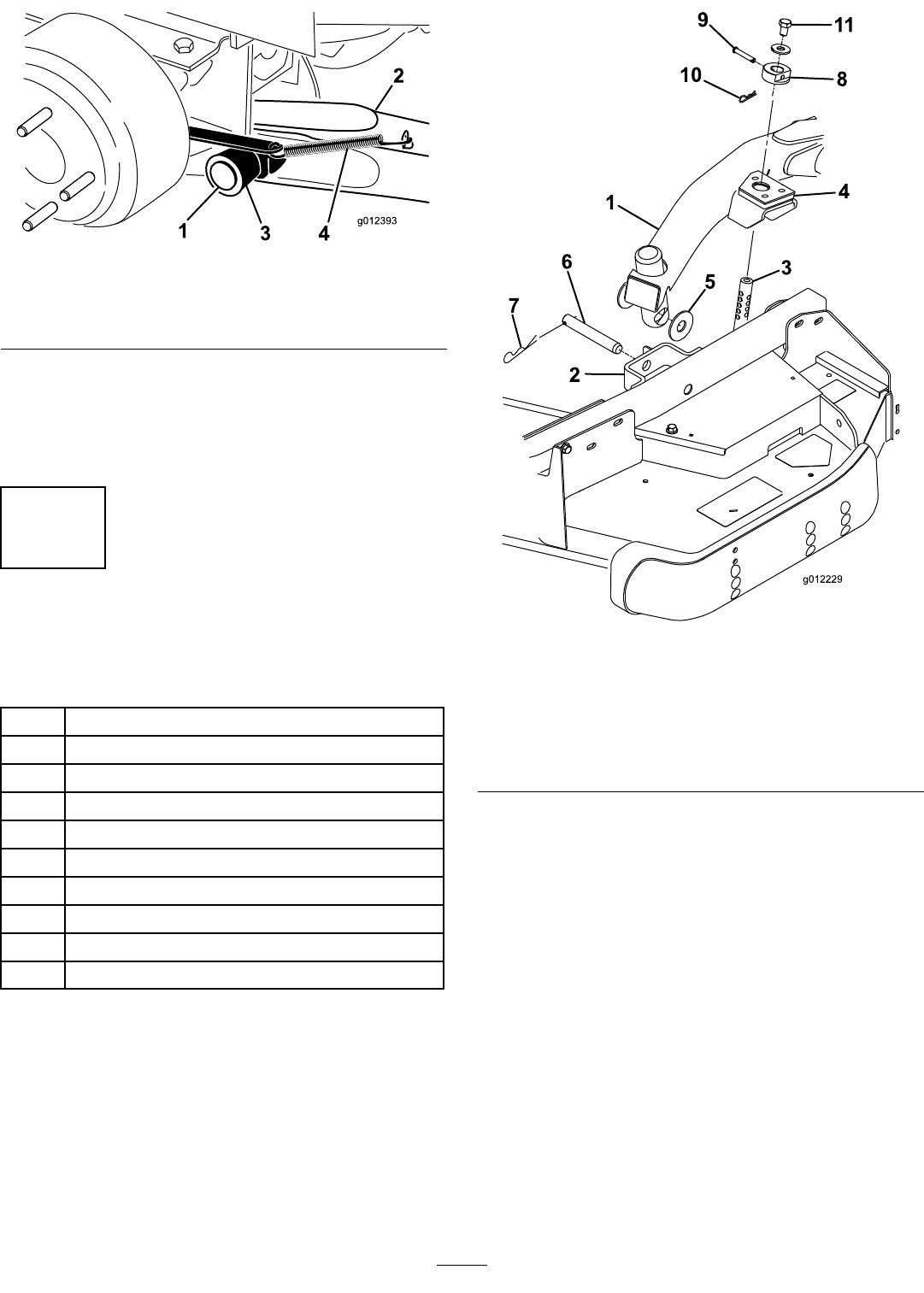

Figure4

1.Liftarm

7.Hairpincotter

2.Castorarmbracket8.Height-of-cutcollar

3.Height-of-cutrod9.Clevispin

4.Liftarmpads

10.Hairpincotter

5.Thrustwashers11.Bolt

6.Clevispin

3.Securetheliftarmtothecastorarmwith(2)thrust

washers,aclevispinandahairpincotter.Position

thethrustwashersbetweentheliftarmandthe

castorarmbracket(Figure4).Insertendofcotter

pinintotheslotinthecastorarmtabtoretaincotter

pin.

4.Repeattheprocedureontheoppositeliftarm.

5.Startthetractionunitandraisethecuttingunit.

6.Pushdownontherearofthecuttingunitandinsert

theheightofcutrodsthroughtheliftarmpads.

7.Installtheheightofcutcollarsontotheheightof

cutrodsandsecurewiththeclevispinsandhair

pincotters(Figure4).Headofclevispintobe

positionedtowardthefrontofthedeck.

8.Installa1/2x3/4inchboltandawashertotopof

eachheightofcutrod(Figure4).

10